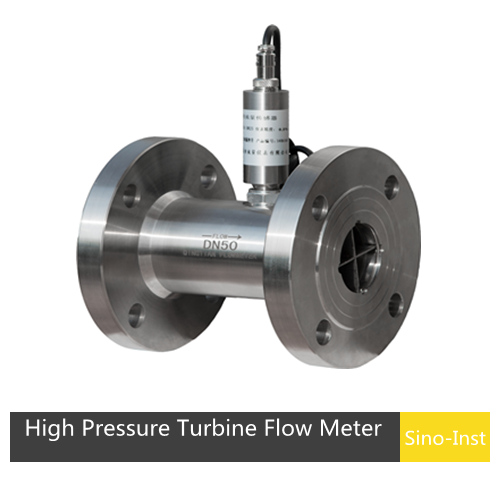

PD flow meter-spiral double rotor is the latest generation of positive displacement flow meter, a precision instrument used for the measurement and control of liquid flow in pipelines. It adopts a pair of special toothed spiral rotors. No pulsation, extremely low noise, high precision, high reliability, large flow rate, and strong environmental adaptability.

The flow meter is equipped with a pointer and a wheel counter, which can indicate the accumulated amount of flow. The counter with a zero device can also indicate a single accumulation. It can also output electrical pulse signals and 4-20mA analog output.

Features

PD Flow Meter-Spiral Double Rotor Technical Parameters

1. Main component materials and nominal pressure

| Model | Shell, front cover, back cover | Cover plate | spiral rotor | shaft | Shaft sleeve | Nominal pressure (MPa) |

| LLT-E | cast steel | cast iron | Cast iron, aluminum alloy, stainless steel | Stainless steel | Graphite, rolling bearings | Below DN100-4.0 |

| DN150 and above-2.5 | ||||||

| LLT-B、C | Stainless steel | Stainless steel | Stainless steel | 1.6, 2.0, 2.5 | ||

| LLT-S | Double type flow meter; specifications are DN80, DN100, DN150; nominal pressure 6.3MPa, DN200 nominal pressure 4.0MPa | |||||

| Remarks: | LLT-C material is OCr18Ni12Mo2Ti; LLT-B material is OCr18Ni9Ti; special design can be made for special requirements. | |||||

| Diameter | DN25mm~DN350mm |

| Flow range | 2 ~ 1000 m³/h |

| Accuracy level | ±0.5%, ±0.2% |

| Display method | Mechanical pointer type, LCD digital type |

| Connection method | Flange, thread, clamp |

| Signal output | Pulse signal, 4-20mA signal, RS485 communication, HART protocol |

| Working power supply | 3.6V lithium battery, DC12V, DC24V |

| Electrical Interface | Internal thread M20*1.5 |

| Explosion-proof level | Ex db IIC T6 Gb (LCD digital model) |

| Protection level | IP66 |

- Accuracy level: 0.5 level, 0.2 level

- Repeatability error: The repeatability error of the flow meter does not exceed 1/3 of the absolute value of the basic error limit of the flow meter.

- Operating medium temperature: ambient temperature (-41℃~+50℃); Level 0.5 (-20℃~+80℃) ;Level 0.2(-20℃~+60℃); with high temperature radiator up to 250℃

2. Flow Range

Table 1, accuracy level 0.5

| Model | Diameter | Viscosity mPa.s | ||||||

| 0.3~0.8 | 0.8~2 | 2~15 | 15~400 | 400~1000 | 1000~2000 | 2000~3500 | ||

| Gasoline | Kerosene | Diesel, engine oil | Heavy oil | High viscosity liquid | ||||

