Hydrogen pressure transmitters can convert gas hydrogen or liquid hydrogen pressure signals into standard electrical signals. Hydrogen has strong reducing properties and is a common industrial gas.

Sino-Inst supplies hydrogen pressure transmitters specifically designed for industrial hydrogen measurement. Including measuring gaseous hydrogen, low-temperature liquid hydrogen, etc. It has many advantages in pressure monitoring applications of hydrogen manufacturing and purification equipment and hydrogen storage and transportation equipment.

Characteristics and Industrial Uses of Gaseous Hydrogen

Hydrogen has strong reducing properties and is a common industrial gas. It has a large number of applications in chemical, electronic, automotive, aerospace and other industries.

Hydrogen diffuses easily and rapidly, and will become a combustible gas when the mixture ratio with air exceeds 4%. Therefore, strict process and process control are required during preparation, storage and transportation.

- Equipment is prone to “hydrogen embrittlement” and “hydrogen penetration” phenomena

- Hydrogen is flammable and explosive

- High requirements for product accuracy and sealing

Industrial uses of hydrogen:

- Hydrogen is used in many petroleum refineries to produce petroleum products such as diesel and gasoline. It helps avoid many impurities, such as sulfur, in the final products produced by these refineries.

- Different chemical industries require hydrogen to produce important hydrogen-based compounds. Such as synthetic ammonia and methanol.

- Manufacturers of fertilizers and other agricultural products require hydrogen. Because ammonia is an important component of most fertilizers.

- The manufacture of metal products requires hydrogen for atomic hydrogen welding. This is an important arc welding equipment.

- Electronic products, such as semiconductors, display screens and LED lights, require hydrogen for the reduction process.

- The glass industry requires hydrogen to prevent glass from oxidizing. The final product is also manufactured from flat glass.

- Hydrogen is also needed in the power generation and aviation industries. The gas can be used as fuel when supplied through pipelines from hydrogen plants.

Characteristics and Industrial Uses of Liquid Hydrogen

Liquid hydrogen is a liquid obtained by cooling hydrogen gas. It is a colorless, odorless, high-energy, low-temperature liquid fuel. The normal boiling point of hydrogen at one atmospheric pressure is 20.37 K (-252.78°C), and the freezing point is 13.96 K (-259.19°C). Compared with hydrogen, it has the advantages of high density and high purity. It can effectively reduce transportation costs and improve the unit capacity of transportation equipment.

Liquid hydrogen is an important component of the hydrogen energy industry. Its extremely high purity and extremely low temperature can effectively solve the problems of long-distance and large-scale transportation and trade of hydrogen. Has a wide range of application scenarios:

- As launch vehicles such as communications satellites, spacecraft, and space shuttles;

- Used as storage fuel in hydrogen refueling stations and hydrogen fuel cell vehicles;

- Used as chemical fuel in industry;

- Provide a deep low temperature environment to achieve superconducting state;

- Ultrapure hydrogen used in semiconductor manufacturing processes;

- Liquid hydrogen can also be used as a fuel for new energy vehicles;

- Liquid hydrogen can also be combined with liquid fluorine to form a high-energy propellant.

Technical Challenges of Hydrogen Pressure Measurement

There are often technical challenges when pressure transmitters are exposed to hydrogen.

Large amounts of metal can become brittle when exposed to hydrogen. Hydrogen atoms seeping into the metal mesh change the material’s strength. In the worst case, this can cause the material to break. Or simply put, the pressure transmitter will begin to leak or be completely destroyed.

When it comes to pressure transmitters, especially the membrane required for pressure measurement, plays a decisive role. Atomic hydrogen not only penetrates the metal but also penetrates it through diffusion.

This has some consequences: When using the varistor measuring principle, things can get serious if hydrogen reacts with the internal transmission medium or accumulates in the medium. Initially the measurement results are falsified. However, this can lead to complete destruction of the transmitter in individual cases.

The entry of hydrogen gas will also change the resistance structural characteristics of the transmitter film measuring bridge on the instrument. Although this process is reversible, it results in at least temporary detuning of the bridge. This can lead to tampering of the measurement signal.

Therefore, we need to choose appropriate materials to meet the measurement impact of hydrogen to the greatest extent. For example, we can choose a gold-plated diaphragm solution to reduce the penetration of hydrogen and prevent the occurrence of hydrogen embrittlement. Or, we can customize the most suitable Hydrogen pressure transmitter according to the user’s measurement parameters.

Featurd Industrial hydrogen pressure transmitters

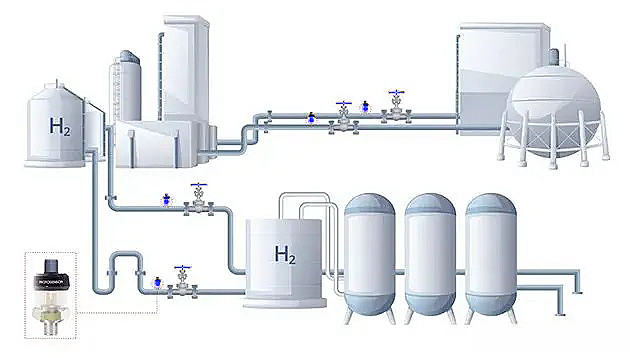

Hydrogen pressure transmitter industrial applications:

- Containerized, skid-mounted and various customized hydrogen production systems

- PEM fuel cell

- Hydrogen fuel cell test station

- Hydrogen fuel cell vehicle testing system, etc.

- Pressure measurement of gas and liquid hydrogen in hydrogen storage cylinders and tank trucks during hydrogen transportation.

More Pressure Measurement Solutions

- Pressure Transducer Output Signal Guide

- Industrial Smart Pressure Transmitters 4-20mA, HART, RS485 Modbus

- More Powerful Pressure Transmitter with Diaphragm Seal and Capillary

- Vacuum Pressure Sensors | Vacuum-Negative Pressure Measurement

- Industrial Pressure Sensors for High Pressure Measurement

- Capacitive Pressure Transmitter | Manufacturer’s Guide & Product List

- Industrial Water Pressure Measurement and Monitoring

- Tank Level Measurement with Pressure Transmitters/DP Transmitters

- Featured Stainless Steel Pressure transducers | Best Price

- Liquid Nitrogen Pressure Measurement – Pipeline and Tank

Because hydrogen is easily diffused, flammable and explosive. In order to ensure the safety during its transportation, a hydrogen pressure transmitter is required to strictly monitor its pressure.

The application of hydrogen pressure transmitters can improve production efficiency and quality, reduce production costs, and also improve production safety.

Sino-Inst supports customization of hydrogen pressure transmitters. Hydrogen flow meters are also supplied. If you need to purchase a hydrogen pressure transmitter or have related technical questions, please contact our engineers!

-1.jpg)