Steam flow meter is a type of flowmeter that can effectively measure the mass flow and volume flow of steam. For example, in heating enterprises, the measurement of steam is related to important economic interests such as production costs and trade measurement. To maximize the accuracy of measurement, it is important to correctly design and select the appropriate steam flowmeter.

Based on Sino-Inst’s many years of experience, steam measurement can choose vortex flowmeter, orifice flowmeter, nozzle flowmeter, V-cone flowmeter, Venturi flowmeter, Annubar flowmeter, etc.

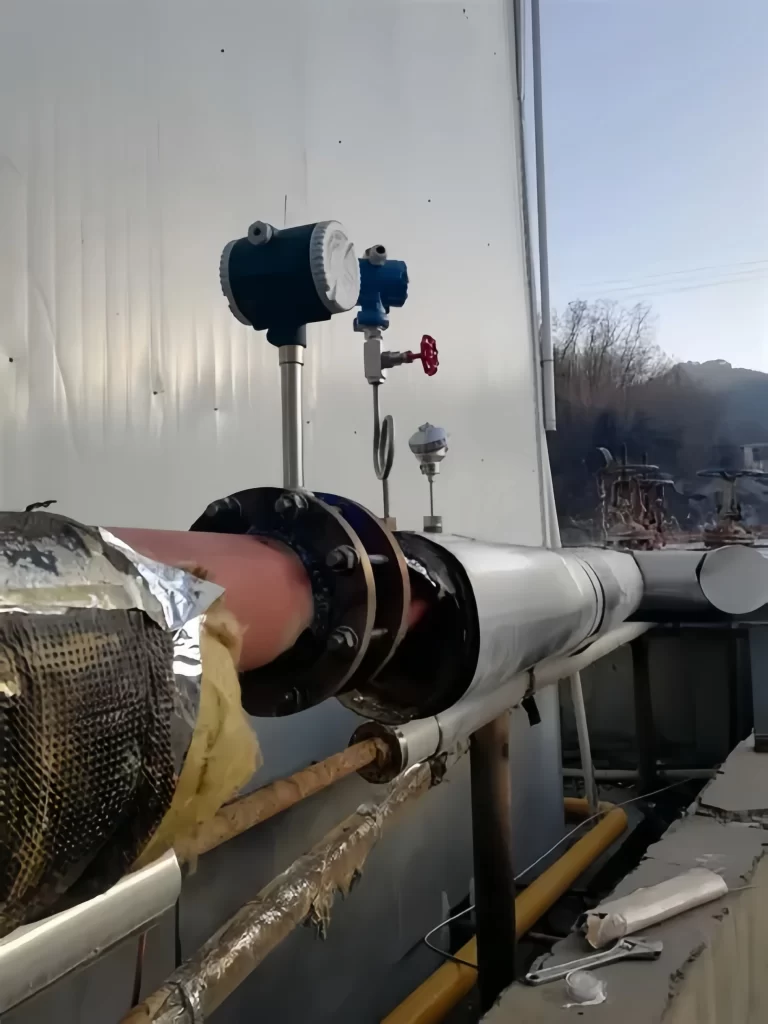

Sino-Inst supplies various types of steam flow meters, which can be used for flow measurement of saturated steam and superheated steam. High temperature, high pressure, ANSI flange connection, temperature and pressure compensation, etc. can be customized.

Featured Steam Flow Meters

Steam Flow Meter Is Becoming More Important

Steam is widely used as a source of power in the production of electricity. In today’s power plants, heat is obtained from multiple sources. These include fossil fuels, such as coal, natural gas, or oil, as well as other sources of heat, including nuclear fuel, waste fuels, solar energy, and geothermal energy.

The heat energy in these sources of heat is released, either through combustion or through a similar process. The heat is transferred to water, which generates steam. In many cases, this steam is then used to drive an electric generator. The system used to generate the steam is called a boiler.

As the costs of energy rise, many companies are looking to increase efficiencies in energy and power generation. As a result, more attention is being paid to steam flow measurement.

However, the high temperature, high pressure and phase change characteristics of steam make its flow measurement challenging.

Working Principles of Different Types of Steam Flow Meters

Next, we will introduce the working principles of several mainstream types of steam flow meters.

