Turbine Water flow meters are a type of velocity flow meter that have found widespread use in a variety of industrial applications. Turbine flow meters are particularly useful for measuring clean, low-viscosity fluids, making them an ideal choice for water flow measurement in many applications.

This blog post delves into everything you need to know about turbine water flow meters—what they are, how they work, their advantages, limitations, and how to select the right one for your needs.

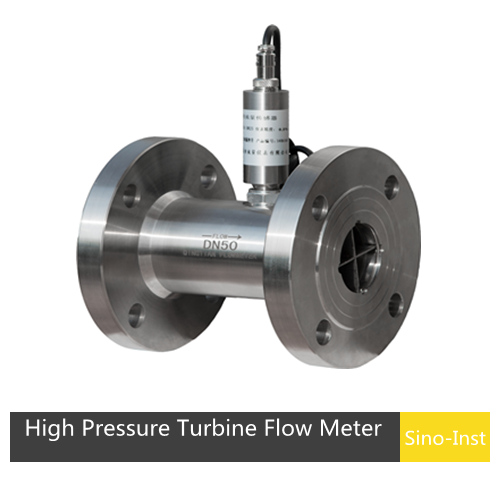

Featured turbine flow meter for water

Types of Turbine Flow Meters for Water

Operative Elements of a Turbine Flow Meter for Water

- Turbine Rotor: It is generally made of corrosion-resistant materials such as stainless steel to handle different water conditions.

- Bearings: These support the rotor and ensure smooth operation. High-quality bearings are crucial for reducing wear and extending the lifespan of the meter.

- Magnetic Pickup or Sensors: These devices detect the turbine’s rotation and convert it into an electrical signal, which is then processed to calculate flow rate.

- Housing: The casing that holds the internal components. It is usually made from stainless steel, aluminum, or durable plastics, depending on the application.

How Does a Turbine Water Flow Meter Work?

The working principle of a ‘turbine type water flow meter’ is founded on the mechanical energy of the flowing fluid. As water passes through the meter, it strikes the turbine blades, causing the rotor to spin. The speed of rotation is directly proportional to the flow velocity of the water. Turbine flow meters are designed to measure the flow of liquid in pipes on a volumetric basis and they do so accurately.

The rotating speed of the blades is measured by attaching a magnet onto the blades themselves. These magnets then pass a piece of metal embedded at a designated point within the casing. This passing contact allows us to calculate the time passing between each contact which in turn allows us to calculate the speed of the fluid passing through. This particular system means that regardless of the fluid’s direction, the meter works in exactly the same way.

The flow meter housing contains rotor blades connected to a rod and affixed on bearings in order to spin. As the fluid moves through the meter, the rotor blades turn. The faster the fluid moves, the faster the rotor blades turn.

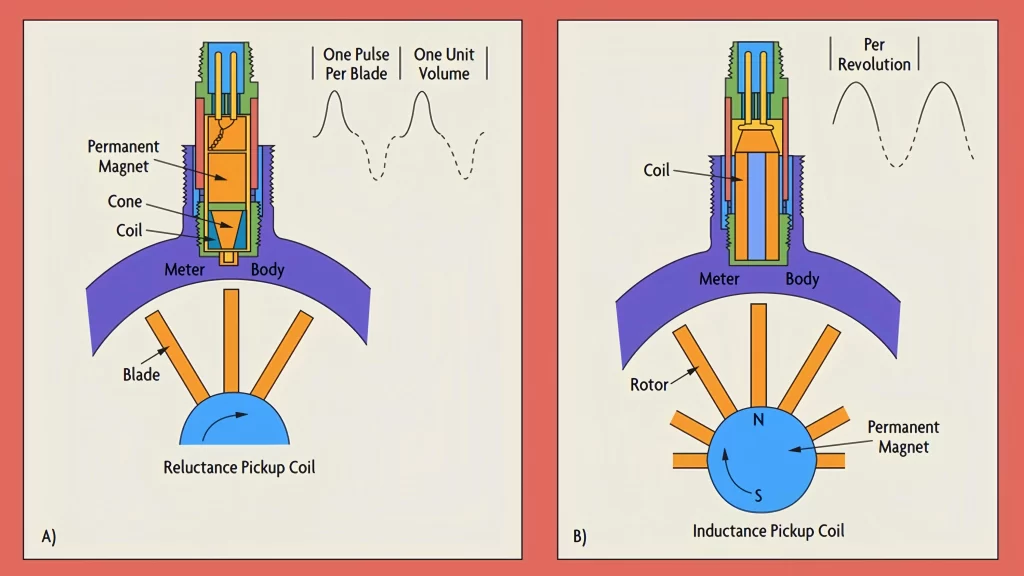

Two Variation of Designs of Turbine Water flow meter

In the reluctance pick-up, the coil is a permanent magnet and the turbine blades are made of a material attracted to magnets. As each blade passes the coil, a voltage is generated in the coil (Figure A). Each pulse represents a discrete volume of liquid. The number of pulses per unit volume is called the meter’s K-factor.

In the inductance pick-up, the permanent magnet is embedded in the rotor, or the blades of the rotor are made of permanently magnetized material (Figure B). As each blade passes the coil, it generates a voltage pulse. In some designs, only one blade is magnetic, and the pulse represents a complete revolution of the rotor.

Advantages of Using a Turbine Flow Meter for Water

- Low cost;

- Accuracy;

- Precision;

- Ease of set up;

- Ease of operation;

- Usable across a wide spectrum of applications;

- Works accurately at very low flow rates;

- Capable of handling high pressure;

- The measuring device can be heated;

- High temperature-low temperature type can be customized;

Limitations of Turbine Water Flow Meters

While turbine flow meters offer many advantages, they also have limitations that must be considered when selecting a meter for your application.

- If samples are of high viscosity, errors may occur;

- Calibration checks are frequently required;

- Samples need to be clean (there is no filter system within the meter);

- Minimum requirement of 5 diameter downstream and 15 diameter upstream pipes are required;

- Does not work with swirling fluids effectively;

- Specifications of viscosity are critical;

Applications of Turbine Flow Meters for Water

Turbine meter could be used in process industries providing precision, corrosion resistance, intrinsic safety, good temperature and pressure rating and ease of installation.

Some of the important application areas are listed below:

- Water Treatment and Distribution

- Agriculture and Irrigation

- HVAC Systems

- Fire Protection Systems

- Residential Water Usage

Choosing the Right Turbine Flow Meter for Water: Key factors

- Pipe Size

- Flow Rate

- Water Quality

- Installation Requirements

- Maintenance

- Temperature

- Pressure

- Signal ouput

More Water Flow Measurement Solutions

- Pulse Output Flow Meters for Better Water Flow Measurement

- Ultrasonic Clamp On Flow Meter – For Easier Water Flow Measurement

- Role of Hydrostatic Level Transmitters In Well Water Level Monitoring Process

- Water Level Pressure Transducers

- Choosing the Right Inline Water Flow Meter

- Cooling Water Flow Measurement

- Flow Meters for Domestic Water-Potable Water-Drinking Water

- Wastewater flow meter

- Water Flow Meter Types

Turbine water flow meters are an excellent choice for a wide range of applications due to their accuracy, affordability, and durability. However, they are best suited for clean, low-viscosity liquids and steady flow conditions.

By understanding their advantages and limitations, and considering factors such as flow rate, water quality, and installation requirements, you can select the right turbine flow meter for your needs. Sino-Inst will be your professional supplier of high quality Turbine water flow meters.

-1.jpg)