Flow meter accuracy directly impacts a manufacturer’s profitability and operational integrity. A flow meter is more than just a process instrument; it’s a critical tool. Understanding flow meter accuracy and related parameters is crucial for process control, quality assurance, and cost-effectiveness across various industries.

What Is Flow Meter Accuracy?

Flow meter accuracy is the degree of closeness between the measured value and the true value, typically expressed as a percentage. For example, an ultrasonic flow meter with ±1% reading accuracy that reads 1 GPM will actually flow between 0.9 GPM and 1.1 GPM.

Flow meter accuracy is typically used to quantify the reliability and error of measurement results. It is a combination of precision and accuracy. Accuracy reflects the degree of deviation of the measured value from the true value; the smaller the error, the higher the accuracy.

Accuracy-Related Parameters

When discussing flow meter accuracy, many terms are often confused or even incorrectly used. These terms, in particular, include accuracy, repeatability, and resolution. Let’s take a closer look at these terms and explain their respective meanings.

| Related parameters | Accuracy | Repeatability | Resolution |

| Definition | How close the flow meter reading is to the actual true flow rate. | When the true flow is 100 GPM, a meter reads 100 GPM, the meter is highly accurate. | The smallest change in flow that a flow meter can detect. |

| Example | When the actual flow is 100 GPM, the flow meter will always read 103 GPM. This reading is highly repeatable, but not accurate. | The consistency of the results occurs when the same parameter is measured multiple times under the same conditions. | A flow meter with a resolution of 0.1 PSI can measure a change of 0.1 PSI, but it cannot measure a change of 0.05 PSI. |

| Impact | Precision affects measurement accuracy. | A flow meter must be repeatable to remain accurate. | Resolution directly affects measurement sensitivity and data acquisition capabilities. |

| Representation | Percent of Reading (%RD).Percent of Full Scale (%FS). | Usually expressed as ± percent. | When the true flow is 100 GPM, a meter reads 100 GPM,the meter is highly accurate. |

What Is a Flow Meter’s Accuracy Grade?

Actual accuracy may be affected by fluid properties, installation conditions, and environmental interference. It may be lower than the theoretical value. Understanding the flow meter’s accuracy grade is helpful when selecting a flow meter.

The accuracy grade of a flow meter indicates its maximum allowable measurement error as a percentage of the full range. For example, a grade of 1.0 means the error does not exceed ±1% of the full range. The accuracy grade is the core indicator for measuring the measurement accuracy of a flow meter. Therefore, the lower the grade, the higher the accuracy and the smaller the error.

The formula for calculating accuracy grade is: Relative percentage error = (Measured value – Standard value) / (Upper range limit – Lower range limit) × 100%. Common grades for industrial instruments in my country include 0.1, 0.2, 0.5, 1.0, 1.5, 2.5, and 5.0.

They can be categorized by application as follows:

- Standard instruments: Grade 1 (0.005, 0.02, 0.05), Grade 2 (0.1, 0.2, 0.35, 0.5).

- Industrial instruments: Grades 1.0, 1.5, 2.5, and 4.0.

- Scientific laboratory instruments: Accuracy ≥ 0.05.

What Is Flow Meter Repeatability?

Flow meter repeatability refers to the ability of a flow meter to produce consistent results after measuring the same flow rate multiple times under the same conditions. Essentially, it measures the dispersion and reliability of measurement results. It indicates that even if the meter readings consistently deviate from the true value, their “grouping” is very close.

Repeatability directly impacts flow meter reliability; high repeatability ensures stable data. However, a highly repeatable instrument doesn’t necessarily guarantee accuracy. For example, a temperature sensor might consistently deviate by 5 degrees. However, if this deviation persists, calibration is necessary. Considering the degree of deviation from actual temperature, a highly accurate instrument can replace a highly repeatable one.

Accuracy refers to how close a measurement is to the true value. But repeatability reflects the consistency of multiple measurements and does not involve the true value. For example, a flow meter may have low accuracy due to systematic errors but still have good repeatability.

What Is Flow Meter Resolution?

Resolution is the smallest flow increment a flow meter can detect and record. Essentially, it’s the smallest measurement step size. It measures the flow meter’s ability to discern flow. In addition , Resolution is a separate specification from accuracy. A flow meter can have high accuracy but poor resolution, and vice versa.

