Refrigerant flow meters can accurately measure the refrigerant flow. It is not only related to the stable operation of the refrigeration system but also directly affects the production efficiency and cost control of the enterprise.

There are more than 80 substances that can be used as refrigerants, the most commonly used are ammonia, freon, water, and a few hydrocarbons. So, how do you choose the right refrigerant flow meters?

Let’s start with Refrigeration

What is refrigeration?

The refrigeration process plays a cardinal role for humanity, just think of the household refrigerators and the food cold chain: from the production to the processing and packaging, to transport and distribution, it allows you to store fresh meat, fruits and vegetables, dairy products and other foods making them safe for consumers (the temperature, which varies on average from -1 to + 8 ° C slows down biochemical reactions). In the “controlled atmosphere” refrigeration, the refrigerant treatment is accompanied by a qualitative change in the atmosphere surrounding the food.

In the healthcare sector, refrigeration technology can be used for the conservation of cells, embryos, tissues, organs, for the transport of medicines and vaccines, for cryosurgery and cryotherapy; it is also necessary in many industrial processes (in the chemical, plastics sector etc.), as well as in research laboratories (for experiments on superconductivity, on vacuum systems etc.) and in astronomy (for cooling the CCD and CID sensors used in telescopes).

Refrigeration and air conditioning have a strong impact on global warming. The use of Chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) has been banned because these gases contribute to the depletion of stratospheric ozone. They have largely been replaced by Hydrofluorocarbons (HFCs) which are however potent greenhouse gases.

However, the use of lower environmental impact refrigerants must go hand in hand with improved energy efficiency: in fact, energy consumption generally contributes 60-80% to the climatic impact caused by a refrigeration system in its useful life. Restrictions on the use of gas have given a new boost to research and experimentation aimed at making systems more efficient. Performance improvements involved all components: exchangers, valves, probes, flowmeters, control systems, etc.

Importance of Refrigerant flow meter

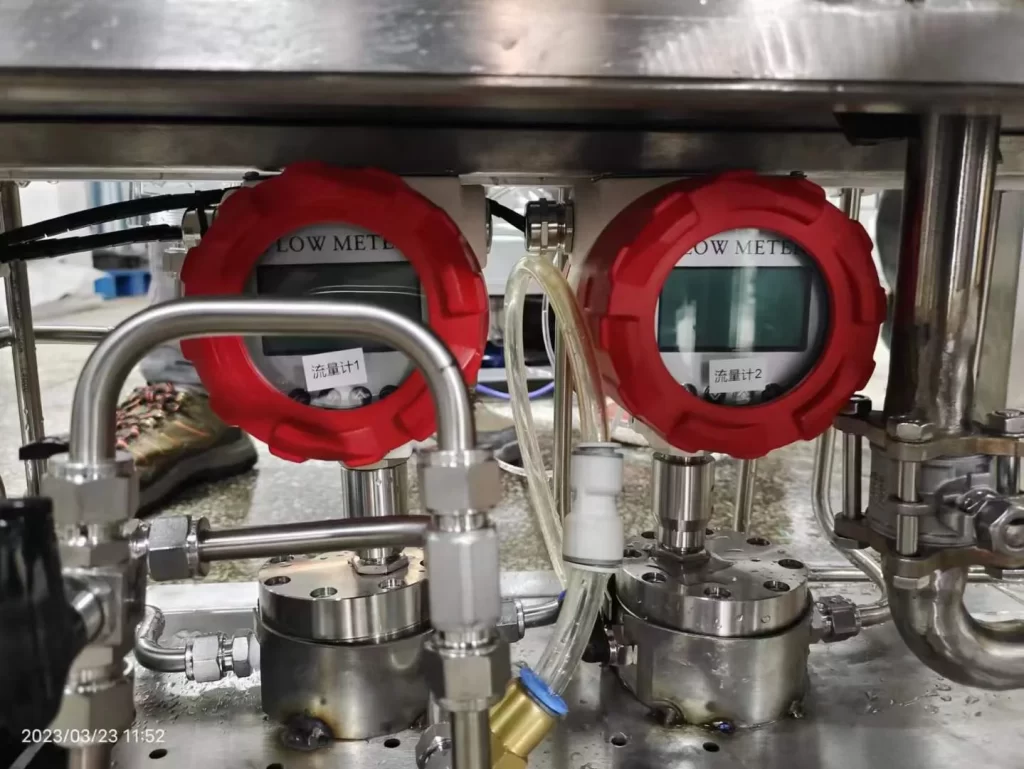

Featured Refrigerant Flow Meters

There are many types of flow meters that can measure refrigerant flow. We can choose the appropriate model according to the actual measurement parameters.

Types of refrigerant flow meters:

- Gear flowmeter

- Turbine flowmeter

- Electromagnetic flowmeter

- Mass flowmeter

- Vortex flowmeter

Refrigerant Mass Flow Meter

The Coriolis mass flow meter is the perfect choice for use as a refrigerant mass flow meter.

Mass flow meters measure the volume or mass of a gas or liquid passing through a system at a fixed point. Mass flow meters measure mass, and volumetric flow rates and have different names depending on the industry and their use.

Refrigerant mass flow meters provide a high-fidelity representation of the refrigerant flow in systems that deal with variable temperatures and pressures. These meters are essential for industries where precise control of refrigerant is critical, such as in pharmaceuticals, food processing etc.

Why R134a Refrigerant Flow Meters are Crucial?

‘R134a’ is a hydrofluorocarbon (HFC) refrigerant with first-class thermodynamic properties, making it a best-selling choice in different cooling systems.‘R134a’ is a widely used refrigerant, particularly in automotive air conditioning systems, residential and commercial refrigeration, and other cooling applications.

Properly managing the flow of R134a is not only essential for energy efficiency but also for reducing emissions and maintaining conformity with environmental regulations.

Utilization of Refrigerant Flow Meters

- HVAC Systems

- Automotive Air Conditioning

- Commercial Refrigeration

- Industrial Cooling

- Pharmaceutical and Healthcare

Fundamental Conditions for Choosing a Refrigerant Flow Meter

- Refrigerant type;

- Refrigerant state, gas or liquid;

- Accuracy necessities;

- Type of Refrigerant;

- Flow Range;

- System Pressure and Temperature;

- Installation conditions;

- Signal output;

More Flow Measurement Solutions

- Flowmeter Calibration & Recalibration

- Ultrasonic Flow Meter Technology

- Thermal Mass Flow Meter Technology

- Coriolis Mass Flow Meter Technology

- Differential Pressure Flow Meter Technology

- Vortex Flowmeter Technology

- Turbine Flowmeter Technology

- Magnetic Flowmeter Technology

- 4-20mA Flow Meters | Flow Meter Signal Output Guide

- Analog Flow Meters: An Encompassing Guide

- Industrial Hydraulic Flow Meters | Mechanical & Digital

Knowing the different types of refrigerant flow meters and their usage will help you select the right one for your specific needs. Ensuring that your cooling systems operate efficiently while minimizing energy consumption and environmental impact.

Sino-Inst, refrigerant flow meter manufacturer. For example: Ammonia, Freon-12, Freon-22, R134, R22, R410a.

Sino-Inst refrigerant flow meter, made in China, good quality, excellent price. Our flow measurement instruments are widely used in China, India, Pakistan, the United States and other countries.

-1.jpg)