Rotary Paddle Level Switch (controller) is a process instrument used to control the material level in open containers or closed and micro-pressure containers. When the material level reaches the high or low limit, the micro switch contacts of the controller output an alarm or control signal.

Sino-Inst Rotary Paddle Level Switch (controller) can be installed in any shape of bins, buckets, tanks and other containers to measure most solid materials.

Features

- Due to the mechanical detection method, there is no complicated circuit amplification part, and no adjustment is required after installation;

- The internal structure can be easily disassembled for inspection and maintenance;

- It has excellent durability, good reproducibility and extremely stable performance due to no torque loss;

- The torque can be adjusted simply;

- Even if the blade is subjected to excessive force, the motor can be protected by the slip mechanism;

- No malfunction caused by environmental factors such as temperature, humidity, and adhesion will occur;

- Due to the small number of parts, spot welding and riveting, it is particularly resistant to vibration;

- The main shaft adopts multiple seals to completely prevent the intrusion of dust;

- The sealed structure is used, which can be used in open air environments;

- It adopts explosion-proof form, suitable for explosion-proof ExdIIBT4 level occasions;

Rotary Paddle Level Switch-Controller Technical Parameters

| Power supply: | AC220V, AC110V, DC24V |

| Power consumption: | 3W |

| Contact capacity: | 5A AC250V SPDT (single pole double throw) |

| Blade speed: | 1rpm (rev/min) |

| Torque: | 10Kg.cm (1.0Nm) |

| Material density: | ≥0.5Kg/cm3 |

| Ambient temperature: | -10~+80℃ |

| Working temperature: | Normal temperature: -10~+80℃ High temperature can reach up to 450℃ |

| Working pressure: | 0~0.2Mpa |

| Measuring range: | Ordinary type <0.5m, default standard 100m; shaft protection type 0.3~3m; soft cable type 1~30 meters |

| Insulation resistance: | ≥100MΩ (DC500V) |

| Blade material: | SUS304 (0Cr18Ni9Ti) |

| Protection level: | IP65 |

| Explosion-proof level: | ExdIIBT4 |

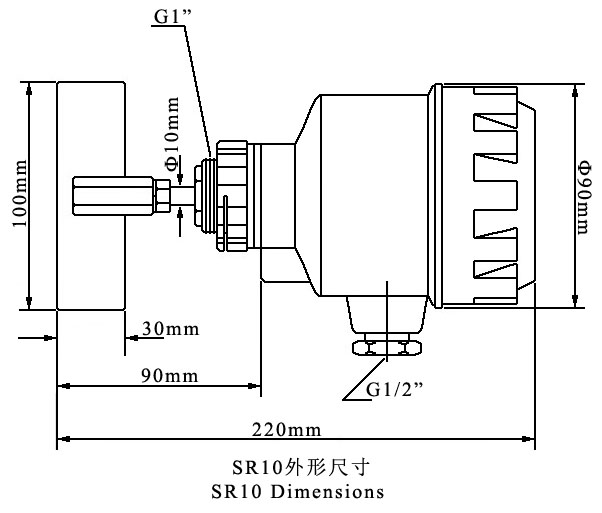

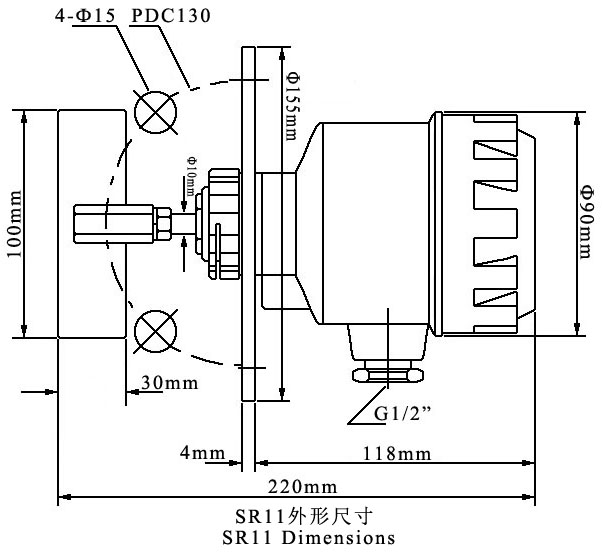

| Installation form: | Standard type G1” external thread (other specifications can be customized); small anti-rotation G3/4” external thread; flange type 2.5” PN0.6 factory standard flange (other specifications can be customized); |