If a scale only displays whole numbers, its resolution is 1 pound. If a scale displays tenths of a pound, its resolution would be 0.1 pound. In a flow meter, this refers to the smallest change in flow that can be sensed by the sensor or display inside the flow meter.

What Is Flow Meter Sensitivity?

Sensitivity is the ratio of the change in the meter’s output to the change in its input. A flow meter’s sensitivity reflects its ability to respond to small changes. A flow meter with high sensitivity can detect even smaller changes in flow rate. This allows for more accurate measurements, especially at low flow rates.

Sensitivity is influenced by the meter’s resolution and its minimum measurement range. Different flow meter technologies have different sensitivities. For example, thermal mass flow meters excel at measuring low gas flows, but their sensitivity decreases at higher flow rates. As seen with thermal flow meters, the relationship between the measurement characteristics and flow rate can be nonlinear. This results in reduced sensitivity at higher flow rates.

The resolution also depends on the sensitivity of the flow meter. A high sensitivity means that the flow meter can detect smaller flow changes.

What Is a Flow Meter’s Full-Scale Accuracy?

A flow meter’s full-scale accuracy refers to the measurement error within the instrument’s full-scale range. Is is abbreviated as FS. It’s usually expressed as a percentage of the full-scale value. For example, a full-scale accuracy of ±1% means the measurement error is within ±1% of the full-scale value.

Example: Consider a flow meter with a full-scale range of 0 to 1000 L/min and an accuracy of ±1% FS. Regardless of flow rate, the permissible error is always ±10 L/min (1% of 1000 L/min).

At a flow rate of 1000 L/min, the measured value is between 990 L/min and 1010 L/min.

At a flow rate of 100 L/min, the measured value is between 90 L/min and 110 L/min.

Accuracy class isn’t the only way to measure flow meter accuracy. For example, the percentage of full scale (often abbreviated as %FS) is a common way to express accuracy for many flow meters. Flow meter accuracy can also be expressed as follows:

- Accuracy expressed as a percentage of full scale (FS) provides a constant error value.

- Accuracy expressed as a percentage of reading (Rd) provides a constant percentage of the actual flow rate.

- Calibrated span (abbreviated as %CS)

- Upper range limit (abbreviated as %URL)

- Percent of measured value (%MV)

Which Flow Meter Offers the Highest Accuracy?

The most accurate flow meter is typically a Coriolis flow meter. It directly measures mass flow with an accuracy of ±0.1% to ±0.5%. However, it is expensive, bulky, and sensitive to vibration, making it unsuitable for most applications.

Other high-precision flow meters include positive displacement flow meters, electromagnetic flow meters, and ultrasonic flow meters. These offer many features not available with rotameters. Since they have no moving parts subject to wear, they require less maintenance. However, they are best suited for specific applications and fluids.

You can choose the right flow meter based on your application needs. Simple rotameters can also provide adequate accuracy. They are generally less expensive than electromagnetic and ultrasonic flow meters.

Comparing the Accuracy of Different Flow Meters

The accuracy of different flow meters varies depending on the measurement principle and application scenario. To learn more about flow meter technology types and how they work, please visit our Sino-inst article on “11 Flow Meter Types and Their Advantages and Disadvantages“.

| Flow meter Type | Accuracy Range |

| Coriolis Flow Meters | 0.1%–0.5% |

| Positive Displacement Flow Meters | 0.2%–2.5% |

| Magnetic Flow Meters | 0.5%–2% |

| Thermal Mass Flow Meters | 1%–2% |

| Ultrasonic Flow Meters | 0.7%–1% |

| Vortex Flow Meters | 1%–2.5% |

| Paddle Wheel Meters | 1.5%–3% |

| Variable Area Flow Meters(Rotameter) | 1.5%–5% |

| Differential Pressure Flow Meter | 3%–5% |

How Do You Measure Flow Meter Accuracy?

You can measure flow meter accuracy through a calibration process. Under controlled conditions, the flow meter’s reading is compared to a known, more accurate reference flow meter. Accuracy is expressed as a percentage of full scale (FS) or actual reading (AR). The correct accuracy also includes the valid operating range. This is because accuracy can vary significantly at high and low flow rates.

