In industrial applications, there are many methods for measuring and monitoring liquid levels. For measuring liquid levels in open and pressurized tanks, engineers typically choose differential pressure level transmitters. This is a well-established technology. The liquid level is calculated by measuring the pressure difference between the liquid and gas phases of a fluid within a closed tank. It outputs a standard signal (e.g., 4~20mA, 0~5V).

Differential pressure transmitters can also be used to measure differential pressure, pressure, and negative pressure of liquids and gases. They can also measure density. When equipped with a throttling device, they can measure the flow rate of liquids, gases, or vapors.

Understanding Differential Pressure Level Transmitters

A differential pressure level transmitter is a device that determines the liquid level by measuring the pressure difference between two points in a system.

Differential pressure level sensors have the advantages of simple structure and easy installation. They are also suitable for toxic, corrosive, or high-pressure substances. Furthermore, they employ non-contact measurement, providing reliable data, especially in situations involving stirring or foaming.

What is the Difference Between a Pressure Transmitter and a Differential Pressure Transmitter?

Pressure transmitters measure the pressure value at a single point. Differential pressure transmitters measure the pressure difference between two points. This is the core difference between the two.

| Feature | Pressure Transmitter | Differential Pressure Transmitter |

| Measurement Principle | Pressure transmitters measure the absolute pressure or gauge pressure at a single point in a system. | Differential pressure transmitters measure the pressure difference between two points. |

| Interface Design | Only one pressure interface. | Two pressure interfaces. |

| Structure | Composed of a pressure sensor, amplifier circuit, and supporting components. | Composed of a load cell, module circuit, display head, housing, and process connectors. |

| Output | Pressure transmitter outputs absolute pressure value (unit: MPa). | Differential pressure transmitter outputs relative pressure difference (unit: Pa). |

| Measurement Range | Pressure transmitters typically have a wider measurement range, covering absolute pressure or gauge pressure. | Differential pressure transmitters are mainly used to measure the pressure difference between two locations, with a relatively concentrated range. |

| Application Scenarios | Suitable for single-point pressure monitoring. | Suitable for liquid level calculation, flow monitoring, and system maintenance. |

How Differential Pressure Level Transmitters Work

Differential pressure level transmitters operate based on Pascal’s Law. When the liquid level changes, the pressure at the bottom increases, creating a pressure difference. The sensor converts this pressure difference into an electrical signal output.

