Resistance temperature detectors (RTDs) are sensors that use the temperature-dependent resistance of metals to measure temperature. They are widely used in industry and laboratories. They can measure the temperature of liquids, vapors, gases, and solid surfaces within a temperature range of -200°C to 650°C.

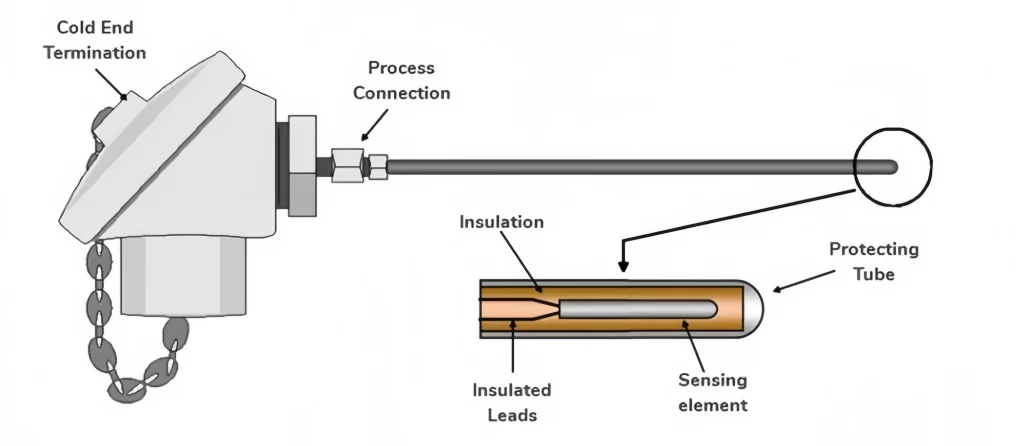

Industrial resistance temperature detectors are categorized by material, including platinum and copper resistors, as well as less commonly used indium and nickel resistors. They generally consist of a temperature-sensing element, transition leads, insulating tubes, protective tubes, junction boxes, and mounting fixtures. Usually used in conjunction with display instruments, recorders, and electronic regulators.

What Is a Resistance Temperature Detector?

A resistance temperature detector (RTD) is a temperature sensor that uses the temperature-dependent resistance of metals or metal oxides to measure temperature. It is also known as an RTD (Resistance Temperature Detector).

The metal used is typically platinum (Pt100), which is stable and readily available. Like thermocouples, it is a commonly used temperature sensor.

We at Sino-Inst mainly produce two major types of assembly thermal industrial thermometers: Pt100, Pt10 platinum thermal resistance and Cu50, Cu100 copper Resistance Temperature Detectors.

Technical Parameters:

| Type | Resistance value | Temperature measurement range | Accuracy level and tolerance (℃) |

| WZP Platinum RTD | Pt100 | -200~500℃ | Grade A: ±(0.15+0.002︱t︱) Grade B: ±(0.30+0.005︱t︱) |

| Pt1000 | -200~650℃ | ||

| WZC Copper RTD | Cu50 | -50~150℃ | ±(0.30+0.006︱t︱) |

| Cu100 |

Note:

︱t︱ is the value of humidity measured by the hygrometer;

Level A accuracy is not suitable for secondary systems, and the thermometer should be calibrated once a year.

Resistance

- Graduation number Pt100 Grade A: R0=100±0.06Ω; Grade B: R0=100±0.12Ω

- Graduation number Pt1000 R0=10±0.012Ω

- Graduation number Cu50 R0=50±0.05Ω

- Graduation number Cu100 R0=100±0.10Ω

Order Guide

PT100 Resistance Temperature Detector accounts for the largest proportion of use. Therefore, what we are mainly discussing here is PT100. If you need other Resistance types, please feel free to contact us!