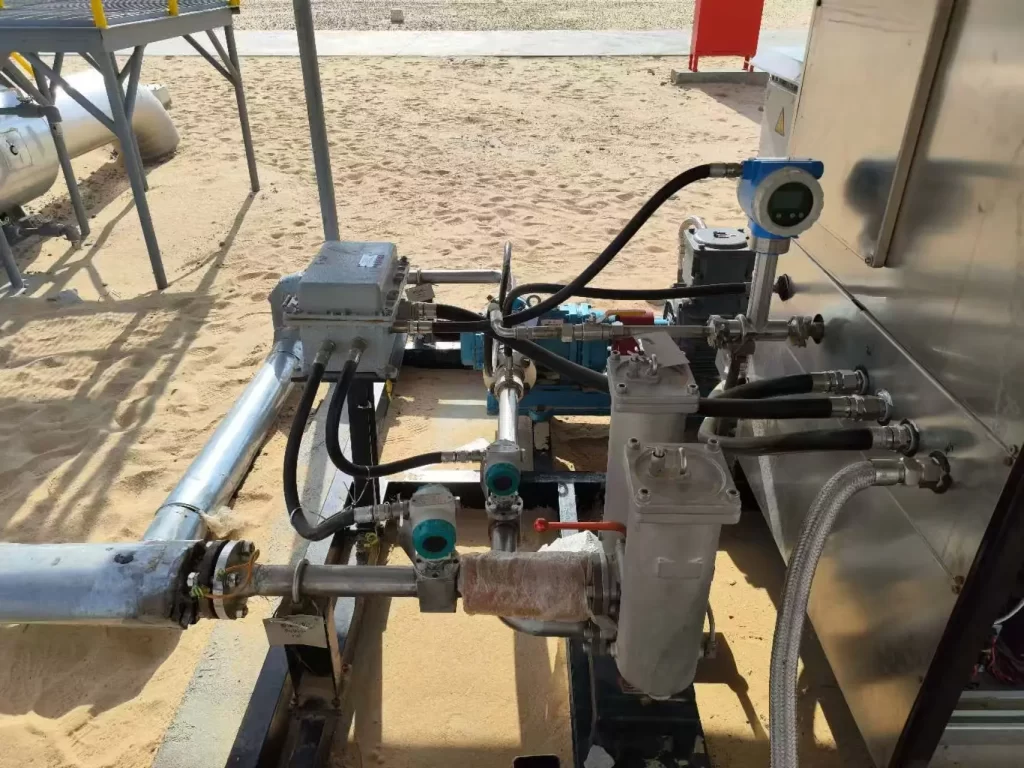

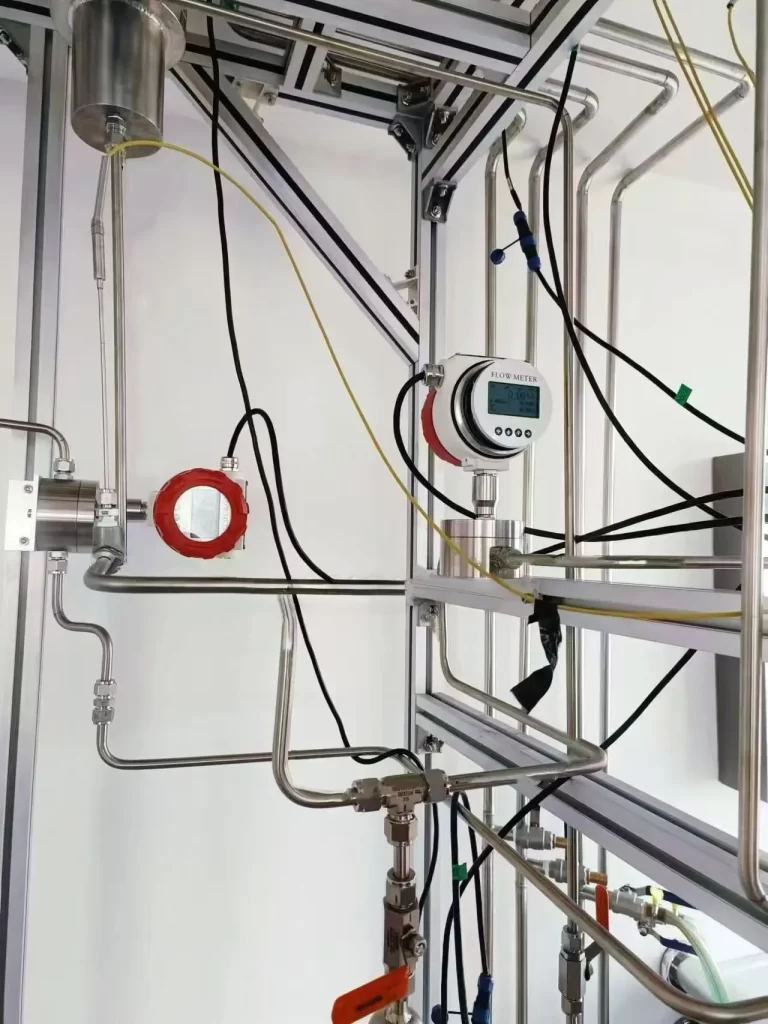

The calibration process requires a calibration stand. This includes adjustable valves and data collection methods.

- You install a reference flow meter with higher accuracy than the flow meter under test in the test loop.

- Flow is passed through both the reference flow meter and the flow meter under test simultaneously.

- The readings from the flow meter under test are then compared to those from the reference flow meter.

- Finally, calculations are performed to determine how closely the flow meter’s readings at various points within its operating range match the reference values.

Factors Affecting Flow Meter Accuracy

Flow meter accuracy is primarily affected by factors such as fluid characteristics, installation conditions, and environmental factors. To maintain accuracy, the flow meter must be suitable for the fluid. Also, ensure adequate straight pipe length and regular calibration.

- High-viscosity fluids increase internal friction and pressure loss. Low-viscosity fluids may cause leakage errors.

- Density and temperature. Density changes affect the calibration of volumetric flow meters. Temperature fluctuations can alter fluid volume, pipe dimensions, and material elastic modulus.

- Bubbles or impurities. Bubbles or particles in the fluid can interfere with sensor signals, such as the Doppler effect in ultrasonic flow meters. This can cause idling or blockage, resulting in errors of over 15%.

- Straight pipe length. Sufficient straight pipe length is required before and after the flow meter. Otherwise, flow field distortion will lead to uneven velocity distribution, affecting the accuracy of vortex or orifice flow meters.

- Temperature and pressure. Ambient temperature fluctuations can cause electronic component degradation or material deformation. Pressure fluctuations can change fluid density and pipe stress, requiring compensation mechanisms.

- Vibration and electromagnetic interference. Mechanical vibrations can couple to the flow meter sensor. Strong electromagnetic fields can interfere with signal transmission, causing reading drift.

How Can I Improve Flow Meter Accuracy?

If you want to improve flow meter accuracy, you need to consider multiple aspects, including selection, installation, and maintenance.

