Gas turbine flow meter is a precision metering instrument used for gas flow measurement. Especially in natural gas transportation and trade settlement, the gas turbine flow meter is even more popular.

Gas Turbine Flow Meter integrates temperature, pressure, and flow sensors. It is also equipped with an electronic volume corrector, which can simultaneously detect and display the flow rate and total amount under working conditions and standard conditions. It is widely used in the measurement of natural gas, coal gasification, propane, liquefied gas, and light hydrocarbon gas.

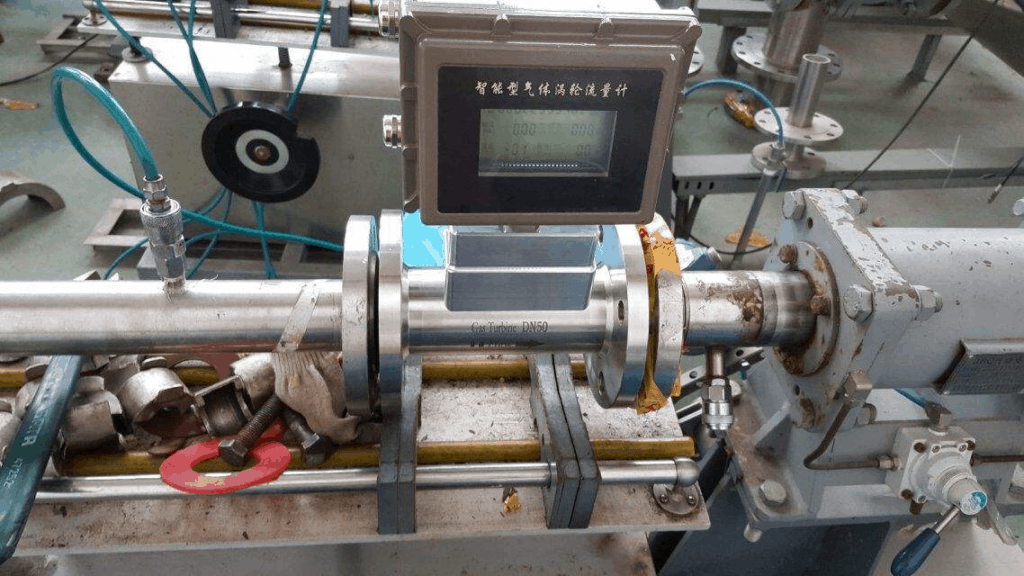

Featured GAS Turbine Flow Meter

| Measured medium | Impurity-free, medium and low flow rate gas | |||

| Implementation standard | Measurement of gas flow in closed pipelines – turbine flow sensor (GB/T18940-2003) | |||

| Verification procedure | Turbine flowmeter (JJG1037-2008) | |||

| Instrument diameter and connection method | Flange connection type | Stainless steel body | DN25~DN300 | |

| Aluminum body | DN25\DN50\DN80\DN100 | |||

| Carbon steel | DN350\DN400 | |||

| Threaded connection type | Stainless steel body (non-temperature and pressure compensation type) | DN25\DN40\DN50 | ||

| Stainless steel body (temperature and pressure compensation type) | DN25\DN40 | |||

| Flange standard | Conventional standards | GB/T9113-2000 | ||

| Other standards | International pipe flange standards | Such as German standard DIN, American standard ANSI, Japanese standard JIS | ||

| Domestic pipe flange standards | Such as Ministry of Chemical Industry standard, Ministry of Machinery standard | |||

| Thread specification | Conventional specifications | British pipe threads (external threads) | ||

| Other specifications | Internal threads, spherical threads, NPT threads, etc. | ±1%R (customization required) | ||

| Accuracy level and corresponding repeatability | Accuracy level | ±1.5%R | ±1%R (customization required) | |

| Repeatability | ≤0.5% | ≤0.15% | ||

| Range ratio | 30:1~10:1 | |||

| Verification conditions | Identification device | 1. Standard meter method gas flow calibration device; 2. Sonic nozzle gas flow calibration device; 3. Bell-type gas flow calibration device | ||

| Environmental conditions | Ambient temperature | 20℃ | ||

| Relative humidity | 75% | |||

| Usage conditions | Medium temperature | -30℃~+80℃ | Atmospheric pressure | 86KPa~106KPa |

| Ambient temperature | -20℃~+60℃ | Relative humidity | 5%~90% | |

Turbine Gas Flow Meters Types

Structure and working principle of gas turbine flowmeter

When gas enters the flowmeter, it first passes through the leading fluid of the independent movement and accelerates. Under the action of the fluid, the turbine blades are at a certain angle to the flow direction of the fluid. At this time, the turbine generates a torque and starts to rotate after the turbine overcomes the resistance torque and friction torque.

When the torques are balanced, the speed is stable. The angular velocity of the turbine rotation is linearly related to the flow rate. The magnet on the rotating signal disk periodically changes the magnetic resistance of the sensor. Thus, a pulse signal proportional to the volume flow of the fluid is sensed at both ends of the sensor.

