In many industrial and scientific applications, accurate measurement of low pressure is crucial for maintaining safety, performance, and efficiency. Low pressure transmitters/Transducers measure gauge pressure, differential pressure, and absolute pressure below 1 bar. They are ideal for cleanroom, HVAC, and air pollution control applications.

At Sino-Inst, we specialize in manufacturing high-quality low-pressure transmitters. These transmitters are meticulously designed and provide a 4-20mA output. They are capable of adapting to a wide range of operating conditions.

What Is a Low-Pressure Transmitter?

Low-pressure transmitters can convert low gas or liquid pressure into readable and recordable electrical signals. They are specifically designed for measuring low pressure levels in systems. They can measure pressures as low as a few Pascals.

Low-pressure transmitters can measure pressures or differential pressures as low as 1 mbar. They are commonly used in HVAC systems, medical applications, and aerospace fields.

Key Features of Low-Pressure Transmitters

- High Sensitivity. Low-pressure transmitters are compact, have a fast response time, and high sensitivity.

- Simple Structure. Low-pressure transmitters have a simple structure, low cost, and high reliability. They are suitable for mechanical pressure measurement in general industrial environments.

- High Accuracy. The accuracy range of low-pressure transmitters is between ±0.075%FS and ±0.5%FS. High-precision models can reach 0.075%FS.

- Strong Anti-interference. Some low-pressure transmitters use a two-wire 4-20mA output. They have strong anti-interference capabilities and long transmission distances.

- Voltage Conversion. Converts high input voltage to a lower, safer output voltage (e.g., 12V, 24V AC/DC).

- High Energy Efficiency. Lower power consumption reduces energy costs and environmental impact.

- High Durability. High IP (Ingress Protection) rating for effective moisture and dust protection in outdoor environments.

Working Principle of Low-Pressure Transmitters

The working principle of a low-pressure transmitter involves measuring low-pressure physical quantities and converting them into standard electrical signal outputs. Low-pressure transmitters utilize flexible diaphragms equipped with sensors to measure minute deformations.

The sensing section contains a thin, flexible diaphragm. When pressure is applied, the diaphragm bends. This bending is extremely minute. A piezoresistive pressure sensor strain gauge or optical detector can detect it.

After comparing the pressure or temperature with the zero signal, the difference is amplified by an amplifier. The output signal is then converted into a feedback signal via the feedback section, forming a closed-loop control system, and ultimately outputs a standard signal.

Featured Film

Bulky sensors cannot obtain accurate low-range data. To achieve high sensitivity in low-pressure sensors, we utilize large-diameter, ultra-thin diaphragms. This design maximizes the surface area, allowing even the weakest airflow to produce measurable deformation. This ensures that your leak detection pressure sensor can detect problems before they escalate into disasters.

Key Sensor Technologies Compared

Not all sensors are built the same. Depending on your application, we usually rely on three main technologies:

- Piezoresistive Low Pressure Transmitter: These use strain gauges bonded to the diaphragm. They are rugged and offer great response times, making them the standard workhorse for general industrial applications.

- Capacitive Low Pressure Sensor : This is often the gold standard for ultra-low ranges (draft ranges). It measures the change in capacitance between the diaphragm and a fixed plate. They are incredibly stable and resistant to overpressure—perfect for critical cleanroom pressure monitoring.

- Piezoelectric: These are less common for static pressure but excellent for measuring dynamic pressure changes or spikes.

Typical Low Pressure Transmitters

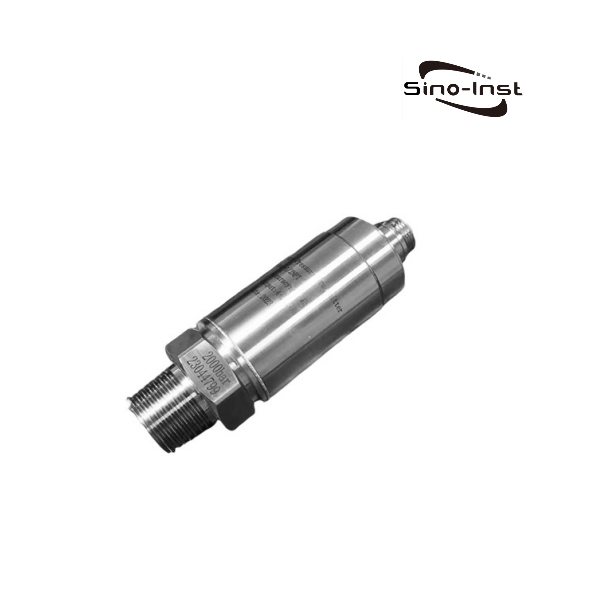

Sino-Inst supply a variety of high-accuracy low-pressure transducers, supporting customized parameters and OEM services.

Gauge Pressure Transmitter

A gauge pressure transmitter is a sensor that measures the difference between the pressure of a gas or liquid and the local atmospheric pressure. Gauge pressure transmitters have a wide pressure range. They can measure micro-differential pressures from 0.1 to 1.5 kPa up to high pressures from 0 to 600 bar.

Unlike absolute pressure transmitters, gauge pressure transmitters reference atmospheric pressure. Structurally, they must be connected to the external atmosphere. Common types include piezoresistive and capacitive designs, offering high accuracy and a broad measurement range.

Piezoresistive Pressure Transmitter

Piezoresistive pressure transmitters utilize the piezoresistive effect to measure gas or liquid pressure. The measurement range spans from -100 kPa to 900 MPa. Accuracy grades typically reach ±0.5%. High-precision models achieve accuracy as high as ±0.075%.

Piezoresistive pressure transmitters feature high accuracy, rapid response, and compact construction. They are widely used in petroleum, chemical, medical, and other industries.