| Electrical interface: | M20X1.5 |

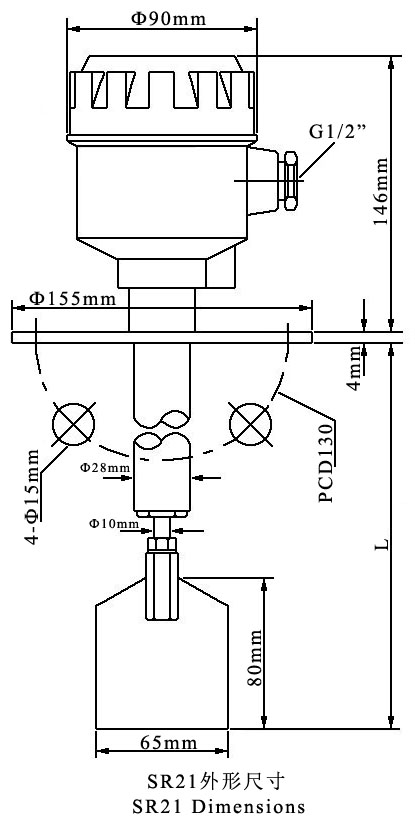

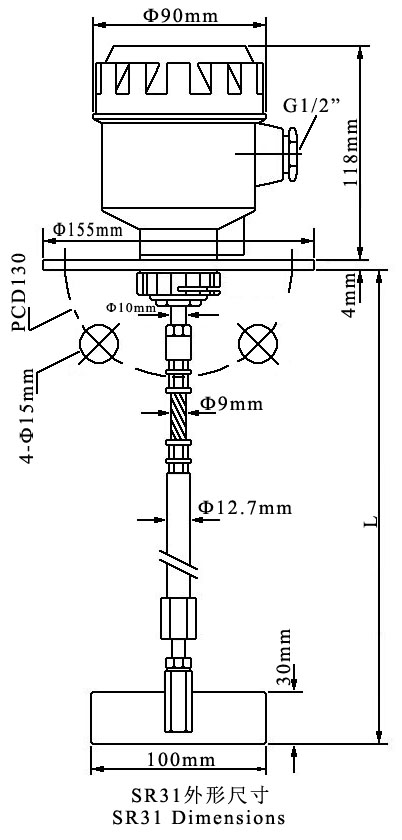

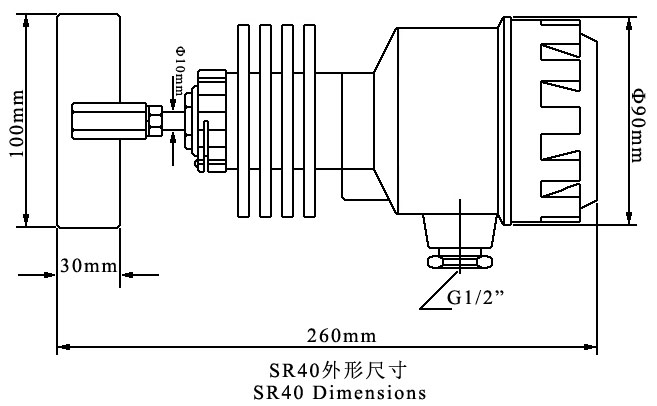

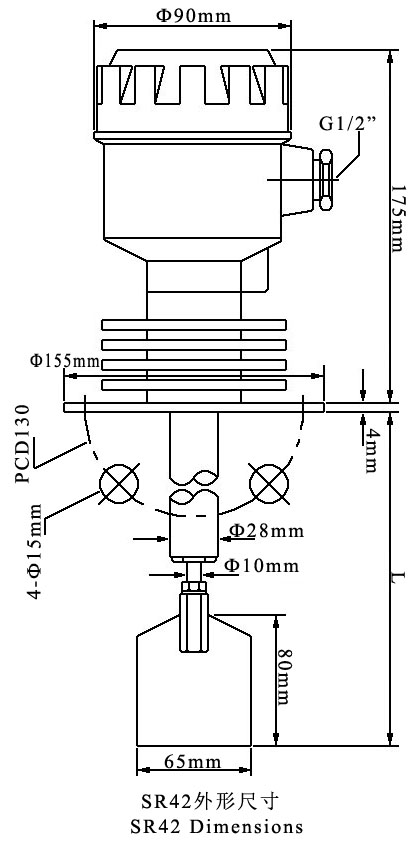

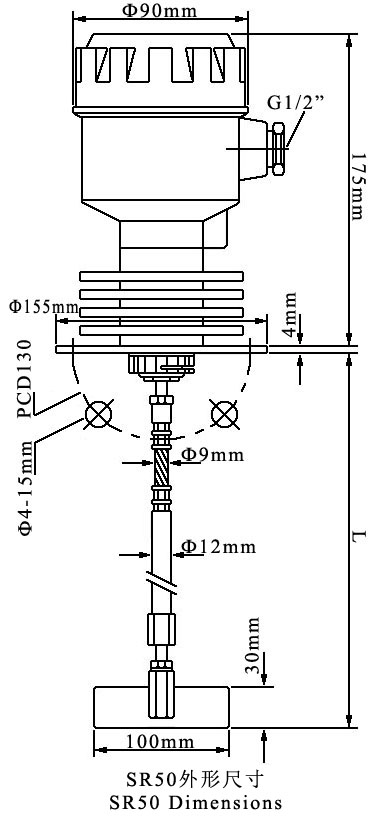

