When selecting a pressure transmitter, you will inevitably encounter a very important parameter: temperature. This includes operating (medium) temperature and ambient temperature. This is because it involves an important manufacturing process that our factory performs: temperature compensation of the pressure transmitter.

What is Temperature Compensation for Pressure Transmitters?

Simply put, temperature compensation for pressure transmitters eliminates temperature drift in the measurement results within a certain temperature range.

In a pressure transmitter, under constant measurement conditions, the output signal will drift with changes in temperature. To minimize this phenomenon, we use certain algorithms to correct the output results, aiming to eliminate the influence of temperature changes on the sensor’s output signal within a certain range. This entire process is temperature compensation.

Why Need Temperature Compensation?

Before understanding temperature compensation, let’s look at what operating temperature and ambient temperature are.

Operating Temperature

Operating temperature is the temperature of the medium that the pressure sensor is in contact with. For example, measuring the pressure of nitrogen at 30℃, or measuring the pressure of liquid nitrogen at -196℃.

Pressure transmitters can measure a wide range of media temperatures, from -200℃ to 1200℃, and pressure transmitters can be customized for these temperatures.

Ambient Temperature

Ambient temperature refers to the temperature of the environment surrounding the pressure transmitter’s casing and main body. Most of the time, it’s the air temperature to which the casing is exposed. The circuit board inside the pressure transmitter’s main body, as well as the materials of the cable connectors, require the ambient temperature of the pressure transmitter’s main body to be within -20℃ to 85℃.

The Importance of Temperature Compensation

The static characteristics of most pressure sensors are closely related to temperature. In practical work, due to the large changes in the ambient temperature of the sensor and the relatively large thermal output caused by temperature changes, this will lead to significant measurement errors, thereby affecting the static characteristics of the pressure sensor.

Therefore, measures must be taken in the design to reduce or eliminate the measurement effects caused by temperature changes. Sometimes, the temperature compensation parameters are even more important than the accuracy rating. Of course, this mainly depends on the working conditions on site.

When choosing a pressure transmitter, be sure to pay attention to the temperature compensation parameters. This is especially important in working conditions with large temperature variations.

For example, consider a pressure sensor installed outdoors: in winter, the ambient temperature may drop to -40°C, but near a certain piece of equipment, the temperature might rise to 70°C, resulting in a significant temperature difference.

Similarly, flow meters used in industrial process measurements also require temperature and pressure compensation.

How is Temperature Compensation Performed for Pressure Transmitters?

Temperature compensation technology is divided into two main categories: hardware compensation and software compensation. Both utilize a hybrid mode of “physical correction + intelligent algorithm” to achieve wide-temperature range stability:

Hardware compensation: Fast-response physical correction

Thermistor compensation: A negative temperature coefficient thermistor is integrated into the sensor circuit. Its resistance decreases as the temperature rises. A voltage divider circuit adjusts the compensation voltage to correct zero-point drift.

Bimetallic strip compensation: A mechanical structure is designed using the difference in thermal expansion coefficients of two metals to drive the displacement of sensor components, offsetting the effect of temperature on sensitivity.

Filling fluid optimization: For high-temperature scenarios, the amount of filling fluid is reduced to lower thermal expansion pressure; for low-temperature scenarios, the amount of filling fluid is increased to prevent diaphragm damage due to vacuum conditions.

Software compensation: High-precision intelligent algorithm correction

Microprocessor dynamic calibration: A built-in temperature sensor continuously collects ambient temperature data. Combined with pre-stored temperature-pressure calibration curves, an interpolation algorithm dynamically corrects the output signal. For example, a polynomial fitting algorithm is used to input the original temperature and pressure signals into a multivariate function, outputting an accurately compensated pressure value.

HART protocol communication support: Supports remote temperature parameter writing and calibration data updates, adapting to different media and working conditions, enabling self-diagnosis and self-calibration of the device.