| W | Temperature instrument | ||||||||||||||

| Z | Thermal resistance | ||||||||||||||

| P | Platinum Resistance | ||||||||||||||

| K | Armored type | The structure form | |||||||||||||

| 1 | Single(can be omitted) | Temperature measuring element option | |||||||||||||

| 2 | Double branch | ||||||||||||||

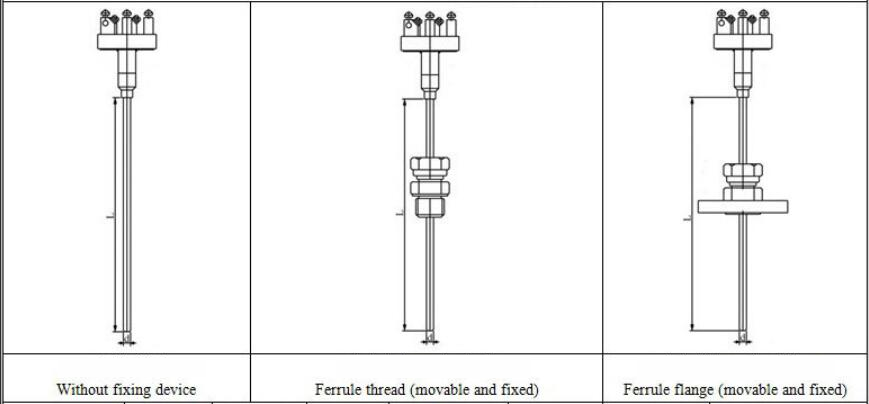

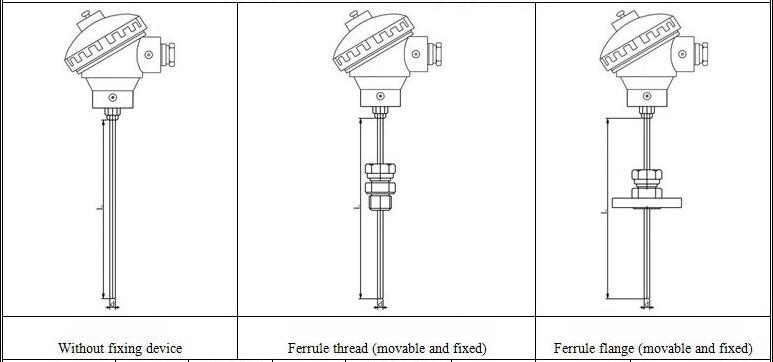

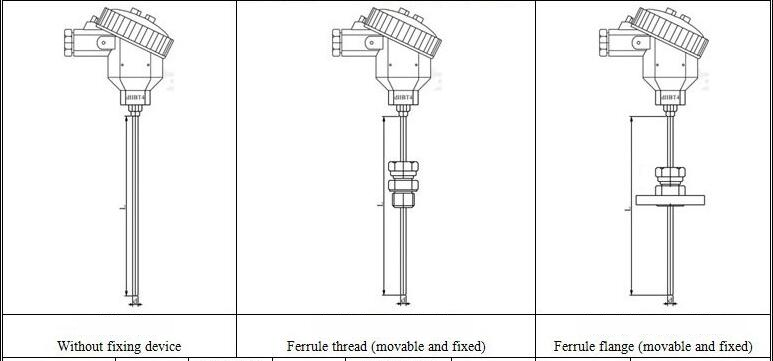

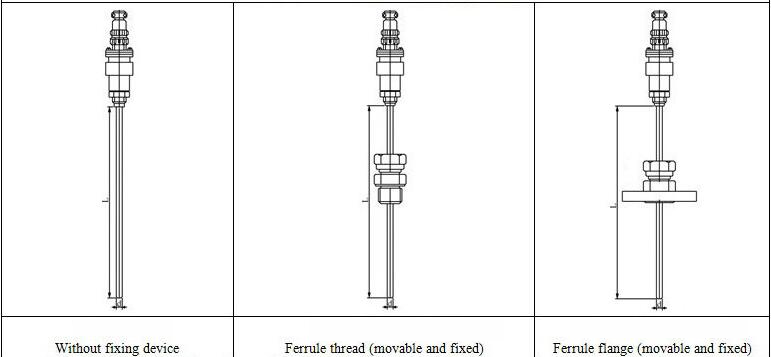

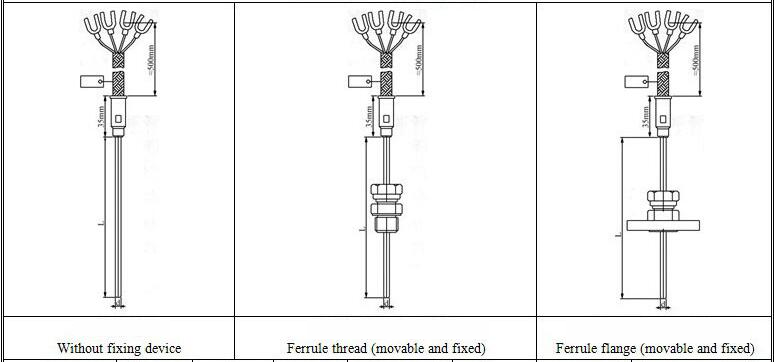

| 1 | No fixed device | Install fixed form | |||||||||||||

| 2 | Fixed ferrule thread | ||||||||||||||

| 3 | Movable ferrule thread | ||||||||||||||

| 4 | Fixed ferrule flange | ||||||||||||||

| 5 | Movable ferrule flange | ||||||||||||||

| 0 | Simple type | The free end of the form(outlet) | |||||||||||||

| 3 | Waterproof type | ||||||||||||||

| 4 | Explosion proof type | ||||||||||||||

| 6 | Socket type | ||||||||||||||

| 7 | With connecting wire | ||||||||||||||

| 3 | φ3mm | Diameter of sensor | |||||||||||||

| 4 | φ4mm | ||||||||||||||

| 5 | φ5mm | ||||||||||||||

| 6 | φ6mm | ||||||||||||||

| 8 | φ8mm | ||||||||||||||

| S | The introduction of elements | ||||||||||||||

| A | Design of serial number | ||||||||||||||

| W Z P K — 2 3 6 S A (example) | |||||||||||||||

Our thermal resistors can also be used with Thermowells.

Industrial Resistance Temperature Detector Types