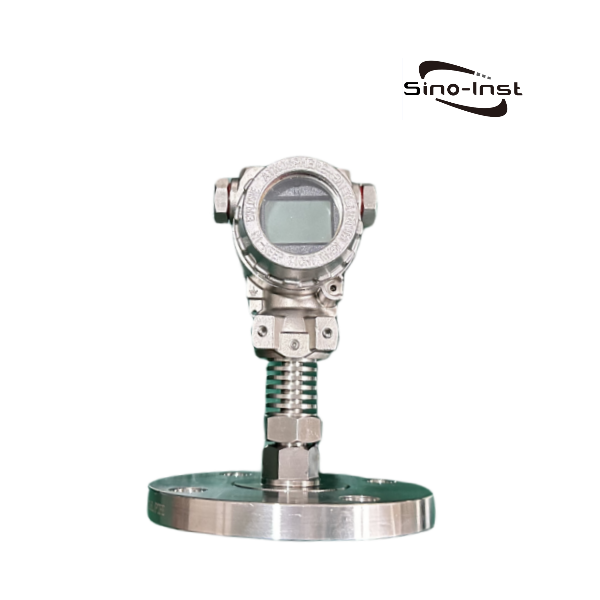

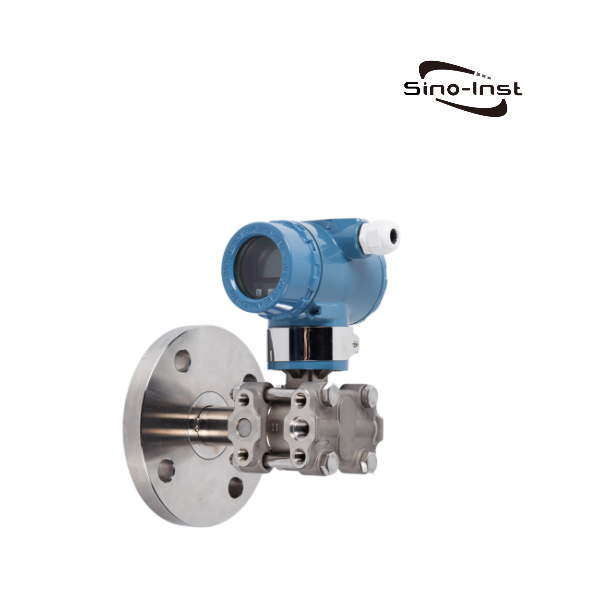

A differential pressure level transmitter typically consists of two parts: a differential pressure sensor and a transmitter. One pressure tap is installed at the bottom of the container. The other pressure tap is installed at the liquid level or the top of the container.

Differential pressure level transmitters can be used in conjunction with primary flow elements to measure flow rate, such as orifice plates or venturi tubes. The pressure difference generated by these devices is proportional to the flow rate.

As fluid passes through the primary element, velocity increases and pressure decreases. Greater flow velocity results in a larger pressure differential. The transmitter measures the difference (ΔP) between the two pressures. This differential pressure is proportional to the square of the flow rate (ΔP ∝ Q²).

The advantage of differential pressure flow measurement is the absence of moving parts in both the transmitter and the primary element. This fixed design eliminates mechanical wear and reduces maintenance requirements. This robust measurement principle delivers exceptional service life and reliable operation.

Types of Differential Pressure Level Transmitters

Capacitive Differential Pressure Transmitter

Capacitive differential pressure transmitters use capacitive sensors to convert changes in capacitance into electrical signals. This technology can be used to measure pressure, flow rate, and density.

A capacitive differential pressure transmitter uses a flexible diaphragm located between two conductive plates. When the pressure on both sides changes, the diaphragm displaces. This displacement is proportional to the pressure difference. The capacitance also changes. The electronic circuitry converts this capacitance change into a 4-20mA DC two-wire current signal.

Diffused Silicon Differential Pressure Transmitters

Diffused silicon differential pressure transmitters utilize diffused silicon sensing technology. They employ a silicon diaphragm to sense pressure and convert it into an electrical signal using the piezoresistive effect. This allows them to measure the difference between two pressure points. The pressure to be measured is applied to two silicon wafers on either side; the minute change in resistance within the wafers is converted into an electrical signal output.

Diffused silicon differential pressure transmitters are made of stainless steel or other durable materials. They can withstand harsh industrial environments . So, they are widely used in oil and gas, chemical processing, medical equipment, and aerospace.

Monocrystalline Silicon Differential Pressure Transmitter

Single-crystal silicon differential pressure transmitters use high-purity single-crystal silicon sensor chips to measure the pressure difference between two points.

Single-crystal silicon differential pressure transmitters utilize the piezoresistive effect of single-crystal silicon. When single-crystal silicon material is subjected to axial stress, its resistivity changes.

Single-crystal silicon differential pressure transmitters are designed for high accuracy and high stability. They are suitable for various fields, from process control to aerospace.