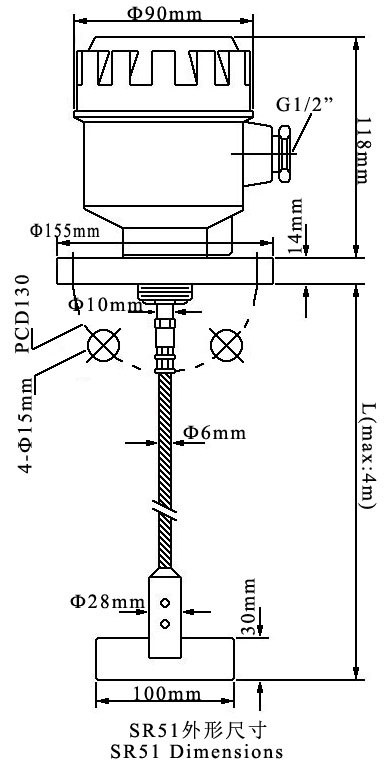

Dimensions-Customizable

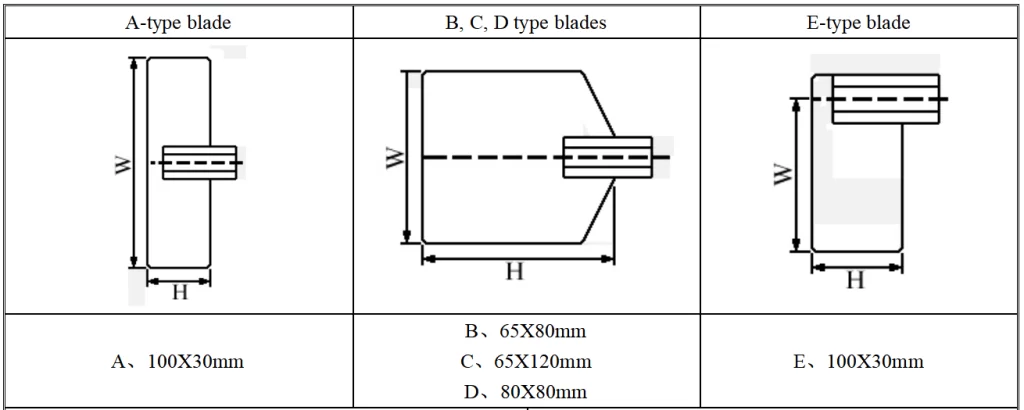

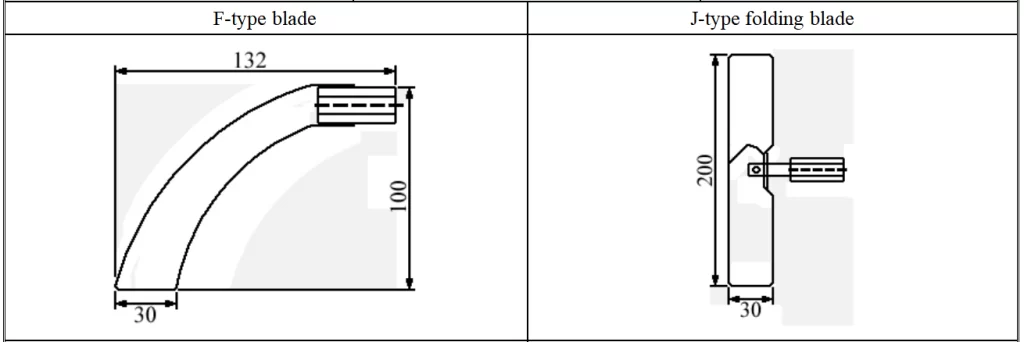

Blade size:

Different types of external dimensions:

- Junction box specifications: aluminum alloy (IP65)