| Model | Resistance value | Measuring range(℃) | Accuracy level | Thermal response time (T0.5S) | Diameter (mm) | Length (mm) | Installing fixing device |

| WZPK-103SA | PT100 | -200~+420℃ | A or B level | ≤3 | φ3 | Single length: 100 200 250 300 400 500 750 1000 Double branch length: 100 200 250 300 400 500 Note:Special specifications can be customized | Without Fixing device |

| WZPK-104SA | ≤5 | φ4 | |||||

| WZPK-105SA | ≤8 | φ5 | |||||

| WZPK-106SA | ≤12 | φ6 | |||||

| WZPK2-105S | ≤8 | φ5 | |||||

| WZPK2-106S | ≤12 | φ6 | |||||

| WZPK-203SA | ≤3 | φ3 | Fixed ferrule thread | ||||

| WZPK-204SA | ≤5 | φ4 | |||||

| WZPK-205SA | ≤8 | φ5 | |||||

| WZPK-206SA | ≤12 | φ6 | |||||

| WZPK2-205S | ≤8 | φ5 | |||||

| WZPK2-206S | ≤12 | φ6 | |||||

| WZPK-303SA | ≤3 | φ3 | Movable ferrule thread | ||||

| WZPK-304SA | ≤5 | φ4 | |||||

| WZPK-305SA | ≤8 | φ5 | |||||

| WZPK-306SA | ≤12 | φ6 | |||||

| WZPK2-305S | ≤8 | φ5 | |||||

| WZPK2-306S | ≤12 | φ6 | |||||

| WZPK-403SA | ≤3 | φ3 | Fixed ferrule flange | ||||

| WZPK-404SA | ≤5 | φ4 | |||||

| WZPK-405SA | ≤8 | φ5 | |||||

| WZPK-406SA | ≤12 | φ6 | |||||

| WZPK2-405S | ≤8 | φ5 | |||||

| WZPK2-406S | ≤12 | φ6 | |||||

| WZPK-503SA | ≤3 | φ3 | Movable ferrule flange | ||||

| WZPK-504SA | ≤5 | φ4 | |||||

| WZPK-505SA | ≤8 | φ5 | |||||

| WZPK-506SA | ≤12 | φ6 | |||||

| WZPK2-505S | ≤8 | φ5 | |||||

| WZPK2-506S | ≤12 | φ6 |

| Model | Resistance value | Measuring range (℃) | Accuracy level | Thermal response time (T0.5S) | Diameter(mm) | Length(mm) | Installing fixing deyice |

