The ability to measure flow rates externally without the need for penetration of the fluid-carrying pipe is a boon in modern-day Industrial processes. That’s why, Non-invasive, Non-intrusive flow meters is becoming a perfect pick for sensitive fluids.

Ultrasonic flow meter as a favourite option as Non-invasive, Non-intrusive flow meter. It’s a non-contact flow meter. Working principles, advantages, applications, and how they are changing the landscape of flow measurement will be a great read for any customer, who wants to invest in this market.

The Core of Non-Invasive and Non-Intrusive Flow Meters

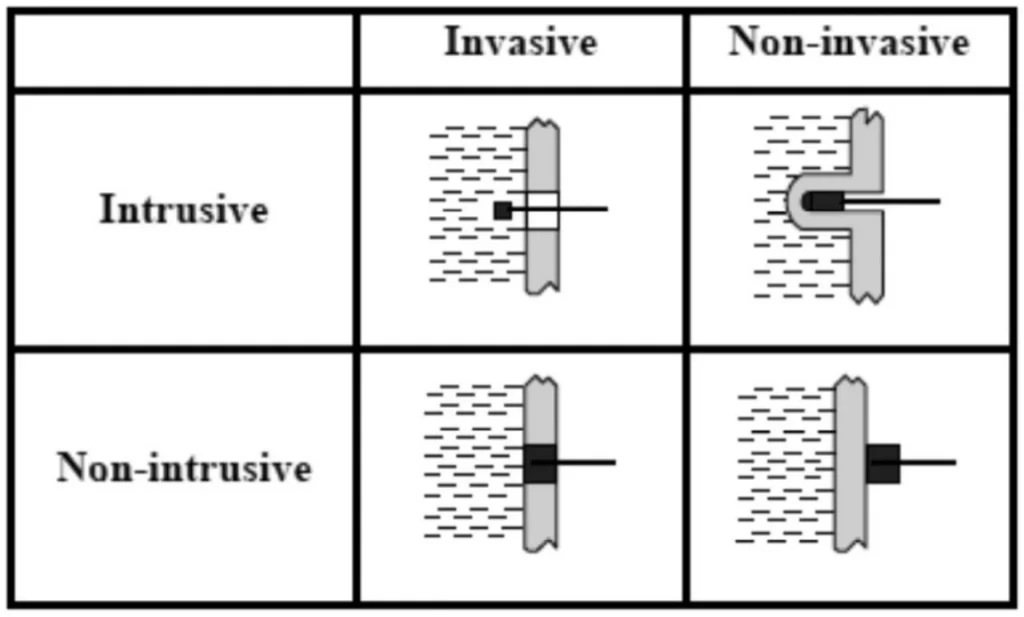

Non-Invasive Flow Meters: Flow meters that clamp onto the outside of a pipe operate non-invasively, without moving parts. They cause no pressure drop, risk no damage from the process liquid, and entail little maintenance.

Non-Intrusive Flow Meters: Flow meters will be placed/mounted outside the pipeline but either it can be in-contact or no-contact with the process flow.

Non intrusive devices do not interfere with the flow profile. No pressure drop is observed meaning that these devices are more cost effective to operate. They are also non-invasive which means they do not come into contact with the fluid being measured.

Comparison Between Traditional and Non-Invasive, Non-Intrusive Flow Meters

| Attributes | Traditional | Non-Invasive,non- intrusive |

| Installation process | Often requires cutting the pipeline and interrupting the flow, which can cause potential leakage and contamination risks. | Can be installed without interrupting the flow or cutting the pipeline, avoiding any medium leakage or contamination. |

| Maintenance | Typically has moving parts that come into contact with the fluid, which can wear out over time and require more frequent maintenance. | Has no moving parts and does not come into direct contact with the fluid, resulting in lower wear and tear, and consequently lower maintenance costs |

