What is a Radar Level Sensor?

A radar level sensor is an instrument that uses microwave echo ranging to measure liquid levels non-contactly. It can measure both liquid and solid levels and is widely used in river level measurement, container, storage tank, and silo level monitoring. Measurement accuracy is up to ±1mm, and the measurement range can reach 150m.

How Does Radar Level Sensor Work?

Radar level sensors determine the liquid level by emitting electromagnetic waves and receiving reflected signals, measuring the distance between the liquid surface and the sensor.

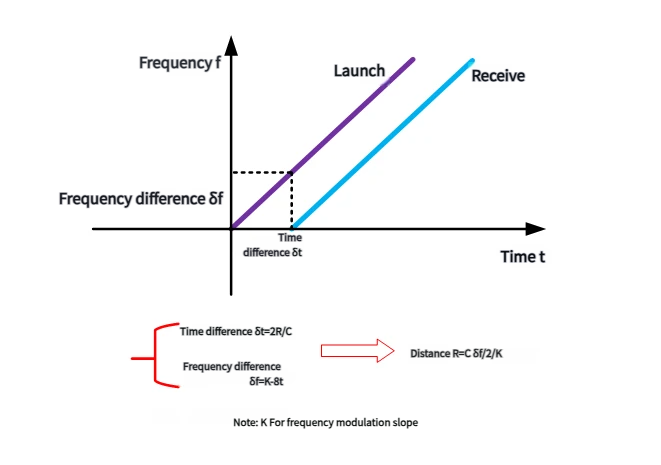

Electromagnetic waves are reflected by a medium and received by radar. The frequency difference δf between the received and transmitted signals is proportional to the distance R from the medium surface:

R = C (velocity) * δf (frequency difference) / 2 / K (modulation slope).

Since the speed of light C and the modulation slope K are known, the frequency difference δf can be calculated to obtain the distance R from the radar installation location to the material surface. Then, by subtracting the spatial distance from the radar to the material surface (referred to as air height) from the known total height of the tank, the height of the material level can be obtained.

When to Use Radar Level Sensors?

Whether it’s liquids, solids, or slurries, radar level sensors are highly adaptable. They can provide stable, continuous level monitoring in special operating conditions such as high temperature and pressure, dusty environments, steam, highly viscous media, corrosive media, and agitation.

Radar Level Sensor for Tanks

Radar level sensors offer superior penetration and measurement accuracy, making them the perfect choice for tank level measurement. They operate normally even in environments with adhesion and condensation.

In industries such as petroleum and chemical manufacturing, high-temperature and high-pressure environments are frequently encountered. The 80G radar level sensor utilizes special materials and structural design to operate stably under these conditions. Examples include reactors and autoclaves in oil refineries.

In containers requiring agitation, level measurement can be affected by the agitator. Traditional level measurement equipment may fail to accurately measure the level due to agitator interference. The 80G radar level sensor has strong anti-interference capabilities, enabling accurate level measurement in agitated containers.

Radar Level Sensor for Solids

In some industrial production processes, such as cement, coal, and flour milling, large amounts of dust are generated. This dust can cause blockages and damage to traditional level measurement equipment. The 80G radar level sensor uses high-frequency electromagnetic wave technology, which can penetrate dust and accurately measure the level.

For example, in cement plant silos and coal storage yards, 80G radar level sensors can effectively measure the liquid level of materials.

Radar Level Sensor for Water

Radar level sensors can monitor large water levels at a lower cost. Radar level sensors do not need to be in contact with the water surface, making them ideal for use in complex or harsh environments. For example, floating debris, air bubbles, and sludge will not affect the measurement results. Furthermore, radar level sensors are highly adaptable to environments with large water surface fluctuations and inclement weather.

Featured Radar Level Sensors

80G Radar Level Sensor

- Millimeter-wave radar with measurement accuracy up to ±1mm and a minimum blind zone of 0.05m.

- Smaller antenna size accommodates a wider range of industrial measurement scenarios.

- Multiple lens antenna options deliver narrower beam angles, more focused energy, and stronger echo signals, offering higher reliability than other radar products under equivalent industrial conditions.

- Superior penetration capability ensures reliable operation even in conditions involving buildup or condensation.

- Wider dynamic signal range enables more stable measurement of low-dielectric-constant materials.

- Multiple measurement modes, with a radar response time of 200ms in fast measurement mode.

Low Cost Radar Level Sensor

- Better price!

- Electromagnetic wave emission angle less than 3°, ideal for narrow spaces or guided wave pipe measurements;

- Measuring range up to 120M, suitable for ultra-large storage tanks;

- The product’s measurement blind zone is within 7-8 cm, making it suitable for small storage tanks;

- It offers extremely high measurement accuracy, making it suitable for high-precision metering-grade applications;

- It incorporates advanced echo processing algorithms and extensive empirical data for various operating conditions, providing unique advantages over comparable products in extremely harsh environments such as heavy dust or steam; or in special process storage tanks with agitators, heating rods, and other features.

Radar Water Level Sensor

- Millimeter-wave RF chips enable more compact RF architectures, higher signal-to-noise ratios, and smaller blind zones.

- The 5GHz operating bandwidth enables higher measurement resolution and accuracy.

- With a minimum antenna beam angle of 6°, interference from the installation environment has minimal impact on the instrument, and installation is more convenient.

- Integrated lens design, compact form factor.

- Display controls and level gauge feature a separate design, allowing for customization.

- Low-power operation with a service life exceeding 3 years.

- Maximum product range reaches 85m, with a blind zone of 10cm.

Selection Case

Asphalt, a viscous byproduct of crude oil refining, is a high-viscosity organic liquid. It serves as a binder for asphalt used in road, bridge, and waterproofing applications.

A customer at an asphalt mixing plant contacted us requiring asphalt level monitoring. Three main issues needed to be considered:

- The temperature range of asphalt tanks is typically between 140°C and 180°C.

- Asphalt fumes condense upon cooling in air.

- Asphalt volatilization produces asphalt fumes, which are corrosive.

Based on the customer’s comprehensive operating parameters, we selected the 80GHz FMCW Radar Level Snesor, specifically designed for challenging applications such as asphalt tanks. With its narrow beam angle and high-frequency signal, it provides continuous and reliable level measurement even under interference from steam, condensate, or tank obstructions.

- Radar Level Meter

- Model: FMW13G

- Measurement Medium: Asphalt

- Measurement Range: 13.716 meters

- Atmospheric Pressure

- Medium Temperature: 175°C

- Signal Output: 4-20mA

- Antenna Size: 76mm Lens Antenna

- Antenna Material: PEEK

- Accuracy: ±2mm

- Protection Rating: IP67

- Center Frequency: 80GHz

- Emission Angle: 6°

- DN80 ASME Standard 150# Flange Mount

- 24VDC

- Signal Output: 4-20mA

More About Radar Level Measurement

Radar level sensors are widely used in various production industries such as chemical and petroleum due to their high measurement accuracy and media compatibility. In addition to radar level sensors, Sino-Inst also supports customized level measurement solutions for other types of liquid levels. Please feel free to contact us!

-1.jpg)