Sino-Inst Pressure Transmitter Temperature Compensation

Sino-Inst pressure transmitters/DP transmitters have a temperature compensation range of -40~85°C, meaning that the effects of temperature on the pressure sensor are corrected within this temperature range.

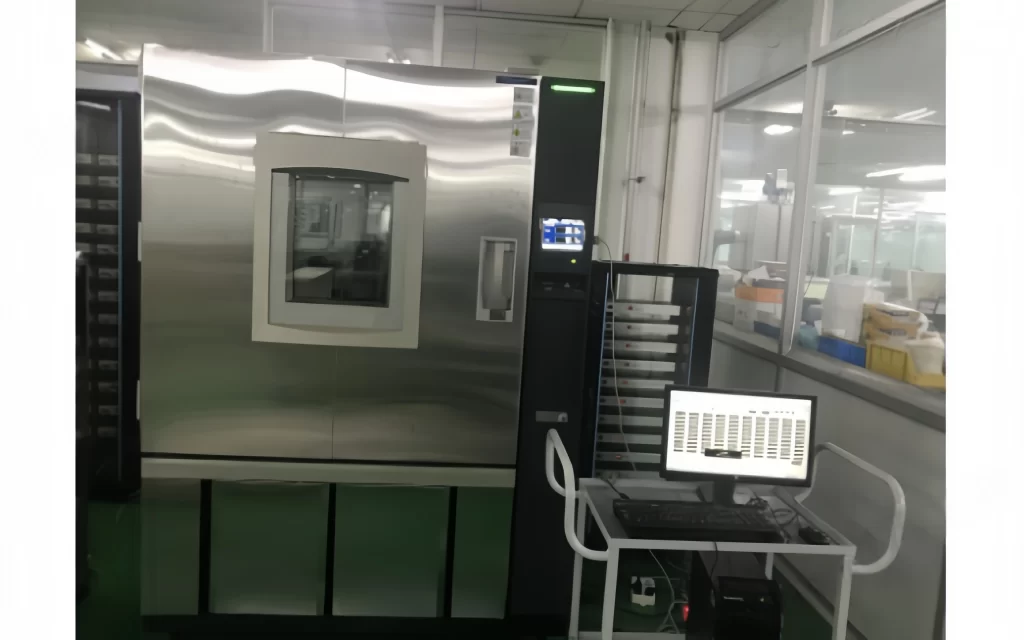

Sino-Inst uses a multi-point temperature compensation system during the manufacturing of its pressure transmitters/DP transmitters. Each pressure transmitter has some temperature offset error. Through our matrix-based multi-point temperature compensation system, we perform temperature compensation on each pressure transmitter within the range of -40°C to 85°C, ensuring that our pressure transmitters achieve excellent measurement accuracy at both high and low temperatures.

Pressure Measurement at Extreme Temperatures

Although the standard operating temperature range for pressure sensors is -20°C to 85°C, many measurement conditions exceed this temperature range. In addition to temperature compensation, we can mitigate the effects of temperature on pressure sensors by adding temperature buffering components. Examples include using high-temperature silicone oil, heat sinks, pressure tubes, and remote diaphragms. Please refer to our solutions and case studies for extreme temperature pressure measurement:

High Temperature Pressure Transducers & Cooling Elements

High-Temperature Media Pressure Measurement Case: 900-1200°C

Case-Liquid Oxygen Pressure Measurement

What Are Diaphragm Seal Systems in Pressure Measurement? and Types

Customized Case: High Temperature and High Pressure Pressure Measurement -100MPa-700℃

Industrial Hydrogen Pressure Transmitters/Transducers

Liquid Nitrogen Pressure Measurement – Pipeline and Tank

High Temperature Pressure Transducers|800℃~1200℃

As a professional pressure transmitter manufacturer, Sino-Inst has over 10 years of experience in the production and R&D of pressure transmitters. We are experts in pressure transmitter accuracy and temperature compensation technology.

We customize pressure measurement solutions for users in various industries at different temperatures. Please feel free to contact our sales engineers!

-1.jpg)