What Is a Differential Pressure Flowmeter?

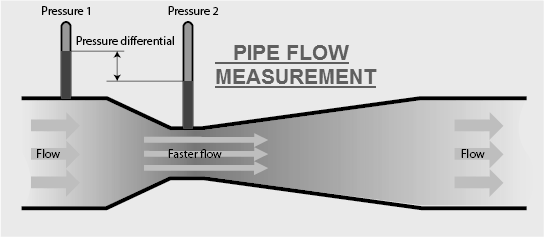

A differential pressure flow meter measures flow by measuring differential pressure. It is based on the principle that there is a certain relationship between the pressure difference and the flow rate generated when the fluid flows through the throttling device.

Also known as a DP flowmeter, it consists of a flow sensor and a pressure/differential pressure transmitter. It can be configured with a variety of restrictive elements, such as orifice plates, venturi tubes, wedges, V-cones, and Annubars. Differential pressure (DP) flowmeters are suitable for water, gas, steam, oil, and other applications.

Featured Differential Pressure Flow Meters

Differential Pressure Flow Meter Working Principle

The working principle of a differential pressure flow meter is based on the Bernoulli and Poisson equations in fluid mechanics. Flow rate is inferred by measuring the pressure difference generated when a fluid flows through a laminar flow device.

First, let’s look at the Bernoulli equation. The Bernoulli equation describes the conservation of energy during fluid flow. It can be expressed as:

P + 0.5ρ v^2 + ρgh = constant.

Where P is the static pressure of the fluid, ρ is the density of the fluid, v is the flow velocity, g is the acceleration due to gravity, and h is the height of the fluid.

During fluid flow, if the flow velocity increases, the static pressure decreases. Conversely, if the flow velocity decreases, the static pressure increases. This is the basic principle of the Bernoulli equation.

Next, let’s look at the structure of a differential pressure flow meter.

A differential pressure flow meter consists of a throttling element, a pressure sampling tube, and a differential pressure transmitter. When fluid flows through the measuring tube, a pressure differential is generated due to the geometry of the pipe and the properties of the fluid.

The pressure sampling tube introduces the high and low pressures in the pipeline to a differential pressure transmitter for measurement. The differential pressure transmitter converts these two pressure values into electrical signals, which are then displayed and recorded by a flow totalizer.

Finally, let’s look at the working principle of a differential pressure flowmeter.

When a fluid flows through the measuring tube, constrictions, bends, or obstructions in the pipeline cause the fluid’s flow rate to change, resulting in a pressure differential.

A differential pressure flowmeter uses the principles of Bernoulli’s equation and Poisson’s equation to calculate the fluid flow rate by measuring the pressure differential in the pipeline. The specific calculation formula is:

Q = K√ δP

Where Q is the fluid flow rate, K is the flowmeter’s calibration factor, and δP is the pressure differential in the pipeline. Using this formula, we can accurately calculate the fluid flow rate.

In short, a differential pressure flowmeter uses the principles of Bernoulli’s equation and Poisson’s equation to calculate the fluid flow rate by measuring the pressure differential in the pipeline.

Read more about: Differential Pressure Flow Meter Technology

Differential Pressure Flow Meter Types

Differential pressure flow meters are classified by structure:

Standard orifice plate, standard nozzle, classic Venturi tube, Venturi nozzle, quarter-circular orifice plate, tapered inlet orifice plate, segmented orifice plate, eccentric orifice plate, wedge-shaped orifice plate, Doyle tube, Roros tube, linear orifice plate, small-diameter orifice plate (with built-in orifice plate), elbow, annular tube, interchangeable orifice plate throttling device, balanced flowmeter, and insertion flowmeter.

Commonly used types include the following:

Differential Pressure Flow Meter Advantages and Disadvantages

Differential pressure flowmeters are one of the most widely used flowmeter types in the industrial field. Their advantages and disadvantages are closely related to their structure and operating principle.

Advantages

- The structure is simple and the cost is low. The manufacturing process is mature, requiring no complex moving parts or electronic components. The cost is relatively low.

- Wide range of applications. They can measure a wide range of fluid types, including liquids, gases, and steam.

- It has strong adaptability to the viscosity, density and other properties of the fluid (as long as a stable differential pressure can be formed).

- The applicable range of pipe diameter is wide. They are particularly advantageous in measuring large-diameter pipes.

- The throttling device is typically made of metal, which is resistant to high temperatures, high pressures, and corrosion. They are suitable for harsh operating conditions (such as high-temperature steam and corrosive liquids).

Disadvantages

- Fluid Reynolds number, pressure, and temperature changes can affect the relationship between differential pressure and flow rate, requiring corresponding corrections.

- Pulsating flow can increase measurement errors.

- Sufficiently long straight pipe sections are required before and after the throttling device. Typically, this should be 10-50 DN upstream and 5-10 DN downstream.

- Pipe roughness and eccentric installation of the throttling device can also cause errors.

- When fluid flows through a throttling device, pressure loss can be as high as 30%-80% of the measured differential pressure.

- The throttling hole of the throttling device is easily blocked or worn by particles and impurities in the fluid, resulting in distortion of the differential pressure measurement. Regular cleaning and maintenance are necessary.

More Flow Measurement Solutions

Among the many flow measurement instruments, differential pressure flowmeters account for approximately 70% of key applications.

They are widely used in industries such as petroleum, chemical engineering, metallurgy, power generation, and light industry. In the petrochemical industry, they precisely control the delivery of various raw materials and products. In the power industry, they rigorously monitor the flow of media such as steam and water.

Flow measurement accuracy is directly related to production efficiency, product quality, and energy efficiency. Therefore, it is crucial to select the appropriate differential pressure flowmeter based on the actual operating conditions.

Need help? Contact us now.

We will offer you suitable Flow Measurement Solutions!

-1.jpg)