What is a turbine flow meter? A turbine flow meter is a velocity flowmeter that measures flow rate by utilizing the fluid to drive the turbine rotor. It has the characteristics of easy maintenance, large flow capacity, and relatively low price. Sino-Inst’s turbine flow meters are widely used to measure petroleum, organic liquids, natural gas, etc.

Featured Turbine Flow Meters

Turbine Flow Meter Working Principle

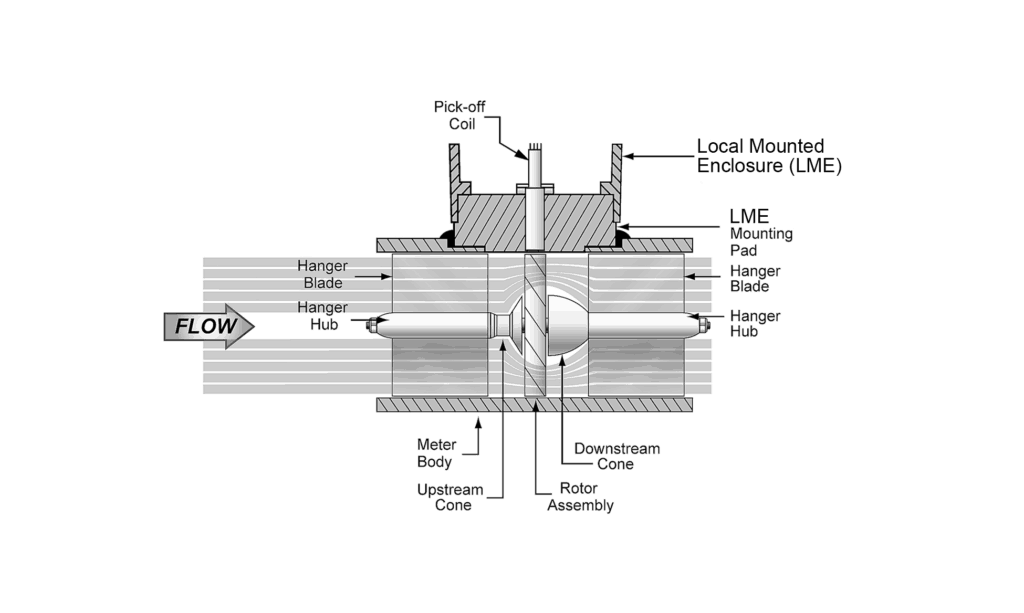

A turbine flowmeter is a typical velocity flowmeter, primarily used to measure the volumetric flow rate of liquids and gases in closed pipes.

A turbine flowmeter primarily consists of a turbine, a housing, and an electronic display. Its core measuring component is a turbine rotor equipped with multiple blades. Gas turbine flowmeters also have pressure and temperature sensors for temperature and pressure compensation.

When the measured fluid flows through the turbine flowmeter sensor, the impeller is forced to rotate by the fluid. The rotational speed varies with the flow rate. A magnetoelectric converter then converts the turbine speed into an electrical pulse signal of the corresponding frequency. After amplification by an amplifier circuit, the signal is processed by a microprocessor and then displayed on a display module.

Within a certain fluid velocity range and when the flow is turbulent, the turbine rotational speed (rotational speed) is directly proportional to the average flow velocity of the fluid. This is a critical linear relationship that underlies the turbine flowmeter’s accurate measurement. This relationship can be simplified as: n = K * v (where n is the turbine speed, v is the average flow velocity, and K is the meter constant).

Read more about: What Is Turbine Flow Meter K Factor?

Turbine Flow Meter Advantages and Disadvantages

Advantages:

High Accuracy: Gas turbine flowmeters offer accuracy levels of ±1.5%R and ±1.0%R; liquid turbine flowmeters offer accuracy levels of ±1%R, ±0.5%R, and ±0.2%R (customizable).

Good Repeatability: Short-term repeatability can reach 0.05%. Frequent calibration can achieve very high accuracy, achieving ideal results in both quantitative dispensing and quantitative barrel filling.

Output Pulse Frequency Signal: Signal processing with batch controllers and flow indicators virtually eliminates errors.

Wide Range: Liquid turbine flowmeters offer a turndown ratio of 10:1 to 20:1; gas turbine flowmeters offer turndown ratios of 1:10, 1:20, and 1:30.

Fast Response: Low inertia and a time constant of 1ms to 50ms. For pulsating flows with low rates of change, the introduced error is negligible.

Simple Structure: Compact and lightweight, easy to install and maintain, and boasts high flow capacity. High

Pressure and Corrosion-Resistant: Suitable for measuring high-pressure fluids. The sensor is made of corrosion-resistant materials and is resistant to general corrosive media.

Adaptable: A closed structure is possible, and the speed signal is measured non-contact, making it easy to implement a high-pressure design.

Disadvantages:

Regular calibration is required: Calibration characteristics cannot be maintained over time, and the calibration cycle is generally two years.

Affected by fluid properties: Fluid properties (density, viscosity) have a significant impact on flow characteristics. Compensatory measures must be taken based on the degree of impact.

Sensitive to velocity distribution distortion and rotational flow: The flowmeter is significantly affected by velocity distribution distortion and rotational flow. Long straight pipe sections are required upstream and downstream of the sensor; theoretically, the upstream straight pipe section should be greater than 10D.

Unsuitable for measuring pulsating and mixed-phase flows: Measurement accuracy is affected under pulsating and mixed-phase flow conditions.

High requirements for the cleanliness of the measured medium: While filters can be installed to accommodate dirty media, this increases pressure loss and maintenance requirements.

Pressure loss: Within the turbine flowmeter, gas flowing through the blades causes a certain amount of pressure loss. Especially at high flow rates, this can affect the pressure balance in the system.

Flow noise: Gas turbine flowmeters may generate some flow noise as high-speed gas flows through the blades. Noise control measures are necessary, especially in applications where environmental noise requirements are high.

Types of Turbine Flowmeters

Turbine flowmeters can be categorized by flowmeter structure, measured medium, and installation method.

Turbine Flow Meter Straight Run Requirement

Turbine flowmeters require straight pipe sections to ensure fluid flow stability and measurement accuracy, avoiding errors caused by vortexes and uneven velocity distribution.

For liquid turbine flowmeters, Upstream straight pipe section:

- General requirement: At least 20D (D is the pipe diameter).

- Upstream elbows: One 90° elbow requires at least 20D; two 90° elbows in different planes require at least 40D.

- Concentric expansion pipe section: At least 25D.

- Upstream regulating valves and half-open valves: At least 50D.

- Concentric contraction fully open valves: At least 15D upstream.

- Two 90° elbows in the same plane: At least 25D.

Downstream straight pipe section: At least 5D to ensure that the fluid passes fully through the impeller and is discharged stably.

For gas turbine flowmeters, the flowmeters have a dedicated rectifier with superior performance, so the straight pipe section requirements are lower. Only the upstream straight pipe section > 2DN and the downstream straight pipe section > 1DN are required. It is suitable for installation methods such as elbows, reducers, and pressure regulating valves in front of the front straight pipe section.

FAQ

More Flow Measurement Solutions

Turbine flow meters are widely used in industries such as petroleum, chemical, metallurgy, water supply, and papermaking. They provide flow measurement, process control, energy management, and environmental monitoring.

Sino-Inst offers a wide range of gas and liquid turbine flowmeters. We support customization of measurement parameters, including temperature, pressure, material, and signal output. With years of experience in fluid measurement, our turbine flowmeters are widely used in various industries across various countries.

If you need to purchase a turbine flow meter, please feel free to contact our sales engineers!

-1.jpg)