Level measurement is the process of measuring the level of a liquid or solid material inside a tank, silo, container or reservoir. Measurement is calculated from the distance between the liquid or solid material surface and a predetermined reference point.

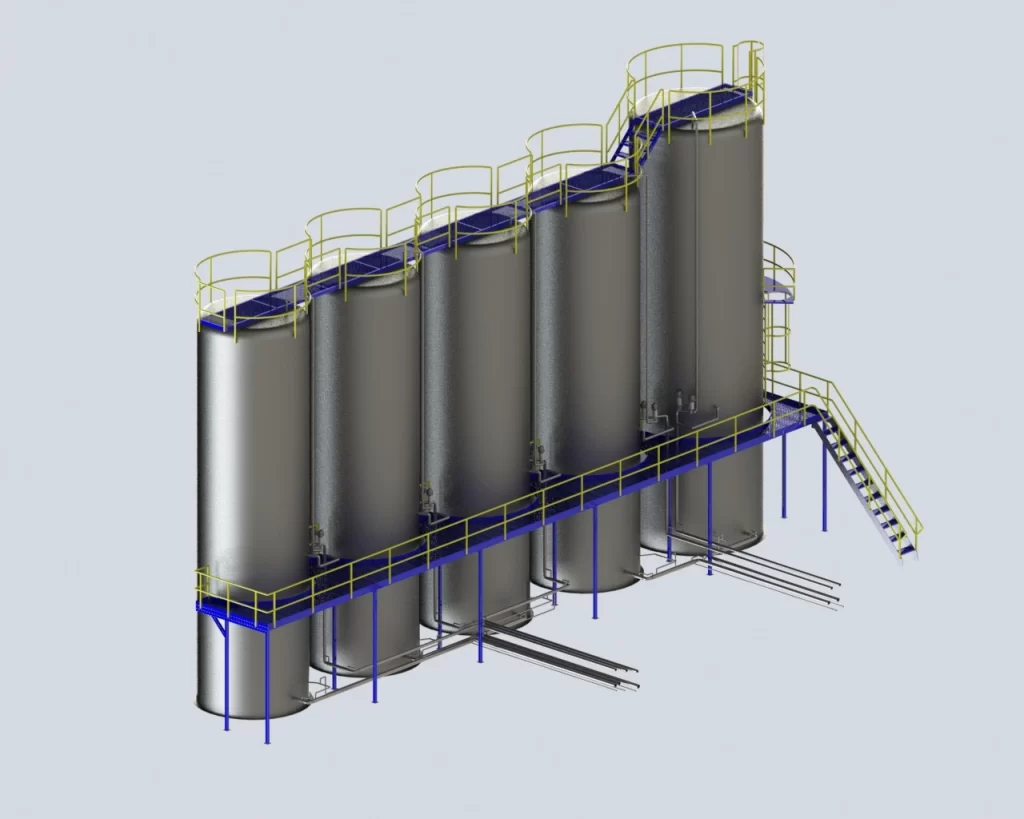

Among the several applications of level measurement, the bin level measurement system plays an important role in bulk material handling industries such as cement, food processing, agriculture, and mining.

What is the difference between level measurement and level monitoring?

While the terms “level monitoring” and “level measurement” are often used interchangeably, there are subtle differences in their meaning.

Level Measurement: The purpose of bulk material level measurement is to ascertain the distance from a reference point to the surface of the bulk material in the vessel. It is used to obtain a numerical value that can also be turned into a measurement of volume based on the known geometry of the vessel.

Level Monitoring: The purpose of bulk material level monitoring is to track and sometimes control the level of bulk material within a vessel. It may not provide a measurement function, but it allows for trend observation and some degree of level control if paired with a relay that can operate start/stop fill functions. They can also provide a simple alarm via the switch point when a certain level has been reached.

Level Measurement System Types

Importance of Level Measurement Systems in Business

- Process Optimization

- Safety

- Regulatory Compliance

- Prevents overflows and material wastage

- Maintains consistent feed in process lines

- Inventory Control: Ensures accurate inventory records

- Enhances worker safety by reducing the need for manual inspection

- Automation Integration: Helps automate bin replenishment and emptying schedules

Bin Level Measurement System: Specialized for Mass Solids

What’s the consideration behind Bin Level Measuring System:

First, the unstable material supply leads to large fluctuations in the material inventory in the silo;

Second, the production demand changes rapidly, and the timeliness of material supply is required to be high;

Third, the inaccuracy and lag of manual inspection make it difficult to detect and deal with material level problems in time.

Kinds of Bin Level Measurement Systems

1. Radar-Based Bin Level Systems

Radar systems are a favorite for bin level applications due to their non-contact nature and reliability in dusty conditions.

Ideal for tall silos and materials with irregular surfaces.

Works in extreme temperatures and pressure ranges.

2. Acoustic and Ultrasonic Systems

Ultrasonic systems work well for short to medium-height bins storing dry materials. Some systems use acoustic waves to penetrate through dust clouds and provide accurate readings.

More economical but susceptible to environmental interference.

3. Laser Bin Level Sensors

Laser sensors provide pinpoint accuracy and are great for materials with poor reflectivity. However, dust and vapor may reduce measurement reliability.

Ideal for applications requiring precise volume calculations.

4. Weight and Load Cell-Based Systems

Instead of measuring material height, these systems measure the total weight of the bin. Load cells are placed at the bin’s legs or base.

Offers real-time mass measurement.

Immune to dust and bridging issues.