| Measurement method | Typically relies on mechanical methods, such as turbine or positive displacement, which measure the flow rate by direct contact with the fluid. | Uses advanced methods such as the Transit Time Method or Doppler Method, which involve measuring the time or frequency of ultrasonic waves to determine flow rate. |

| Impact on fluid flow | Can introduce a pressure drop or disturb the flow due to its intrusive nature. | Does not obstruct the flow of fluid, ensuring no pressure drop or flow disturbance. |

| Applicability | Often limited by the type and size of the pipes it can be installed on, with some materials and sizes being incompatible. | Suitable for a wide range of pipe materials and sizes, especially those not compatible with traditional flow meters. |

Advantages of Non-Invasive and Non-Intrusive Flow Meters over Traditional Flow Meters

- No Disruption to Flow

- Ease of Installation

- Reduced Risk of Contamination

- Lower Maintenance

- Minimal Risk of Leaks

Types of Non-Invasive and Non-Intrusive Flow Meters

The Ultrasonic flow meters are both non-intrusive and non-invasive.

These devices use high-frequency sound waves to measure the flow of liquids or gases through a pipe.

Ultrasonic flow meters are widely used in applications where precise flow measurement is critical and where non-intrusive methods are needed.

How Ultrasonic Flow Meters Work

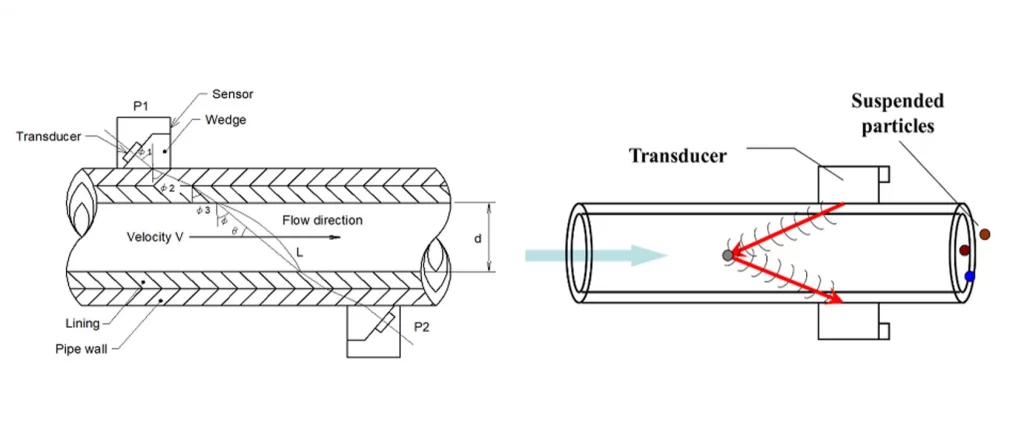

Uses the propagation characteristics of ultrasonic waves in the fluid for measurement, mainly including the Transit Time Method and Doppler Method.

Transit-time Ultrasonic Flow Meters: These meters work by measuring the time it takes for sound waves to travel downstream and upstream in the pipe. The difference in time between these two measurements is used to calculate the flow rate.

Doppler Ultrasonic Flow Meters: These meters use the Doppler effect, where the frequency of the reflected sound waves changes based on the velocity of the fluid. This change in frequency is then used to calculate the flow rate.

