Bin Level Indicators and Controllers can monitor the changes of materials in the silo in real time and accurately. Choosing the right Bin Level Indicators and Controllers can achieve efficient production planning and ensure the reliable transportation of finished products.

In the industrial production process, a variety of liquid, solid, powder and other raw materials need to be scheduled and stored. Reliable silo level measurement needs to consider many factors. Including different solid density, abrasive media, severe dust and explosion-proof requirements.

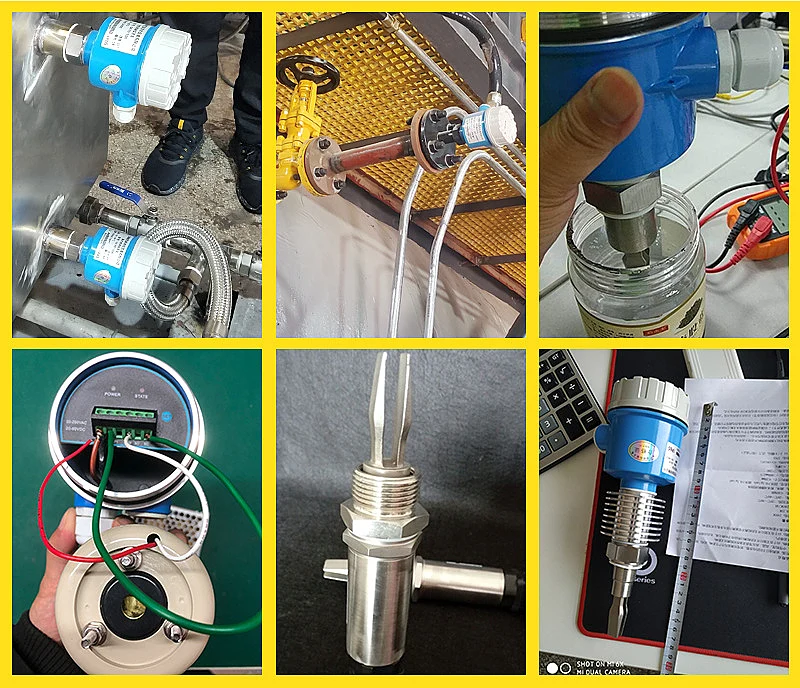

Featured Bin Level Indicators and Controllers

Importance of Bin Level Measurement

Mainly stems from the following aspects:

- First, the unstable material supply leads to large fluctuations in the material inventory in the silo;

- Second, the production demand changes rapidly, and the timeliness of material supply is required to be high;

- Third, the inaccuracy and lag of manual inspection make it difficult to detect and deal with material level problems in time.

These factors work together to make silo material level management a complex and arduous task.

The impact of the material level crisis on production cannot be ignored. When there is insufficient material in the silo, it will cause the production line to be interrupted, affecting production efficiency and delivery time. When there is too much material, it may cause accidents such as full silo and overflow, resulting in material waste and environmental pollution.

Bin Level Indicators Vs Controllers

Bin Level Indicators can also be called level meters or level transmitters. They are generally used to measure the material level continuously. They also have local digital displays. And they can output 4-20mA signals.

For example, our commonly used radar level meters, ultrasonic level meters, etc.

Bin Level Controllers are also called level switches. They are mainly used to alarm when the material level reaches the preset height and output switch control information. This is a point measurement.

For example, our tuning fork level switch, rotary paddle level switch, etc.

Different characteristics of material level measurement, liquid level measurement and interface measurement

Material level measurement, liquid level measurement and interface measurement each have their own characteristics. Generally speaking, in practical applications, their different characteristics are mainly manifested in the following aspects:

I. Characteristics of material level measurement

In material level measurement, affected by the characteristics of the material, it often has the following characteristics:

- When feeding and discharging materials, the material will rub or impact with the measuring element, and will also hang on the measuring element.

- When feeding and discharging materials, there will be retention areas, bridges and accumulation of materials on the silo wall in the silo.

- When naturally stacked, the material surface will have a certain repose angle, which varies with the particle size, specific gravity, surface fluidity of the material, and is greatly affected by whether the material is added or discharged, the method of feeding, and the position of the feeding (discharging) port.

II. Characteristics of liquid level measurement

Different liquid properties have different characteristics of liquid level measurement:

- Large storage tanks will have uneven temperature and density in various parts of the storage tank.

- In liquid level measurement, vacuum, high pressure, high temperature, or high temperature and high pressure exist at the same time.

- When measuring the liquid level, the various corrosive media measured have different corrosiveness.

- During the process, the liquid surface will fluctuate, boil, foam, contain suspended particles, contain bubbles, high viscosity and other different working conditions.

III. Characteristics of interface measurement

When measuring the position of the liquid-liquid and liquid-solid interface, sometimes the interface will not be obvious and there will be a turbid layer.

The above three different level measurements have different characteristics and performances, and have different requirements for level measurement instruments. Understanding these different characteristics will help us better select models.

Benefits of Bin level measurement system

The level measurement system can achieve real-time monitoring and accurate measurement of the material height inside the silo by adopting advanced level detectors and intelligent algorithms. Whether it is solid particles, powders or liquids, the level measurement system can flexibly select the appropriate detection method according to the characteristics of the material and the structure of the silo to ensure the accuracy of the measurement data.

More Featured Level Measurement Solutions

- Dry Materials-Bulk Solids-Powder Level Sensors Guide

- Role of Hydrostatic Level Transmitters In Well Water Level Monitoring Process

- Water Level Pressure Transducers

- Typical Ultrasonic Level Sensor Applications and Advantages

- Different Diesel Level Sensors for Diesel Tank Level Measurement

- Submersible Pressure Transducers for Liquid Pressure and Level Measurement

- Explosion Proof Pressure Transducers- Intrinsically Safe – ExdIICT6-ExiaIICT6 Ga

- Liquid Level Controllers and Switches for Industrial Tanks

- Industrial Ultrasonic Level Transmitters | Non-contact Level Measurement

Through real-time monitoring of material level changes, accurate measurement and data analysis, as well as automated and intelligent management, Bin Level Indicators and Controllers not only improve production efficiency and product quality, but also provide a strong guarantee for stable production.

Sino-Inst produces and supplies various types of Bin Level Indicators and Controllers. If you need to purchase or have related technical questions, please feel free to contact us.

-1.jpg)