| WZPK-133S | Pt100 | -200~+420℃ | A or B | ≤3 | φ3 | Single length: 100 200 250 300 400 500 750 1000 Double branch length: 100 200 250 300 400 500 Note:Specia specifications can be customized | Without fixing device |

| W7PK-134S | ≤5 | φ4 | |||||

| WZPK-135S | ≤8 | φ5 | |||||

| W7PK-136S | ≤12 | φ6 | |||||

| WZPK²-135SA | ≤8 | φ5 | |||||

| WZPK²-136SA | ≤12 | φ6 | |||||

| WZPK-233S | ≤3 | φ3 | Fixed ferrile thread | ||||

| WZPK-234S | ≤5 | φ4 | |||||

| WZPK-235S | ≤8 | φ5 | |||||

| WZPK-236S | ≤12 | φ6 | |||||

| WZPK²-235SA | ≤8 | φ5 | |||||

| WZPK²-236SA | ≤12 | φ6 | |||||

| WZPK-333S | ≤3 | φ3 | Movable fernile thread | ||||

| WZPK-334S | ≤5 | φ4 | |||||

| WZPK-335S | ≤8 | φ5 | |||||

| WZPK-336S | ≤12 | φ6 | |||||

| WZPK²-335SA | ≤8 | φ5 | |||||

| WZPK²-336SA | ≤12 | φ6 | |||||

| WZPK-433S | ≤3 | φ3 | Fixed ferrule flange | ||||

| WZPK-434S | ≤5 | φ4 | |||||

| WZPK-435S | ≤8 | φ5 | |||||

| WZPK-436S | ≤12 | φ6 | |||||

| WZPK²-435SA | ≤8 | φ5 | |||||

| WZPK²-436SA | ≤12 | φ6 | |||||

| WZPK-533S | ≤3 | φ3 | Movable ferrule flange | ||||

| WZPK-534S | ≤5 | φ4 | |||||

| WZPK-535S | ≤8 | φ5 | |||||

| WZPK-536S | ≤12 | φ6 | |||||

| WZPK²-535SA | ≤8 | φ5 | |||||

| WZPK²-536SA | ≤12 | φ6 |

| Model | Resistance value | Measuring range(℃) | Accuracy level | Thermal response time (T0.5S) | Diameter (mm) | Length (mm) | Installing fixing device |

| WZPK-143S | Pt100 | -200~420℃ | A or B | ≤3 | φ3 | Single length: 100 200 250 300 400 500 750 1000 Double branch length: 100 200 250 300 400 500 Note:Special specifications can be customized | Without fixing device |

| WZPK-144S | ≤5 | φ4 | |||||

| WZPK-145S | ≤8 | φ5 | |||||

| WZPK-146S | ≤12 | φ6 | |||||

| WZPK²-145SA | ≤8 | φ5 | |||||

| WZPK²-146SA | ≤12 | φ6 | |||||

| WZPK-243S | ≤3 | φ3 | Fixed ferrule thread | ||||

| WZPK-244S | ≤5 | φ4 | |||||

| WZPK-245S | ≤8 | φ5 | |||||

| WZPK-246S | ≤12 | φ6 | |||||

| WZPK²-245SA | ≤8 | φ5 | |||||

| WZPK²-246SA | ≤12 | φ6 | |||||

| WZPK-343S | ≤3 | φ3 | Movable ferrule thread | ||||

| WZPK-344S | ≤5 | φ4 | |||||

| WZPK-345S | ≤8 | φ5 | |||||

| WZPK-346S | ≤12 | φ6 | |||||

| WZPK²-345SA | ≤8 | φ5 | |||||

| WZPK²-346SA | ≤12 | φ6 | |||||

| WZPK-443S | ≤3 | φ3 | Fixed ferrule flange | ||||

| WZPK-444S | ≤5 | φ4 | |||||

| WZPK-445S | ≤8 | φ5 | |||||

| WZPK-446S | ≤12 | φ6 | |||||

| WZPK²-445SA | ≤8 | φ5 | |||||

| WZPK²-446SA | ≤12 | φ6 | |||||

| WZPK-543S | ≤3 | φ3 | Movable ferrule flange | ||||

| WZPK-544S | ≤5 | φ4 | |||||

| WZPK-545S | ≤8 | φ5 | |||||

| WZPK-546S | ≤12 | φ6 | |||||

| WZPK²-545SA | ≤8 | φ5 | |||||

| WZPK²-546SA | ≤12 | φ6 |

| Model | Resistance value | Measuring range(℃) | Accuracy level | Thermal response time (T0.5S) | Diameter (mm) | Length (mm) | Installing fixing device |