Applications

- Water and Wastewater Treatment

- Oil and Gas industry

- Food and Beverage

- Chemical Engineering

- Pharmaceuticals

Advantages of Ultrasonic Flow Meters

- Highly Accurate

- No Pressure Loss

- Suitable for Large Pipes

- Non-Invasive, Non-Intrusive

Ultrasonic Design Variations

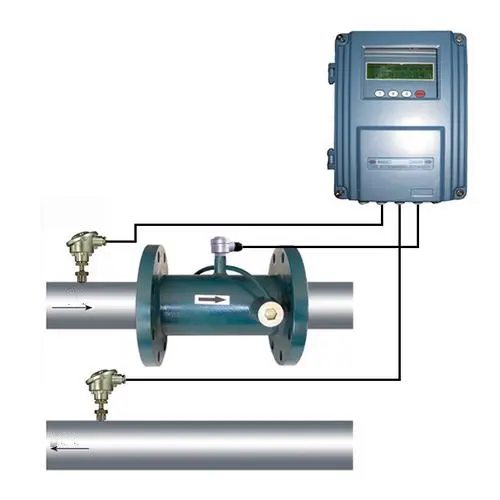

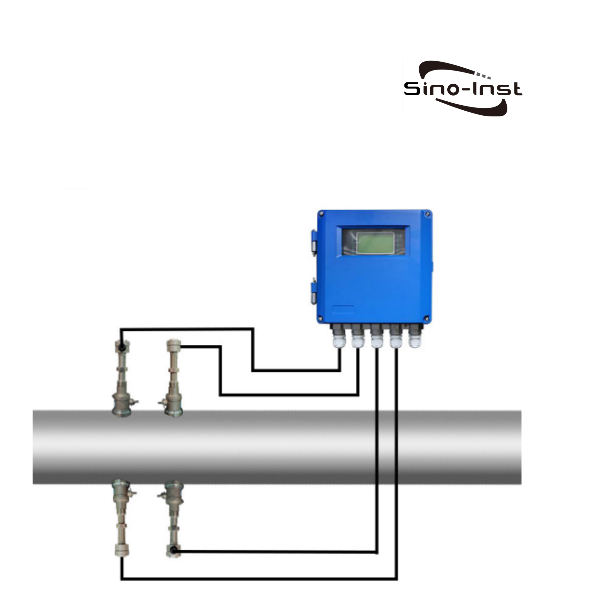

In terms of ultrasonic sensors, our ultrasonic flowmeters have single-channel, dual-channel and even four-channel versions. They can be applied to different measurement requirements.

In terms of the structure of ultrasonic flowmeters, our ultrasonic flowmeters have wall-mounted host, handheld host, compact clamp-on host, etc.

In terms of ultrasonic technology, there are mainly time difference type, Doppler, etc. The time difference type is mainly suitable for single pure medium measurement. The Doppler type can be used for mud, bubbles, impurities and other medium measurement.

Choosing the Right Ultrasonic Flow Meter

Ultrasonic flow meters are also ideal for applications where low-pressure drop is needed and low maintenance is required.

An ultrasonic Doppler flow meter is a volumetric flow meter that is ideal for aerated liquids such as wastewater or slurries. Transit time ultrasonic flow meters are ideal for clean liquid applications such as water and oil.

When choosing an ultrasonic flow meter, we recommend that you consider the following points:

- Measuring medium

- Whether the medium contains bubbles or impurities.

- Pipe diameter

- Pipe material

- Medium temperature

- Signal output

More Flow Measurement Solutions

- Right Flow Meter For Breweries: Exploring Food Grade Flow Meters

- An Extensive Guide On Magnetic Inductive Flow Meters

- Flow Measurement For Powders And Granular Materials: Solid Flow Meter

- Rotameter vs Flow Meter

- Flowmeter Calibration & Recalibration

- Ultrasonic Flow Meter Technology

- Thermal Mass Flow Meter Technology

- Coriolis Mass Flow Meter Technology

- Differential Pressure Flow Meter Technology

- Vortex Flowmeter Technology

- Turbine Flowmeter Technology

- Magnetic Flowmeter Technology

In conclusion, the evolution of non-invasive, non-intrusive, and non-contact flow meters is transforming industries by offering more accurate, reliable, and cost-effective ways to measure flow. As industries continue to demand more efficiency, safety, and accuracy in their operations, non- invasive and non-intrusive flow meters will be always in use.

The Ultrasonic Flow meter options from Sino-Inst are quite reasonable and customers are never disappointed after investing money on these advanced flow meter options.

-1.jpg)