There are a few areas where industrial flow measurement is important, such as residential waste. Among the various flow meter types available, inductive flow meters, particularly magnetic inductive flow meters, are widely preferred in applications involving conductive liquids. Inductive flow meters also find homes in many industrial control processes, including chemical/pharma, food and beverage, and pulp and paper.

These flow meters provide highly accurate, reliable measurements, making them indispensable in many industries such as water treatment, food and beverage, chemical processing, and more.

Magnetic Inductive Flow Meter: How it is different from other flow meters

An inductive flow meter measures the flow of liquids by using the principle of electromagnetic induction.

The key distinction between inductive flow meters and other types (such as mechanical or ultrasonic flow meters) is that they do not have moving parts, making them less prone to wear and tear and providing a longer service life.

Operational Principle

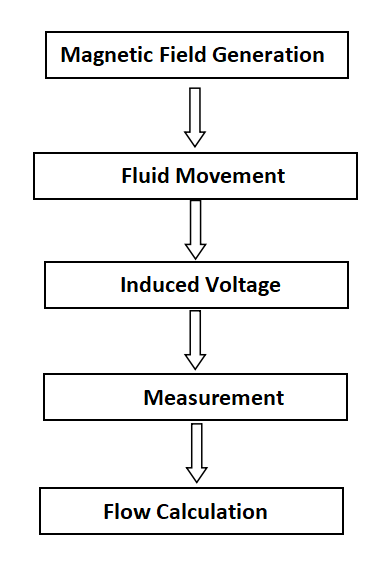

The magnetic inductive flow meter operates according to the induction principle, i.e. a direct voltage is generated through the movement of a conductor in a magnetic field.

The measurement principle is based on the work of English physicist Michael Faraday and his eponymous law of induction. According to the law of induction, a force acts on electric charge carriers when they move through a magnetic field so that a voltage is induced transversely to the direction of movement. This effect is also known as the “Hall effect”.

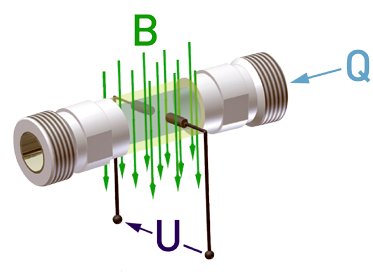

The measuring pipe of the flow sensor is surrounded by a magnetic field (B). An electrically conductive liquid (Q) flows through the measuring pipe. The positive and negative charge carriers are deflected in the opposite direction. A voltage perpendicular to the magnetic field is produced, which is picked up by the two electrodes. The induced voltage is proportional to the average flow velocity of the liquid.

A parasitic effect is that in addition to the useful signal, an interference voltage occurs due to electrochemical disturbances, which is referred to as electrode chemistry. This effect can be compensated for with the use of a clocked constant field. This means that the magnetic field of the coil is continuously reversed so that the useful signal constantly changes its polarity but the interference signal does not. In this way, useful signals and disturbances can be distinguished from each other and the measuring accuracy can be improved.

Read more about Magnetic Flowmeter Technology

Benefits of Inductive flow meters

Types of Liquids Appropriate for Inductive Flow Meters

Inductive flow meters are primarily designed for conductive liquids. A liquid is considered conductive if it has an electrical conductivity greater than a certain threshold, typically in the range of 5 microsiemens per centimeter (µS/cm) or higher.

Common examples of conductive liquids include water, industrial chemicals, especially acids, salts, and solutions, and Beverages like juices, milk, and alcoholic drinks. Moreover, slurries that contain solids suspended in liquids (e.g., in mining or paper mills) are often conductive and can be accurately measured using inductive flow meters.

- BTU Meter Optimizes Energy Efficiency of Hot and Cold Water Systems

- Pulse Output Flow Meters for Better Water Flow Measurement

- Slurry & Sludge Flow Measurement

- High-Pressure Flow Meters

- Cooling Water Flow Measurement

- Flow Meters for Domestic Water-Potable Water-Drinking Water

- Wastewater flow meter

- Water Flow Meter Types

Applications of Magnetic Inductive Flow Meters

- Waste Water Treatment: Magnetic inductive flow meters are used extensively to measure the flow of water through pipes, filtration systems, and distribution networks.