| WZPK-163S | Pt100 | -200~+420℃ | A or B | ≤3 | φ3 | Single length: 100 200 250 300 400 500 750 1000 Double branch length: 100 200 250 300 400 500 Note:Specia specification can be customized | Without fixing device |

| WZPK-164S | ≤5 | φ4 | |||||

| WZPK-165S | ≤8 | φ5 | |||||

| WZPK-166S | ≤12 | φ6 | |||||

| WZPK2-165SA | ≤8 | φ5 | |||||

| WZPK2-166SA | ≤12 | φ6 | |||||

| WZPK-263S | ≤3 | φ3 | Fixed ferrule thread | ||||

| WZPK-264S | ≤5 | φ4 | |||||

| WZPK-265S | ≤8 | φ5 | |||||

| WZPK-266S | ≤12 | φ6 | |||||

| WZPK2-265SA | ≤8 | φ5 | |||||

| WZPK2-266SA | ≤12 | φ6 | |||||

| WZPK-363S | ≤3 | φ3 | Movable ferrule thread | ||||

| WZPK-364S | ≤5 | φ4 | |||||

| WZPK-365S | ≤8 | φ5 | |||||

| WZPK-366S | ≤12 | φ6 | |||||

| WZPK²-365SA | ≤8 | φ5 | |||||

| WZPK²-366SA | ≤12 | φ6 | |||||

| WZPK-463S | ≤3 | φ3 | Fixed ferrule flange | ||||

| WZPK-464S | ≤5 | φ4 | |||||

| WZPK-465S | ≤8 | φ5 | |||||

| WZPK-466S | ≤12 | φ6 | |||||

| WZPK²-465SA | ≤8 | φ5 | |||||

| WZPK²-466SA | ≤12 | φ6 | |||||

| WZPK-563S | ≤3 | φ3 | Movable ferrule flange | ||||

| WZPK-564S | ≤5 | φ4 | |||||

| WZPK-565S | ≤8 | φ5 | |||||

| WZPK-566S | ≤12 | φ6 | |||||

| WZPK²-565SA | ≤8 | φ5 | |||||

| WZPK²-566SA | ≤12 | φ6 |

| Model | Resistance value | Measuring range(℃) | Accuracy level | Thermal response time (T0.5S) | Diameter (mm) | Length (mm) | Installing fixing device |

| WZPK-173S | Pt100 | -200~+420℃ | A or B | =3 | φ3 | Single length: 100 200 250 300 400 500 750 1000 Double branch length: 100 200 250 300 400 500 Note:Special specifications can be customized | Without fixing device |

| WZPK-174S | ≤5 | φ4 | |||||

| WZPK-175S | ≤8 | φ5 | |||||

| WZPK-176S | ≤12 | φ6 | |||||

| WZPK2-175SA | ≤8 | φ5 | |||||

| WZPK2-176SA | ≤12 | φ6 | |||||

| WZPK-273S | ≤3 | φ3 | Fixed fernile thread | ||||

| WZPK-274S | ≤5 | φ4 | |||||

| WZPK-275S | ≤8 | φ5 | |||||

| WZPK-276S | ≤12 | φ6 | |||||

| WZPK²-275SA | ≤8 | φ5 | |||||

| WZPK²-276SA | ≤12 | φ6 | |||||

| WZPK-373S | ≤3 | φ3 | Movable fernile thread | ||||

| WZPK-374S | ≤5 | φ4 | |||||

| WZPK-375S | ≤8 | φ5 | |||||

| WZPK-376S | ≤12 | φ6 | |||||

| WZPK²-375SA | ≤8 | φ5 | |||||

| WZPK2-376SA | ≤12 | φ6 | |||||

| WZPK-473S | ≤3 | φ3 | Fixed ferrule flange | ||||

| WZPK-474S | ≤5 | φ4 | |||||

| WZPK-475S | ≤8 | φ5 | |||||

| WZPK-476S | ≤12 | φ6 | |||||

| WZPK²-475SA | ≤8 | φ5 | |||||

| WZPK²-476SA | ≤12 | φ6 | |||||

| WZPK-573S | ≤3 | φ3 | Movable fernule flange | ||||

| WZPK-574S | ≤5 | φ4 | |||||

| WZPK-575S | ≤8 | φ5 | |||||

| WZPK-576S | ≤12 | φ6 | |||||

| WZPK²-575SA | ≤8 | φ5 | |||||

| WZPK²-576SA | ≤12 | φ6 |

No fixed device (porcelain patch panel)