| LLT-0252 | 25 | 3~9 | 1.5~10 | 1~10 | 1~10 | 1~8 | 1~8 | 1~6 |

| LLT-0401 | 40 | 3~9 | 1.5~10 | 1~10 | 1~10 | 1~8 | 1~8 | 1~6 |

| LLT-0402 | 7~20 | 3~22 | 2.5~25 | 2.5~25 | 2~18 | 2~18 | 3~12 | |

| LLT-0501 | 50 | 7~20 | 3~22 | 2.5~25 | 2.5~25 | 2~18 | 2~18 | 3~12 |

| LLT-0502 | 9~36 | 4.5~36 | 3.6~36 | 3.6~36 | 2.8~25 | 2.8~25 | 4.5~18 | |

| LLT-0801 | 80 | 9~36 | 4.5~36 | 3.6~36 | 3.6~36 | 2.8~25 | 2.8~25 | 4.5~18 |

| LLT-0802 | 20~80 | 10~80 | 10~100 | 10~100 | 6.5~56 | 6.5~56 | 5~40 | |

| LLT-1001 | 100 | 20~80 | 10~80 | 10~100 | 10~100 | 6.5~56 | 6.5~56 | 5~40 |

| LLT-1002 | 25~100 | 18~100 | 15~150 | 15~150 | 8.5~80 | 8.5~80 | 6.5~55 | |

| LLT-1501 | 150 | 25~100 | 18~100 | 15~150 | 15~150 | 8.5~80 | 8.5~80 | 6.5~55 |

| LLT-1502 | 55~225 | 30~250 | 25~250 | 25~250 | 18~150 | 18~150 | 10~100 | |

| LLT-2001 | 200 | 55~225 | 30~250 | 25~250 | 25~250 | 18~150 | 18~150 | 10~100 |

| LLT-2002 | 90~360 | 50~400 | 40~400 | 40~400 | 28~240 | 28~240 | 20~160 | |

| LLT-2501 | 250 | 90~360 | 50~400 | 40~400 | 40~400 | 28~240 | 28~240 | 20~160 |

| LLT-2502 | 130~540 | 65~540 | 60~600 | 60~600 | 42~360 | 42~360 | 30~240 | |

| LLT-3001 | 300 | 130~540 | 65~540 | 60~600 | 60~600 | 42~360 | 42~360 | 30~240 |

| LLT-3002 | 220~800 | 110~900 | 95~950 | 95~950 | 70~600 | 70~600 | 54~450 | |

| LLT-3501 | 350 | 220~800 | 110~900 | 95~950 | 95~950 | 70~600 | 70~600 | 54~450 |

Table 2, accuracy level 0.2

| Model | Diameter | Viscosity mPa.s | ||||||

| 0.3~0.8 | 0.8~2 | 2~15 | 15~400 | 400~1000 | 1000~2000 | 2000~3500 | ||

| Gasoline | Kerosene | Diesel, engine oil | Heavy oil | High viscosity liquid | ||||

| LLT-0252 | 25 | 3.5~8 | 3~10 | 2~10 | 2~10 | 2~8 | 2~8 | 2~6 |

| LLT-0401 | 40 | 3.5~8 | 3~10 | 2~10 | 2~10 | 2~8 | 2~8 | 2~6 |

| LLT-0402 | 8~20 | 5.5~22 | 4.5~22 | 4.5~22 | 4~18 | 4~18 | 3~12 | |

| LLT-0501 | 50 | 8~20 | 5.5~22 | 4.5~22 | 4.5~22 | 4~18 | 4~18 | 3~12 |

| LLT-0502 | 15~36 | 9~36 | 7~36 | 7~36 | 6~25 | 6~25 | 4.5~18 | |

| LLT-0801 | 80 | 15~36 | 9~36 | 7~36 | 7~36 | 6~25 | 6~25 | 4.5~18 |

| LLT-0802 | 30~80 | 20~80 | 15~80 | 15~80 | 14~56 | 14~56 | 10~40 | |

| LLT-1001 | 100 | 30~80 | 20~80 | 15~80 | 15~80 | 14~56 | 14~56 | 10~40 |

| LLT-1002 | 40~100 | 25~100 | 20~120 | 20~120 | 18~72 | 18~72 | 14~55 | |

| LLT-1501 | 150 | 40~100 | 25~100 | 20~120 | 20~120 | 18~72 | 18~72 | 14~55 |

| LLT-1502 | 88~220 | 57~225 | 44~220 | 44~220 | 38~150 | 38~150 | 25~100 | |

| LLT-2001 | 200 | 88~220 | 57~225 | 44~220 | 44~220 | 38~150 | 38~150 | 25~100 |

| LLT-2002 | 150~360 | 90~360 | 72~360 | 72~360 | 50~210 | 50~210 | 40~160 | |

| LLT-2501 | 250 | 150~360 | 90~360 | 72~360 | 72~360 | 50~210 | 50~210 | 40~160 |

| LLT-2502 | 180~540 | 135~540 | 100~540 | 100~540 | 90~360 | 90~360 | 60~240 | |

| LLT-3001 | 300 | 180~540 | 135~540 | 100~540 | 100~540 | 90~360 | 90~360 | 60~240 |

| LLT-3002 | 250~800 | 220~900 | 180~900 | 180~900 | 150~600 | 150~600 | 110~450 | |

| LLT-3501 | 350 | 250~800 | 220~900 | 180~900 | 180~900 | 150~600 | 150~600 | 110~450 |

How does a PD flow meter work?