- Chemical Processing: Magnetic inductive flow meters can deal with a wide range of chemical solutions, including acids, alkalis, and solvents. They are used in reactors, mixing systems, and other process equipment.

- Food and Beverage industry: Magnetic inductive flow meters are used to measure liquids such as milk, juices, syrups, and sauces. These meters are often preferred because they provide a hygienic, non-contact measurement and do not contaminate the product.

- Pulp and Paper: The pulp and paper industry often deals with highly abrasive slurries. Magnetic inductive flow meters are used to measure the flow of pulp, water, and chemicals used in the production process.

- Oil and Gas: While inductive flow meters are not fit for pure hydrocarbons, they are ideal for measuring the flow of conductive liquids in certain oil and gas applications. For example, when measuring the flow of water used in oil extraction or processing, magnetic inductive flow meters can provide accurate readings.

Factors to Consider When Selecting an Inductive Flow Meter

- Conductivity of the Liquid

- Pipe Size and Installation: Inductive flow meters are typically used in larger pipe sizes, but it is essential to select a meter that fits the specific dimensions of your pipeline.

- Temperature and Pressure

- Accuracy and Range

- Material Compatibility

- Signal output

By understanding the working principle, advantages, and applications of inductive flow meters, industries can make an informed decision when selecting the right flow measurement technology for their specific needs. With their precision and low maintenance requirements, magnetic inductive flow meters will continue to be an essential tool in optimizing fluid management across various industries.

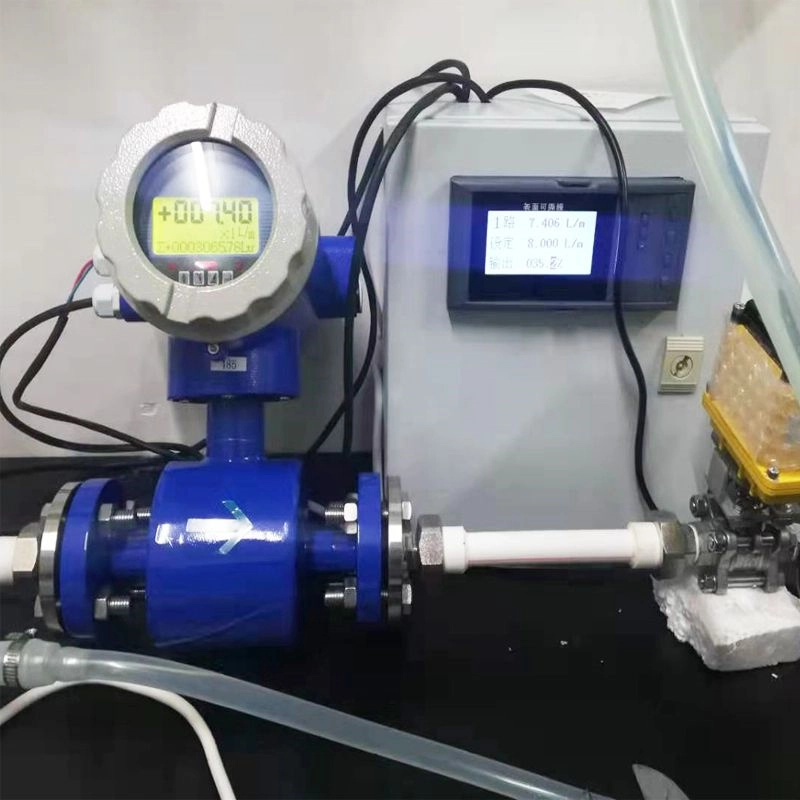

Magnetic inductive flow meters are one of the most popular flow meter solutions provided by Sino-Inst. We have a distinct, reliable set of magnetic flow meters to accommodate Customer’s demand in China as well as in foreign market.

-1.jpg)