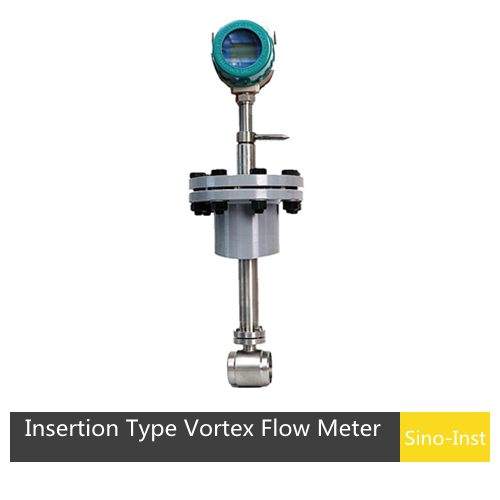

Vortex Flow Meter for Steam

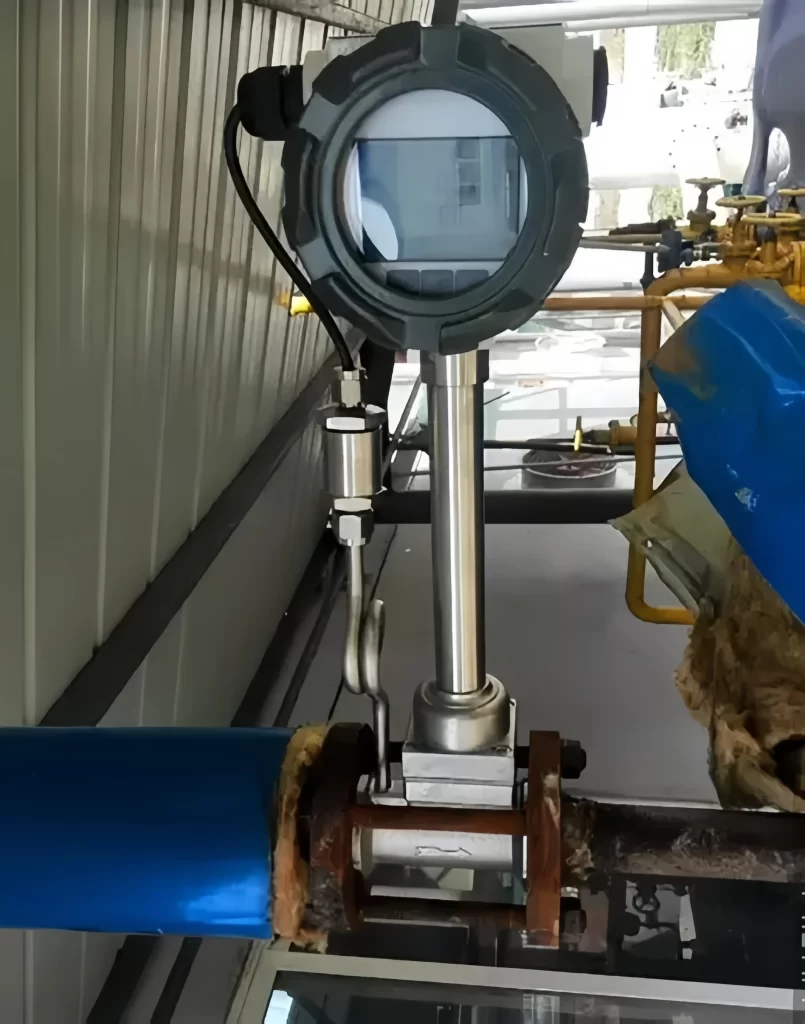

Vortex flowmeter is the preferred flowmeter for measuring steam. Whether measuring saturated steam or superheated steam, a vortex flowmeter can achieve efficient measurement.

Steam vortex flowmeter is based on the Karman vortex principle. When steam flows through the throttling part in the flowmeter, vortices will be generated alternately on both sides to form a vortex street. And the vortex frequency is linearly related to the steam flow rate within a certain range. With a simple structure without moving parts, stable and accurate measurement of high-temperature and high-pressure steam can be achieved.

More about: Vortex Flow Meter Technology

When the vortex flowmeter measures superheated steam, temperature and pressure compensation are required at the same time. Steam is generally settled in mass flow. Because any change in temperature or pressure will change the density of steam, and the mass flow will also change accordingly.

When the vortex flowmeter measures saturated steam, single temperature compensation or single pressure compensation is required. The density of saturated steam has a fixed correspondence with temperature or pressure (saturated steam density table). Knowing any of them, the density of saturated steam can be determined.

Read more about: What Is Temperature Compensation and Pressure Compensation for Flow Meters?

Differential Pressure Flow Meter for Measuring Steam

In the measurement of steam flow, differential pressure flowmeters are also widely used. Based on the Bernoulli equation and the flow continuity equation, the steam flow is determined by measuring the differential pressure generated by the throttling device (such as orifice plate, nozzle, V cone, etc.) in the steam pipeline.

The complete set of differential pressure flowmeters is composed of standard throttling devices, differential pressure transmitters and flow integrators from different manufacturers, so it is flexible and convenient to use.

Rotary Vane Steam Flow Meter

The rotary vane steam flowmeter is widely used in the measurement of saturated steam in small and medium-sized enterprises. It is a purely mechanical measuring instrument.

The measured steam is throttled by the orifice plate when it flows through the body of the rotary vane steam flowmeter. Under the action of the front and rear pressure difference, a part of the steam enters the nozzle of the diverter pipe through the nozzle. Then the jet formed drives the impeller at the upper end of the rotor shaft to rotate.

The speed of the impeller is proportional to the mass flow rate of the measured steam flowing through the flowmeter. Through correction and division, the actual flow rate of the accumulated steam is reflected by the indicator dial.

Target Flow Meter

The target flowmeter consists of a detection (sensing) and conversion part. The detection part includes a circular target placed in the center of the pipe, a lever, a sealing diaphragm and a measuring tube.

When steam flows through the target, the target is subjected to a force mainly formed by the dynamic pressure of the fluid and the throttling effect of the target on the fluid. There is a certain relationship between this force and the flow rate. By measuring the force on the target, the fluid flow rate and flow rate can be calculated.

It is used to measure the flow of various dirty, corrosive, high-temperature, high-pressure liquids, gases and steam in the production process to ensure the stability of the production process.

After understanding the different types of steam flow meters, you can start to choose the appropriate steam flow meter based on your actual measurement needs.

Steam Flow Meter Selection Guide

When choosing a steam flowmeter, the following factors should be considered:

More Flow Measurement Solutions

Sino-Inst is a Professional steam flow meters manufacturer and supplier. Sino-Inst offers over 10 steam flow meter products. About 70% of these are vortex. Differential pressure flow meters are also widely used.

A wide variety of steam flow meter options are available to you, such as free samples, paid samples. Sino-Inst’s steam flow meters service for industrial applications, like: Industrial gas, corrosives and brine, chemical processing, energy, electronics, laboratories, medical, and many other industries.

Sino-Inst sells through a mature distribution network that reaches all 50 states and 30 countries worldwide. If you need to purchase steam flow meters, or have customization requirements, please feel free to contact us!

-1.jpg)