The PD flow meter is mainly composed of a main body, a pair of spiral rotors, a magnetic coupling, a reduction mechanism, an adjustment gear, a counter and a signaling device.

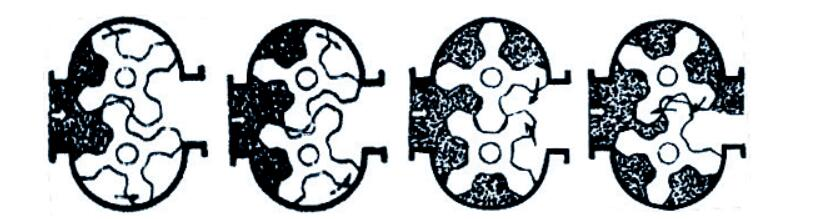

It is a volumetric flowmeter. It uses the hollow part of the spiral rotor (measuring element) and the inner wall of the metering box to form a closed cavity (see the shaded part in the figure) as the measurement chamber.

The small pressure difference between the inlet and outlet drives the rotor to rotate. At the same time, although each rotor receives different rotational moments from the fluid on the same cross-section, the resultant torque of the two rotors receiving rotational moments on all cross-sections is equal.

Therefore, the two rotors each rotate at the same speed and torque, and the displacement is balanced and pulsation-free. The spiral rotor can output 8 times the volume of the cavity per revolution.

Therefore, the rotation speed of the rotor is proportional to the cumulative flow rate of the fluid, and the rotation speed of the rotor is proportional to the instantaneous flow rate of the fluid. The number of revolutions of the rotor is transmitted to the meter counter through the magnetic coupling, which displays the flow rate flowing through the flow meter (flowing through the pipe).

Featured Applications

PD flow meter is a precision instrument used for measurement and control of liquid flow in pipelines.

PD Flow meters can be made of different materials and are widely used in petroleum, chemical industry, light industry, commerce, scientific research and other departments. It is especially suitable for measuring industrial liquids such as crude oil, refined oil, and light hydrocarbons.

