Explosion-proof ultrasonic level meters are specifically designed for level measurement in flammable and explosive environments. Die-cast aluminum alloy waterproof and explosion-proof housing.

Sino-Inst explosion-proof ultrasonic level meter has an explosion-proof grade of Ex dⅡCT6 Gb. It is primarily used for monitoring the level of tanks containing media such as diesel, gasoline, and lubricating oil.

Non-Contact Measurement Principle

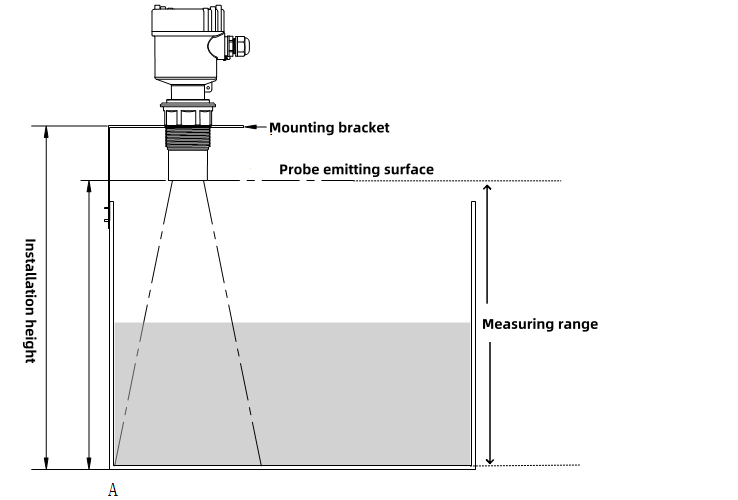

Ultrasonic level meters are based on the principle of acoustic echo ranging. A high-frequency ultrasonic pulse is emitted by a transducer (probe). Upon encountering the surface of the measured medium, it is reflected back. Part of the reflected echo is received by the same transducer and converted into an electrical signal.

Ultrasonic pulses travel at the speed of sound. The time interval between emission and reception is proportional to the distance between the transducer and the measured surface.

The relationship between this distance, S, the speed of sound, C, and the transmission time, T, can be expressed as: S = C × T/2.

Because the transmitted ultrasonic pulse has a certain width, the reflected wave in a small area close to the transducer overlaps with the transmitted wave, making it impossible to distinguish and measure the distance. This area is called the measurement blind zone. The size of the blind zone depends on the model of the ultrasonic level meter.

Read more about: Ultrasonic Level Transducer: Working Principle,Types and Benefits

Case Sharing

A customer wanted to monitor the liquid levels of multiple diesel tanks. The customer consulted our website and finally determined the parameters as follows:

- Explosion-proof ultrasonic level meter

- Measuring range: 0-15m

- Accuracy: 0.5%

- Measures diesel fuel

- Power supply: 24V

- Local digital display

- Signal output: 2-wire, 4-20mA

- Tank top mount

- English version

Advantages

1. Safe, Waterproof, And Explosion-Proof

The instrument features a waterproof, explosion-proof, die-cast aluminum alloy housing; its explosion-proof rating reaches Ex dⅡCT6 Gb. It is suitable for corrosion-resistant and high-temperature applications.

2. Stable And Reliable

Our products utilize high-quality modules, including the power supply, in their circuit design. Key components are sourced with highly stable and reliable components, making them a direct replacement for international brand instruments.

3. Intelligent Technology

Ultrasonic intelligent technology software performs intelligent echo analysis, eliminating the need for any debugging or other special steps. This technology features dynamic thinking and analysis.

4. High Accuracy

Our proprietary ultrasonic intelligent technology significantly improves the accuracy of ultrasonic level meters, achieving a level accuracy of 0.3% and resisting various interference waves.

5. Low Failure Rate, Easy Installation, And Easy Maintenance

Ultrasonic level meters are non-contact instruments that do not come into direct contact with the liquid, resulting in a low failure rate. The instruments offer a variety of mounting options, and users can perform their own calibration.

6. Customization Available

A variety of signal output options are available, including 4-20mA, RS485 communication, and relay output.

7. Versatile Protection

The explosion-proof ultrasonic level meter has an IP65 protection rating; all input and output lines are protected against lightning and short circuits.

Featured Application Scenarios

Sino-Inst ultrasonic level meters have numerous application scenarios, but when selecting a model, it’s crucial to understand the medium being measured. Once the medium is determined, it’s time to decide whether explosion-proof or non-explosion-proof is required. Explosion-proof types are categorized as intrinsically safe and explosion-proof. Explosion-proof refers to a stainless steel housing for the components; intrinsically safe explosion-proof refers to a completely sealed enclosure, isolating any explosive gases outside the chamber.

So, when would an explosion-proof ultrasonic level meter be used?

1. The measured medium is flammable and explosive, mostly liquids and gases. Examples include gasoline, alcohol, toluene, xylene, acetone, biogas, gas, hydrogen, and most organic compounds. Solids include metallic magnesium, metallic sodium, and yellow phosphorus.

2. Underground mines, including coal mines and iron mines. Almost all mines require explosion-proof technology.

3. Dusty environments. For example, woodworking workshops and coal processing workshops. Dust concentrations reaching a certain level can also cause explosions.

4. Although there are no directly flammable or explosive liquids or gases, explosion-proof ultrasonic level meters and ultrasonic material level meters are still needed in explosion-proof areas. For example: sewage treatment plants of oil refineries and fire water pools in oil tank areas.

Explosion-proof ultrasonic level meters are not suitable for the following measurement conditions:

- Foam and floating debris on the liquid surface;

- Highly volatile liquids and locations with large amounts of water vapor;

- Liquids prone to crystallization;

- Ambient conditions such as strong voltage, current, electromagnetic field, or vibration interference;

- Direct wind and sunlight;

- Locations with agitators;

After reading the above measurement media and scenarios, I believe you know whether you need to use explosion-proof or non-explosion-proof ultrasonic level meter. If you still don’t understand, you can consult our professionals.

More Solutions For Level Measurement

- Case – Liquid Nitrogen Level Measurement

- Magnetic Level Measurement:

- Different Solutions for Fluid Level Measurement

- Float Type Level Transmitters for Continuous Level Measurement

- All-inclusive Guide To Bin Level Measurement Systems

- Tank Level Measurement with Pressure Transmitters/DP Transmitters

- Hydrostatic Level Measurement-Liquid Level Measurement with Pressure Sensors

- Difference Between Radar and Guided Wave Radar Level Transmitter

- Industrial Ultrasonic Level Transmitters | Non-contact Level Measurement

- Submersible Pressure Transducers for Liquid Pressure and Level Measurement

- Different Diesel Level Sensors for Diesel Tank Level Measurement

- Typical Ultrasonic Level Sensor Applications and Advantages

- Dry Materials-Bulk Solids-Powder Level Sensors Guide

Summary

Explosion-proof ultrasonic level meters are the preferred solution for level measurement in hazardous environments such as the petroleum, chemical, and mining industries. Sino-Inst’s explosion-proof ultrasonic level meters are both robust and provide accurate measurement in harsh environments, earning them a strong reputation among customers both domestically and internationally.

Sino-Inst’s explosion-proof ultrasonic level meters are certified for explosion-proof performance. Choosing a product with this certification not only ensures production safety but also protects your health. If you have any level measurement needs, especially those in harsh environments, please contact us.

-1.jpg)