No fixed device (porcelain patch panel) No fixed device (waterproof junction box)

No fixed device (waterproof junction box) No fixed device (ExdIIBT explosion-proof)

No fixed device (ExdIIBT explosion-proof) No fixed device (ExdIIBT explosion-proof) 2

No fixed device (ExdIIBT explosion-proof) 2 No fixed device (aviation plug)

No fixed device (aviation plug) No fixed device (Direct outgoing line)

No fixed device (Direct outgoing line) Fixed ferrule Movable ferrule thread waterproof junction box

Fixed ferrule Movable ferrule thread waterproof junction box Fixed thread without non insertion depth (waterpoof junction box)

Fixed thread without non insertion depth (waterpoof junction box) Movable ferrule chuck (waterproof junction box)

Movable ferrule chuck (waterproof junction box) Fixed ferrule chuck(waterproof junction box)

Fixed ferrule chuck(waterproof junction box) Fixed ferrule-Movable ferrule thread (ExdIIBT explosion-proof)

Fixed ferrule-Movable ferrule thread (ExdIIBT explosion-proof) Fixed thread without non insertion depth (ExdIIBT explosion-proof)

Fixed thread without non insertion depth (ExdIIBT explosion-proof) Fixed ferrule-Movable ferrule thread (ExdIICT explosion-proof)

Fixed ferrule-Movable ferrule thread (ExdIICT explosion-proof) Movable internal thread(ExdIICT explosion-proof)

Movable internal thread(ExdIICT explosion-proof) Fixed ferrule-Movable ferrule thread (aviation plug)

Fixed ferrule-Movable ferrule thread (aviation plug) Fixed ferrule-Movable ferrule thread (Direct outgoing line)

Fixed ferrule-Movable ferrule thread (Direct outgoing line) Fixed ferrule-Movable ferrule flange (waterproof junction box)

Fixed ferrule-Movable ferrule flange (waterproof junction box) Fixed ferrule-Movable ferrule flange (aviation plug)

Fixed ferrule-Movable ferrule flange (aviation plug) Screw type thermal resistance

Screw type thermal resistance Magnetic adsorption thermal resistance

Magnetic adsorption thermal resistance Flat plug-in thermal resistance with wire

Flat plug-in thermal resistance with wire All stainless steel needle type thermal resistance

All stainless steel needle type thermal resistance

Wiring instructions

Description:

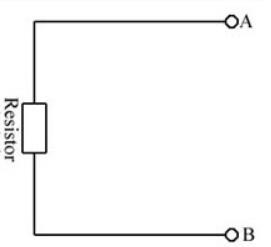

The two-wire system is suitable for places where the lead wire is not long and the temperature measurement accuracy is low.

Description:

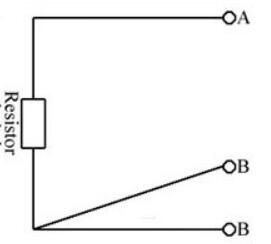

The three-wire system can reduce or eliminate the effect of resistance on ambient temperature and is used for industrial measurements with general accuracy.

Description:

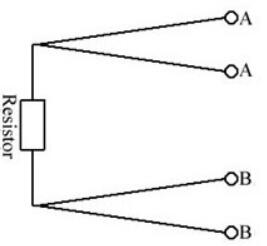

Use two wires at both ends of the resistor to provide a constant current source I for the resistor. A voltage drop occurs on the resistor. Use the other two wires to connect the display instrument for measurement. This completely eliminates the influence of the wire resistance on the ambient temperature. Mainly used for high-precision temperature measurement.

How Does a Resistance Temperature Detector Work?

Resistance temperature detector (RTD) sensors measure temperature based on the principle of a metal resistor.