- Power consumption: 4W

- Output contact: 5A/250VAC SPDT

- Speed: 1R.P.M

- Operating temperature: -10~+60℃

- Applicable specific gravity: 0.5g/cm3

- Thread specification: G1″

- Junction box specifications: aluminum alloy (IP65)

- Power consumption: 4W

- Output contact: 5A/250VAC SPDT

- Speed: 1R.P.M

- Operating temperature: -10~+60℃

- Applicable specific gravity: 0.5g/cm3

- Flange specifications: DN65 PN0.6

- Junction box specifications: aluminum alloy (IP65)

- Power consumption: 4W

- Output contact: 5A/250VAC SPDT

- Speed: 1R.P.M

- Operating temperature: -10~+60℃

- Applicable specific gravity: 0.5g/cm3

- Connection size: flange DN65 PN0.6; thread 2-1/2″

- Junction box specifications: aluminum alloy (IP65)

- Power consumption: 4W

- Output contact: 5A/250VAC SPDT

- Speed: 1R.P.M

- Operating temperature: -10~+60℃

- Applicable specific gravity: 0.5g/cm3

- Connection size: flange DN65 PN0.6; thread 2-1/2″

- Junction box specifications: aluminum alloy (IP65)

- Power consumption: 4W

- Output contact: 5A/250VAC SPDT

- Speed: 1R.P.M

- Operating temperature: -10~+200℃

- Applicable specific gravity: 0.5g/cm3

- Connection size: flange DN65 PN0.6; thread 2-1/2″

- Junction box specifications: aluminum alloy (IP65)

- Power consumption: 4W

- Output contact: 5A/250VAC SPDT

- Speed: 1R.P.M

- Operating temperature: -10~+200℃

- Applicable specific gravity: 0.5g/cm3

- Connection size: flange DN65 PN0.6; thread 2-1/2″

- Junction box specifications: aluminum alloy (IP65)

- Power consumption: 4W

- Output contact: 5A/250VAC SPDT

- Speed: 1R.P.M

- Operating temperature: -10~+200℃

- Applicable specific gravity: 0.5g/cm3

- Connection size: flange DN65 PN0.6; thread 2-1/2″

- Junction box specifications: aluminum alloy (IP65)

- Power consumption: 4W

- Output contact: 5A/250VAC SPDT

- Speed: 1R.P.M

- Operating temperature: -10~+60℃

- Applicable specific gravity: 0.5g/cm3

- Connection size: flange DN65 PN0.6; thread 2-1/2″

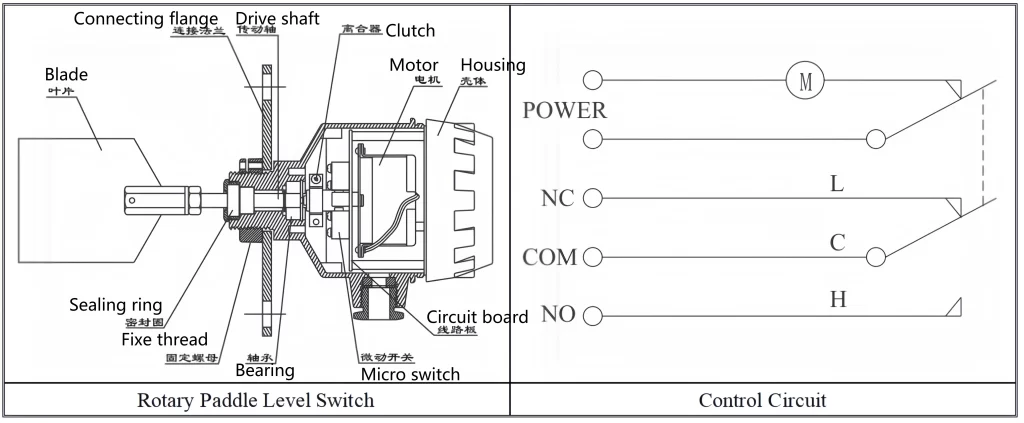

Rotary Paddle Level Switch Working Principle

The Rotary Paddle Level Switch uses a permanent magnet motor to drive the blade to rotate. When the material being detected rises to the blade position, the blade is blocked from rotating. The resistance is transmitted to the detection device in the junction box. The detection device outputs a switch signal (NO, COM) to the outside. The power is cut off to stop the blade from rotating.

When the material level drops, the resistance disappears when the blade is not blocked from rotating. The detection device returns to its original state by the tension of the spring. Turn on the power (NC, COM). The permanent magnet motor drives the blade to start rotating. Adjust the tension of the spring for materials with different specific gravities. When the specific gravities are large, the spring tension is adjusted to the strongest. Otherwise, it is adjusted to the weakest.