The signal is amplified and shaped by the preamplifier and is simultaneously transmitted to the volume corrector for processing with the pressure and temperature signals detected by the pressure sensor and temperature sensor. The standard volume flow rate and the total volume under standard conditions are directly displayed.

The flow integrator consists of a temperature and pressure detection analog channel, a flow sensor channel and a microprocessor unit. It is also equipped with an external output interface to output various signals.

The microprocessor in the flowmeter performs temperature and pressure compensation according to the gas state equation. And automatically corrects the compression factor. The gas state equation is as follows:

Qn= Zn/Zg* Pg/pn * Tn/Tg * Qg

Where:

- Qn — Volume flow rate under standard conditions (m3/h)

- Zn— Gas compressibility coefficient under standard conditions

- Zg— Gas compressibility coefficient under working conditions

- Pg— Pressure under working conditions (absolute pressure, kPa)

- Pn— Absolute pressure value under standard conditions (kPa)

- Tn— Absolute temperature under standard conditions (293.15K)

- Tg— Absolute temperature under medium working conditions (273.15+t)K. Where t is the Celsius temperature of the measured medium (℃)

- Qg— Uncorrected volume flow rate (m3/h)

Note: For natural gas, Zn/Zg= (Fz)², Fz is called the supercompression factor. Calculate according to AGA NX-19 formula or SGERG-88 equation (see GB/T17747.3).

Advantages and Disadvantages of Gas Turbine Flow Meter

Main Benefits

- Adopting advanced micro-power high-tech, the whole machine has low power consumption. It can be powered by internal batteries for a long time, and can also be powered by external power.

- The flow meter head can be rotated 180°, and it is easy to install and use.

- High accuracy, generally up to ±1.5%R, ±1.0%R.

- Good repeatability, short-term repeatability can reach 0.05%0.2%R. It is precisely because of its good repeatability that it is the preferred flow meter in trade settlement.

- It can detect the temperature, pressure and flow of the measured gas. It can automatically track and compensate the flow. And display the gas flow under standard conditions (Pn=101.325KPa, Tn=293.15K).

- It can query temperature, pressure, time, date and other data in real time.

Main Disadvantages

- To maintain the calibration characteristics for a long time, regular calibration is required.

- Suspended matter or corrosive components contained in the medium will cause problems such as bearing wear and jamming. It will change its accuracy and limit its application range. Although the situation has improved after the use of wear-resistant carbide shafts and bearings, this problem still exists.

- Regularly add oil to ensure sufficient lubrication of the bearings to ensure metering accuracy and extend service life.

Why Prefer Natural gas turbine flow meter?

Natural gas is a clean energy source and plays an important role in the status of energy security. Gas turbine flow meter has become a widely used natural gas flow meter due to its obvious advantages in accuracy, simple repeatability, temperature drift and range ratio.

Equipped with a secondary instrument with specific functions, it can also accurately measure and alarm for over-volume. Therefore, it has been widely used in the fields of oil, natural gas, pipeline gas, etc.

Sino-Inst’s gas turbine flow meter has been widely used in gas metering for online metering and circuit metering. People prefer to choose gas turbine flow meter as the preferred instrument for natural gas measurement, mainly because of its advantages.

- Measurement and compensation

Natural gas turbine flow meter can measure the temperature and pressure of the medium in real time. And perform temperature compensation and automatic correction of extrusion factor for flow.

- Advanced technology

The gas turbine flow meter adopts advanced microcomputer technology and high-performance main chip. The LCD display is used to facilitate reading and output of pulse signals, and can also output 4-20mA standard video signals.

- High production efficiency

There is a communication interface, which can be used for serial communication. One configuration software can communicate with multiple flow meters for convenient centralized storage.

More Featured Gas Flow Measurement

- 4-20mA Flow Meters | Flow Meter Signal Output Guide

- Analog Flow Meters: An Encompassing Guide

- Approaches To Gas Flow Measurement: Types and Applications Of Gas Flow Meters

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Liquid and Gas NH3 Ammonia Flow Meters

- What Is Temperature Compensation and Pressure Compensation for Flow Meters?

- Application Case: Mass Flow Meter Measures Lime Slurry Flow and Density

- Guide: Types of Mass Flow Meters

The turbine flow meter is a velocity flow meter that measures the speed of the turbine to calculate the gas flow rate. It has the advantages of high measurement accuracy, fast response speed, and good stability.

Gas Turbine Flow Meters supplied by Sino-Inst are widely used to measure various gases such as natural gas, nitrogen, air, city gas, propane, butane, etc.

However, it should be noted that the turbine flow meter has certain requirements for the cleanliness of the measured gas. And it is not suitable for low flow rate and large fluctuation conditions.

If you need to purchase Gas Turbine Flow Meter, or have related technical questions, please feel free to contact our sales engineer!

-1.jpg)