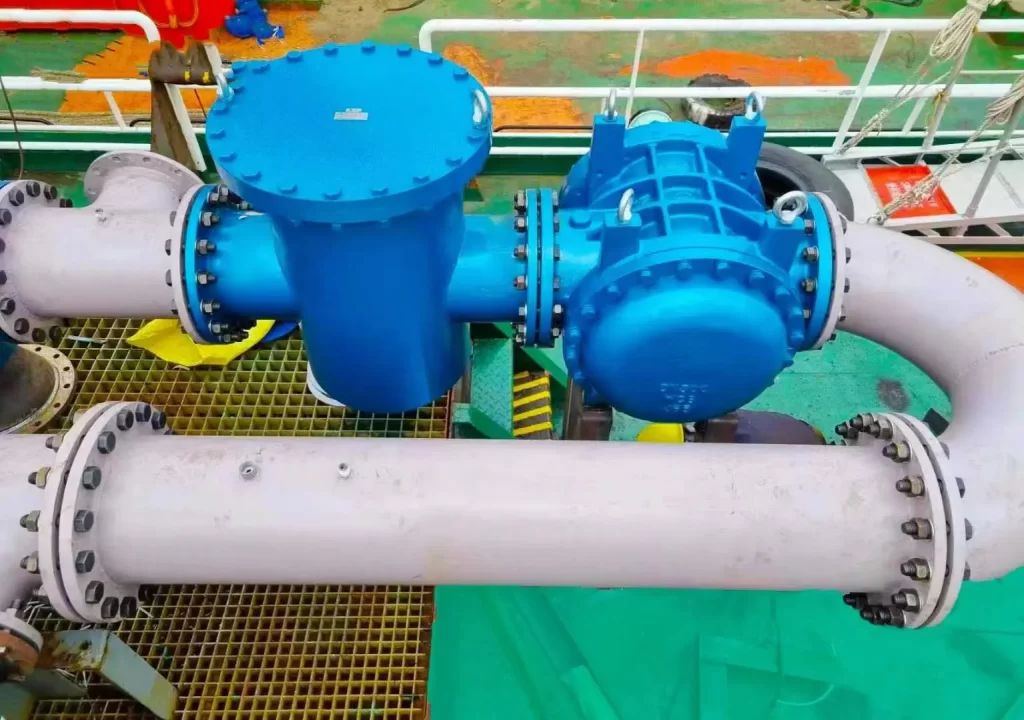

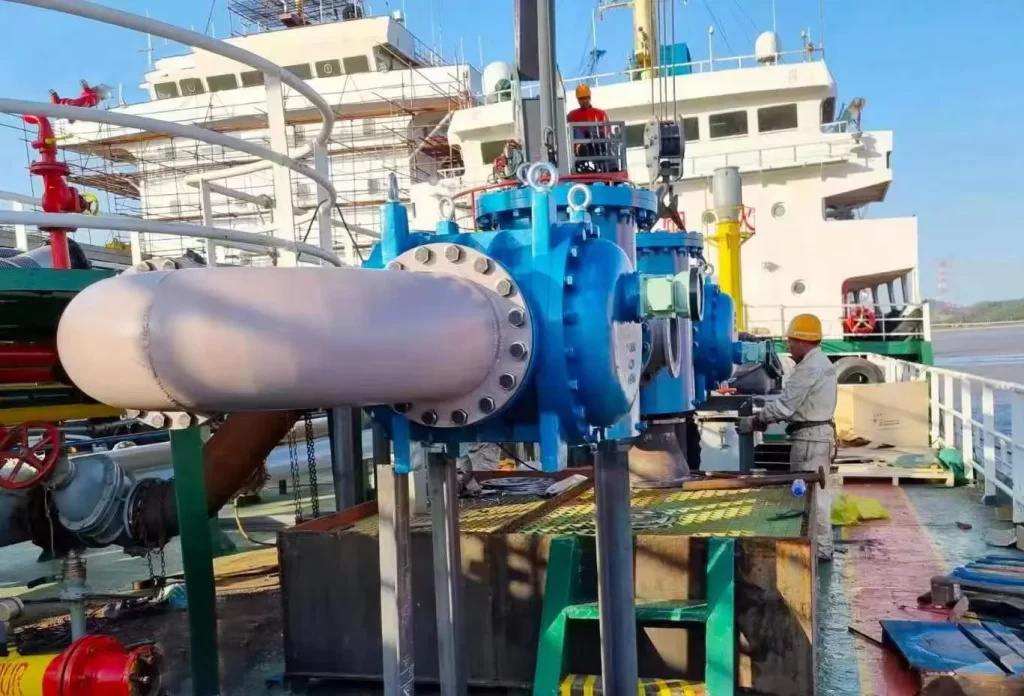

Ship application:

The maximum displacement of the spiral double rotor flowmeter can reach 980 cubic meters/hour (customized), and it is equipped with the same filter to meet the needs of ships.

More Featured liquid flow meters

Ordering Guide

When ordering, please specify the following:

- The name of the medium being measured;

- Flow range (m³/h): minimum, common, maximum

- Medium temperature (℃): minimum, common, maximum

- Medium viscosity (mPa.s): at ()℃

- Fluid pressure (MPa): lowest, commonly used, highest

- medium density;

- Caliber (mm);

- Flange requirements;

- Accuracy requirements;

- Sender configuration requirements:

- Other special requirements.

PD Flow Meter-Spiral Double Rotor is a precision instrument used for the measurement and control of liquid flow in pipelines. It is a new generation of volumetric flowmeter manufactured by our company. Because it uses a pair of special toothed spiral rotors, it is also called “spiral double rotor flowmeter”.

PD Flow Meter-Spiral Double Rotor has the remarkable characteristics of no pulsation, extremely low noise, high precision, high reliability, large flow rate, and strong environmental adaptability. The double-rotor flowmeter launched by Sino-Inst supports the output of electrical pulse signals and flow analog 4~20mA signals for remote instantaneous flow indication or flow adjustment and control. It is widely used in commercial trade measurement and engineering management control in petrochemical, metallurgy, electronics, terminals and other departments.

If you need to purchase PD Flow Meter-Spiral Double Rotor, or have related technical questions, please feel free to contact us.

PD Flow Meter-Spiral Double Rotor for Crude Oil, Heavy Oil, Ship Trade Measurement

PD flow meter-spiral double rotor is the latest generation of positive displacement flow meter, a precision instrument used for the measurement and control of liquid flow in pipelines. It adopts a pair of special toothed spiral rotors. No pulsation, extremely low noise, high precision, high reliability, large flow rate, and strong environmental adaptability.

Product SKU: PD Flow Meter-Spiral Double Rotor

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 1599

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)