Featured Applications

Sino-Inst Rotary Paddle Level Switch (controller) can be installed in any shape of silo, bucket, tank and other containers to measure most solid materials.

Widely used in places with blocky or powdery solid materials such as feed, flour, leather, abrasives, soil, stone, wood, rubber, beans, calcium powder, sand, pills, sawdust, coal, synthetic resin, grain, limestone, mixed sand, metal, salt, etc.

- In the chemical industry, Rotary Paddle Level Switch is usually used to monitor the liquid level of liquid or solid chemical materials in reactors, pipelines or storage tanks. By real-time monitoring of the position of materials, the safety and stability of the production process can be ensured.

- In the oil and gas industry, Rotary Paddle Level Switch is widely used in storage equipment such as oil tanks and gas tanks. It is used to monitor the liquid level of materials such as crude oil, gas, petrochemical products, etc., so as to manage and control them reasonably.

- In the food processing and beverage industry, Rotary Paddle Level Switch is often used to monitor the material level of food raw materials such as grains, sugar powder, milk powder, etc. during the production process. Ensure the continuous operation of the production line and the stability of product quality.

- In the field of water treatment, Rotary Paddle Level Switch can be used to monitor the liquid level of overflow, clarification tank, dosing device and other parts in sewage treatment plants and water treatment equipment. So as to timely adjust and control the water treatment process.

- In the pharmaceutical and medical industries, Rotary Paddle Level Switch can be used to monitor the liquid level of pharmaceutical raw materials, liquid medicines, etc. in pharmaceutical equipment or pharmaceutical storage devices. Ensure the compliance and quality of pharmaceutical production.

Order Guide

| SR— | Rotary paddle level switch | ||||||||||

| SR—X | Small Rotary Paddle Level Switch | ||||||||||

| 10 | Standard thread type | Installation form | |||||||||

| 11 | Standard flange type | ||||||||||

| 20 | Shaft protection tube thread type | ||||||||||

| 21 | Shaft protection tube flange type | ||||||||||

| 30 | Shaft length adjustable thread type | ||||||||||

| 31 | Shaft length adjustable flange type | ||||||||||

| 40 | High temperature thread type | ||||||||||

| 41 | High temperature flange type | ||||||||||

| 42 | High temperature protection sleeve type | ||||||||||

| 50 | Wire rope thread type | ||||||||||

| 51 | Wire rope flange type | ||||||||||

| A | AC220V | Supply voltage | |||||||||

| B | AC110V | ||||||||||

| C | DC24V | ||||||||||

| S | Special power supply | ||||||||||

| A | 100X30(WXH) | Leaf type | |||||||||

| B | 65X80(WXH) | ||||||||||

| E | 50X30(WXH) | ||||||||||

| F | Sickle type | ||||||||||

| S | Special type | ||||||||||

| — | Numbers | Insertion depth (including blades) | |||||||||

| EX | ExdIIBT4 | Explosion-proof grade | |||||||||

| SR— 10 A A 300 (Selection example) | |||||||||||

| Standard insertion depth 100mm (optional) | |||||||||||

More Featured Level Measurement Solutions

- Dry Materials-Bulk Solids-Powder Level Sensors Guide

- Role of Hydrostatic Level Transmitters In Well Water Level Monitoring Process

- Water Level Pressure Transducers

- Typical Ultrasonic Level Sensor Applications and Advantages

- Different Diesel Level Sensors for Diesel Tank Level Measurement

- Featured 5 Guided Wave Radar Level Transmitter Types

- Guided Wave Radar Level Transmitter Installation Guide and Troubleshooting

- Difference Between Radar and Guided Wave Radar Level Transmitter

- Hydrostatic Level Measurement-Liquid Level Measurement with Pressure Sensors

Rotary Paddle Level Switch plays an important role in industrial production and related fields. Through real-time monitoring of material level and material level, it can help enterprises reduce production costs and improve production efficiency. And ensure the safety and stability of the production process.

Sino-Inst produces and supplies a full range of Rotary Paddle Level Switch (controller). Accepts customization of insertion depth, temperature, installation size, etc. If you need to purchase, or have related technical questions, please feel free to contact us.

Rotary Paddle Level Switch-Controller for Grains, Powders

Rotary Paddle Level Switch (controller) is a process instrument used to control the material level in open containers or closed and micro-pressure containers. When the material level reaches the high or low limit, the micro switch contacts of the controller output an alarm or control signal.

Product SKU: Rotary Paddle Level Switch-Controller

Product Brand: Sino-Ins

Product Currency: USD

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)