5. Capacitance and RF Admittance Systems

Suitable for bins with powders and granular materials. These systems are resistant to build-up and can be used in high-temperature environments.

Useful for both point-level and continuous-level detection.

In addition to solid powder level measurement, we at Sino-Inst also provide solid powder flow measurement solutions.

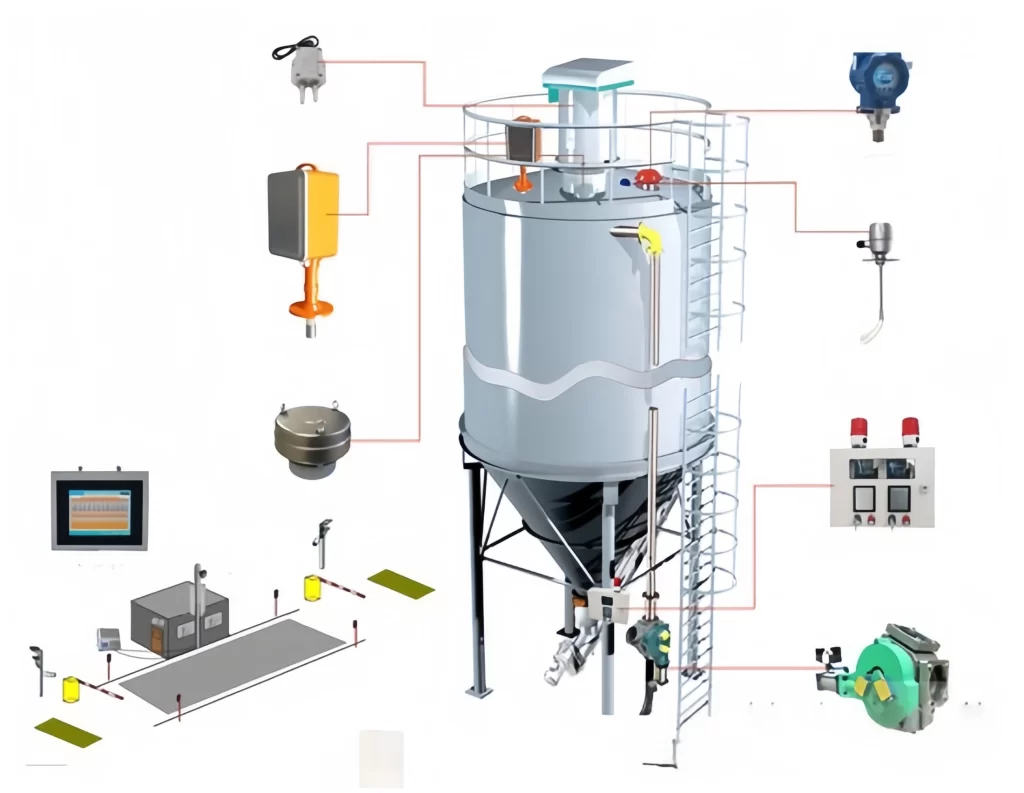

Fundamental Features of Modern Bin Level Measuring Systems

The level measurement system can achieve real-time monitoring and accurate measurement of the material height inside the silo by adopting advanced level detectors and intelligent algorithms. Whether it is solid particles, powders or liquids, the level measurement system can flexibly select the appropriate detection method according to the characteristics of the material and the structure of the silo to ensure the accuracy of the measurement data.

Fundamental Features:

- Digital Readouts

- Remote Monitoring

- Alarming & Notifications

- Robust Construction

- Low Maintenance

Selecting the Right Level Measurement System

- Type of Material

Is the material liquid, powder, granule, or slurry? Sticky, dusty, or corrosive materials require specialized sensors. - Container Size and Shape

Tall silos may require guided wave radar, while small bins may use ultrasonic or capacitance sensors. - Environmental Conditions

Temperature, pressure, humidity, and vibration can affect sensor performance. - Measurement Type

Do you need continuous measurement or simple point detection? The application will dictate the sensor technology. - Accuracy Requirements

Processes requiring tight inventory control benefit from radar, laser, or weight-based systems. - Integration Needs

Make sure the sensor has compatible communication protocols (e.g., 4-20mA, Modbus, HART).

More Level Measurement Solutions

- An Out-and-Out Guide To Different Types Of Level Transmitters

- Bitumen And Asphalt Level Meters: Let’s Learn More About Them

- Bin Level Indicators and Controllers

- The Next Level Of Flow Measurement: Here Come Non-Intrusive Flow Meters

- Dry Materials-Bulk Solids-Powder Level Sensors Guide

- Role of Hydrostatic Level Transmitters In Well Water Level Monitoring Process

- Different Diesel Level Sensors for Diesel Tank Level Measurement

- Tank Level Measurement with Pressure Transmitters/DP Transmitters

- Hydrostatic Level Measurement-Liquid Level Measurement with Pressure Sensors

A reliable level measurement system is vital to the fine-textured operation of industrial facilities, helping prevent costly errors, improve safety, and maintain optimal inventory. When it comes to handling bulk solids, a dedicated bin level measuring system ensures accurate monitoring of bin contents, reducing the risk of overflow, shortage, or human error.

By understanding the characteristics, advantages, and limitations of different level sensors, you can make informed decisions that drive efficiency, safety, and profitability across your operation.

Sino-Inst is always available at its customer service, helping them in finding the best Level measurement solutions. If you need level measurement, please feel free to contact our sales engineers!

-1.jpg)