Submersible Level Transmitter is a low-cost liquid level sensor. It uses a high-performance diffused silicon piezoresistive pressure sensor as the measuring element. It accurately measures the static pressure of the liquid that is proportional to the liquid level depth. It is converted into a standard ( Current or voltage) signal output. Establish a linear correspondence between the output signal and the liquid level depth to achieve the measurement of liquid depth.

Features of Submersible Level Transmitter

Technical Parameters

| Performance parameters | Submersible liquid level transmitter |

| model | SI-802M4 |

| Power supply | 12~36V power supply |

| output signal | 4~20mA, 1~5V, 0~20mA, 0~5V, RS485, etc. |

| Measuring range | 0-1 meter; 0-3 meter; 0-5 meter; 0-10 meter; 250 meters can be customized |

| Compensation temperature | -10~70℃ |

| Storage temperature | -40~125℃ |

| Medium temperature | -20~85℃ |

| Housing protection | Sensor IP68; Housing IP65 |

| Comprehensive accuracy | 0.2%FS, 0.3%FS, 0.5%FS optional |

| Zero temperature drift | ±0.03%F.S/C |

| Sensitivity temperature drift | ±0.03%F.S/C |

| overload pressure | 200%F.S |

| long term stability | ±0.2%F.S/y |

| Natural frequency | 5KHz~650KHz |

| Electrical connections | Waterproof connector, stainless steel explosion-proof connector; without display, that is, direct outlet; |

| Measuring medium | Oil, water and other non-corrosive media |

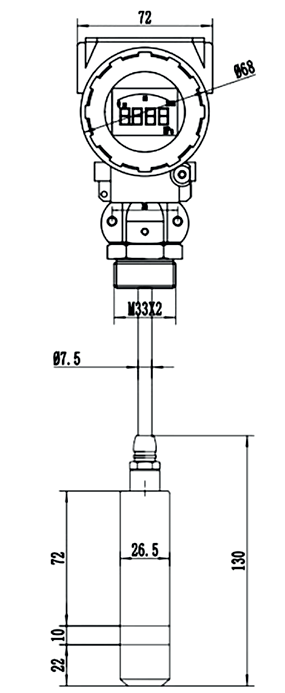

| process connection | Sensor input type; shell threaded connection/flange connection (can be customized) |

Submersible Level Transmitter Working Principle

The basic working principle of the submersible level transmitter is hydrostatic liquid level measurement, that is, the principle that the measured static pressure of the liquid is proportional to the height of the liquid.

In liquid media, the pressure generated at a certain depth is generated by the weight of the medium itself above the measuring point. It is proportional to the density of the medium and the local acceleration due to gravity.

The proportional relationship between them is reflected by the formula P=ρGH.

Where P=pressure, ρ=medium density, G=gravitational acceleration, H=depth of measuring point.

So the physical quantity measured by the submersible level transmitter is actually pressure. The actual liquid level must be obtained through conversion after knowing the two parameters of density and gravity acceleration. Such conversion is usually performed through secondary instruments (transmitters) or PLC in the industrial field.

A submersible level transmitter generally uses the piezoresistive effect of diffused silicon or ceramic sensitive elements to convert static pressure into electrical signals. Temperature compensated and linearly corrected. Convert to 4-20mADC standard current signal output.

submersible level transmitter installation

- Choose a place that is easy to operate and maintain for installation, thread or flange. We support thread or flange size customization.

- There should be no vibration or tremor in the installation area.

- There should be no heat source in the installation location.

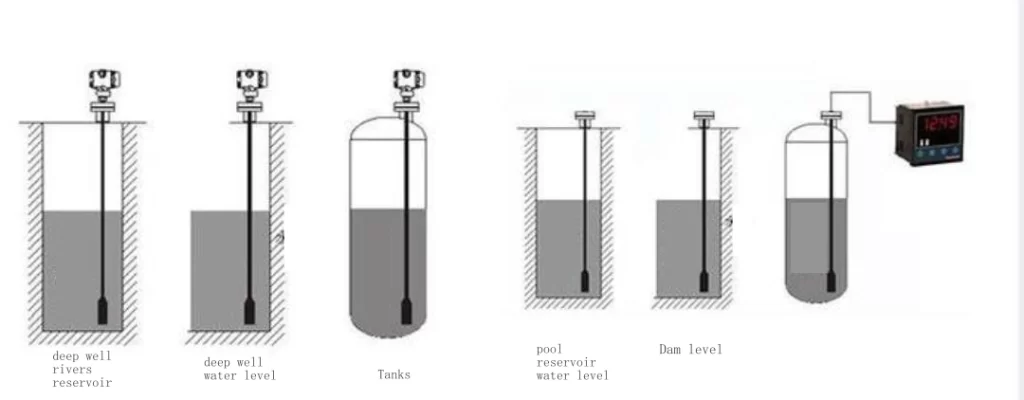

- When installing the submersible liquid level transmitter, the probe should sink to the bottom of the container.

- If there is sediment at the bottom of the container and it is very thick, place the probe above the sediment.

- In situations where there is large vibration, a steel wire can be wrapped around the input liquid level sensor. Use the steel wire to absorb shock to avoid breaking the cable.

- The installation direction of the submersible liquid level sensor is vertical, and the submersible installation position should be away from the liquid inlet and outlet and the agitator.

- When measuring the liquid level of flowing or stirring liquid, usually a steel pipe with an inner diameter of about Φ45mm (punch a number of small holes at different heights on the opposite side of the liquid flow direction to allow water to enter the pipe unobstructed) is fixed in the water. Then put the input liquid level sensor into the steel pipe and it can be used.

- When the medium fluctuates greatly and the gas cable is very long, the probe should be fixed with a sleeve. To prevent the probe from swinging and affecting the measurement accuracy.

- Connect the power and signal cables: Connect the power and signal cables of the level sensor according to the wiring method mentioned above. Make sure the wiring is firm and reliable to avoid looseness or poor contact.

- Debugging and calibration: After the installation is completed, debug and calibrate the liquid level meter. According to the user manual of the liquid level meter, perform the corresponding calibration steps to ensure that the liquid level meter can accurately measure the liquid level.

More Featured Industrial Level Transmitters and Measurement Solutions

Submersible Level Transmitter is a commonly used liquid level measuring device. Its basic principle is to insert a sensor probe into the liquid and calculate the liquid level by measuring the pressure change felt by the probe.

Submersible Level Transmitter is suitable for liquid level measurement and control in the fields of petroleum, chemical industry, power plants, urban water supply, and hydrological exploration. The Submersible Level Transmitter produced by our Sino-Inst has been screened for long-term aging, and the product performance is stable and reliable. It can be applied to open-air sites with harsh environments, and can display liquid level, zero point, and full range migration on site. Can be customized 0-10m-50m-250m.

If you need to customize the Submersible Level Transmitter, please feel free to contact our sales engineers!

Submersible Level Transmitter | 0-10m-50m-250m

Submersible Level Transmitter is a low-cost liquid level sensor. 0-10m-50m-200m. Through liquid hydrostatic pressure measure level-depth in water and wastewater.

Product SKU: Submersible Level Transmitter | 0-10m-50m-200m

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 119

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)