Choosing the Right Flow Meter

Many factors in your application can affect flow meter accuracy. You need to select the appropriate flow meter type based on your specific application needs. For example, a vortex flow meter is recommended for measuring high-temperature, high-pressure steam; an ultrasonic flow meter is recommended for large-diameter pipes. If your selected flow meter requires full pipes and no bubbles to function properly, but you’re running a half-filled pipe and bubbles and foam appear in the pipe, it will not achieve its designed accuracy and may even fail to function at all.

Proper flow meter installation

When installing a flow meter, you should ensure there is sufficient straight pipe length before and after the meter. This reduces eddy currents and pipe roughness. Additionally, the installation location should be away from sources of disturbance. Such as valves and elbows, and should be coaxial with the sensor. If you do not meet these requirements, accuracy may be severely affected.

Maintenance and Calibration

Regular maintenance is also crucial to maintaining optimal flow meter performance. Regularly removing deposits prevents corrosion and scaling. Some flow meter technologies require more frequent calibration than others. Other flow meters may not require any calibration at all during their lifetime. However, you should calibrate your flow meter at least annually, and high-precision equipment every six months.

More Flow Measurement Solutions

Accuracy is a key parameter to consider when selecting a flow meter. Flow meter accuracy directly impacts industrial production efficiency, product quality control, and operational safety. However, many other factors determine which flow meter is right for your application. Certain flow meter technologies may not be suitable for certain applications, while others may be too complex. Therefore, it is crucial to understand flow meter accuracy and its related parameters before purchasing a flow meter.

At Sion-inst, we have a professional engineering team. We are ready to provide free assistance at any time to help you find the best solution for your application. If you have any questions about flow meter accuracy, please call us today.

-1.jpg)