The RTD operates on the principle that the electrical resistance of metal changes predictably with temperature, in a substantially linear and repeatable manner. RTD temperature sensors have a positive temperature coefficient (resistance increases with temperature). The resistance of the element at base temperature is proportional to the inverse of its length and cross-sectional area.

These resistors are typically made of materials such as platinum, copper, or nickel and have a precise resistance value at a specific temperature (such as 0°C or 100°C). When the temperature changes, the metal’s resistance also changes, and this change is proportional to the temperature change.

To measure temperature, an RTD sensor is connected to a measuring instrument such as a multimeter or temperature transmitter. The measuring device sends current into the sensor circuit and reads the voltage across the RTD. This voltage reflects the sensor’s resistance and, in turn, the current temperature. The measuring device converts the voltage across the sensor into a temperature display or control signal, enabling accurate temperature monitoring.

Read more about:

Understanding RTD Sensors: Key to Measure Industrial Temperature

Which Is Better, an RTD or a Thermocouple?

The following are significant differences between RTDs and thermocouples, ranging from their operating principles to their performance in specific industrial applications and their required process temperatures.

Temperature Range

RTDs: With a temperature range of -200°C to 660°C, they are suitable for medium-temperature applications.

Thermocouples: They can measure temperatures from -270°C to 2300°C, making them ideal for extreme temperature applications.

Accuracy

RTDs: Offer higher accuracy (+/- 0.012°C) with excellent repeatability and drift performance.

Thermocouples: Offer average accuracy, with most base metal thermocouples typically achieving an accuracy of 0.75% of reading or +/- 1.0°C, whichever is greater.

Sensitivity

RTDs: Due to their larger mass and design, they have a slower response.

Thermocouples: They respond quickly to temperature changes, making them ideal for dynamic environments.

Durability

RTDs are more susceptible to physical shock due to their platinum coil sensor design. Thermocouples: Very rugged, able to withstand vibration, high pressure, and corrosive environments.

Cost

RTDs are more expensive due to accuracy and material cost.

Thermocouples: Generally, they are less expensive and easier to replace.

Is an RTD or a thermocouple better and more suitable? It depends on the specific application requirements.

RTDs should be used when:

- Accuracy is critical, such as in pharmaceutical or laboratory research.

- A medium temperature range (-200°C to 660°C) is required.

- Long-term stability is essential.

Thermocouples should be used when:

- Extreme temperatures are involved, such as in industrial furnaces or cryogenic storage.

- Durability and fast response time are required, such as in aerospace or automotive applications.

- Cost is a limiting factor.

Read more about: Differences Between Thermocouples: Type S, K, N, J, E, T

More Featured Temperature Sensors and Measurement Solutions

- Liquid Nitrogen Pressure Measurement – Pipeline and Tank

- High Temperature Pressure Transducers|800℃~1200℃

- Fluid Pressure Sensors for Industrial Liquids Pressure Measurement

- Industrial HART Pressure Transmitters and DP Transmitters

- Top 3 Flow Meters for PVC Pipes

- Industrial Pressure Transmitters: 7 Sensor Principles and 4 Main Types!

- Pipe Flow vs Pressure – Relationship & Calculate Tools

The temperature measurement principle of Resistance Temperature Detector is based on the characteristic that the resistance value of a conductor or semiconductor changes with temperature to measure temperature and temperature-related parameters. Most Resistance Temperature Detectors are made of pure metal materials, with platinum and copper being the most widely used. Materials such as nickel, manganese and rhodium have begun to be used to manufacture thermal resistors.

Resistance Temperature Detectors usually need to transmit resistance signals to computer control devices or other secondary instruments through leads. We at Sino-Inst produce and supply various types of industrial Resistance Temperature Detectors, mainly the PT100 type.

If you need to purchase industrial temperature sensors such as PT100, or have related questions, please feel free to contact us.

Industrial Resistance Temperature Detector Series Products

Resistance temperature detectors (RTDs) are sensors that use the temperature-dependent resistance of metals to measure temperature. They are widely used in industry and laboratories. They can measure the temperature of liquids, vapors, gases, and solid surfaces within a temperature range of -200°C to 650°C.

Product SKU: Industrial Thermal Resistances

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 35.80

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)