Capacitive Sensor

A capacitive pressure transmitter is a device that converts pressure parameters into standard electrical signals. The measuring diaphragm and electrodes on both sides of the insulating plates form a capacitor. When pressure changes, diaphragm displacement causes a change in capacitance. This is then converted and amplified by the circuit to output standard signals such as 4–20 mA.

Capacitive pressure transmitters achieve accuracy up to ±0.05%. Operating temperature range: -40°C to 85°C. Withstand static pressure up to 32 MPa. These transmitters offer excellent stability and strong interference resistance, making them suitable for long-term monitoring applications.

Differential Pressure Transmitter

A differential pressure transmitter measures the pressure difference between two points. Standard differential pressure transmitters have a pressure range of 0-1.3 to 6890 kPa, with a maximum range of 0-6890 kPa or 42 MPa. The static pressure tolerance range is 4.1 MPa to 32 MPa. It outputs a standard signal (e.g., 4-20mA, 0-5V).

Differential pressure transmitters are primarily used to measure the pressure difference, pressure, and negative pressure of liquids, gases, and steam. They can also measure liquid levels in open or pressurized vessels.

Absolute Pressure Transmitter

Absolute pressure transmitters are used to measure the absolute pressure within industrial equipment. Their measurement reference is absolute vacuum. The pressure range of absolute pressure transmitters is from 0 to 0.1 kPa to 0 to 40 MPa. Accuracy can reach up to 0.05%. Core sensing technologies include capacitive, resonant, and single-crystal silicon types.

Absolute pressure transmitters are used to measure the true pressure value of gases or liquids. They are unaffected by changes in external atmospheric pressure. They are widely used in petrochemical, power generation, aerospace, smart building, and other fields.

Common Applications of Low-Pressure Transmitters

HVAC and Building Automation

- Filter Monitoring. Eliminate guesswork about when to replace filters. HVAC differential pressure transmitters measure the pressure drop across the filter.

- Cleanroom Pressure Monitoring. In pharmaceutical manufacturing or semiconductor labs, maintaining positive pressure prevents contaminants from entering. Low-pressure diaphragm sensors ensure cleanroom pressure remains within specified limits.

- Static Pressure Ducting. Regulating airflow in VAV (Variable Air Volume) boxes requires precise static pressure readings to control fan speed and damper settings.

Medical and Laboratory Equipment

- Ventilators and spirometers. These devices rely on ultra-low pressure sensors to monitor patients’ breathing. The sensors can detect very subtle pressure changes during the respiratory cycle.

- Isolation wards. Similar to cleanrooms, hospitals use cleanroom pressure monitoring to contain infectious diseases within negative-pressure isolation wards.

Industrial Process Control

- Leak Detection. Leak detection pressure sensors are used to check the integrity of sealed components. They work by monitoring pressure decay. Even a slight decrease in pressure over time indicates a micro-leak.

- Tank Level Monitoring. We use 4-20mA pressure transmitters with millibar range. They measure the liquid level in vented tanks using hydrostatic pressure, or the level of corrosive liquids using a bubbling system.

- Burner Control. Monitoring the air-fuel ratio in industrial burners requires measuring low-pressure gas flow.

Environmental and Vacuum Technology

- Vacuum Systems. Standard sensors fail in demanding vacuum applications. In pick-and-place machines or vacuum drying processes, specialized vacuum pressure transmitters are needed to monitor the suction lines.

- Emission Monitoring. Flue gas monitoring typically involves differential pressure measurement for flow rate. If explosive gases are present, robust ATEX-certified low-pressure transmitters are required.

How to Choose the Right Low Pressure Transmitter?

Choosing the right low-pressure transmitter is not simply a matter of selecting a model that fits the pipe. More importantly, it’s about matching the sensor’s characteristics to your specific process requirements. Over the years, we’ve seen too many systems with seemingly good specifications that fail in real-world applications.

Here’s a simple checklist I recommend to ensure you get the right size:

- Determine the pressure type. Determine whether you need a low-range gauge pressure sensor or a low-range differential pressure sensor.

- Select the range precisely. Do not over-specify the range. If your process has a peak pressure of 10 mbar, purchasing a 100 mbar sensor will severely impact accuracy. You should choose an ultra-low pressure sensor with a range that matches your maximum operating pressure.

- Output compatibility. Does your control system require a standard 4-20mA pressure transmitter output, a 0-10V output, or digital communication like a HART protocol pressure transmitter?

- Environmental rating. For hazardous areas, you must verify the relevant certifications. In explosive gas or dust environments, an ATEX low-pressure transmitter is essential for safety.

- Drift requirements. If the sensor is located in a difficult-to-access locati0n, prioritize zero-drift compensation to reduce maintenance.

FAQ

More Pressure Measurement Solutions

Water Pressure Transducers – 2026 Guide With Product List

Water Level Pressure Transducers

G Thread vs NPT for Pressure Transmitters

What is a Dynamic Pressure Sensor? Vs. Static

Case – High Frequency Dynamic Pressure Sensor: 0-200 kHz

High Temperature Pressure Transducers & Cooling Elements

What Is a Pressure Switch? Read Before Buy and Use

In many applications, maintaining low pressure is crucial. Low-pressure transmitters are essential instruments. These low pressure transmitters/Transducers utilize advanced sensor technology and robust construction. They are specifically designed for the precise measurement of gauge pressure, differential pressure, and absolute pressure far below 1 bar.

Sino-Inst manufactures and supplies a full range of pressure sensors. We offer a variety of models and can customize solutions to meet the specific needs of different applications. This includes not only low-pressure sensors but also high-pressure sensors, sensors with special threads, and sensors made from special materials.

If you need to purchase low pressure sensors or have any related technical questions, please contact our engineers!

-1.jpg)