Applications of Differential Pressure Level Transmitters

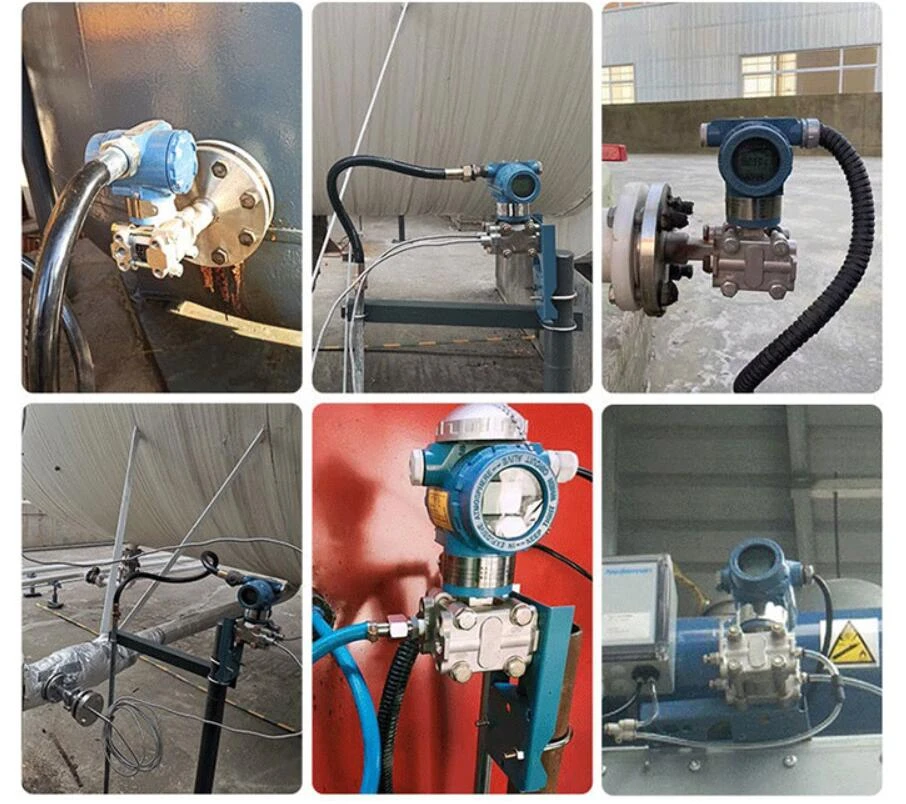

Differential pressure level transmitters are commonly used in the petrochemical industry. Petrochemical plants are typically flammable, explosive, and hazardous. Therefore, accurately monitoring the process parameters within these plants is of paramount importance.

Liquid level is one of the most important parameters in the production process. There are many types of level instruments with remote transmission capabilities. Such as radar level gauges, ultrasonic level gauges, and differential pressure level gauges. Differential pressure level transmitters are one of the most widely used types of level instruments.

Differential pressure level transmitters are suitable for the following operating conditions:

Special Media Handling

Differential pressure level transmitters are suitable for high-temperature, viscous media containing solid particles. Examples include reaction vessels and storage tanks in petrochemical production. This avoids problems related to pressure line leakage or isolation fluid replenishment.

Industrial Control Scenarios

Differential pressure level transmitters are commonly used in metallurgy, mining, shipbuilding, power, and environmental protection industries. They feature anti-clogging design and temperature compensation.

Hygienic Requirements Scenarios

In industries requiring sanitary cleanliness, their contact medium components are washable. This prevents cross-contamination.

High-Temperature and High-Pressure Environments

Differential pressure level transmitters utilize Hastelloy materials and capillary isolation technology. They withstand temperatures ranging from 40°C to 400°C.

Recommendations for Diaphragm and Filler Fluid Selection in Differential Pressure Level Transmitters

Diaphragm Material Selection

Common diaphragm materials include 316LSS, Hastelloy, Monel, and tantalum. Unless there are special requirements, we usually choose 316LSS stainless steel. This material balances durability and economy. However, special working conditions and media require special consideration.

For example, in wet hydrogen sulfide conditions, Hastelloy or Monel alloys conforming to NACE MR 0103 standards are used to slow down the corrosion rate.

In high-temperature hydrogen-contaminated conditions, hydrogen molecules are very small and easily enter and penetrate the crystal lattice of the contacting metal material. In engineering, gold plating can be applied to the diaphragm surface. This effectively slows down the hydrogen permeation rate.

For abrasive media, thickened diaphragms or diamond diaphragms are used. Tantalum is preferred for chlorine-containing corrosive media. Monel alloy is used for alkaline corrosive media. Other technologies include ceramic membrane technology and fluoropolymer lining technology.

Table 1. Effects of ambient temperature on diaphragm specifications

| Diaphragm Specifications | Drift (kPa/10C) |

| DN50 (Stainless Steel Diaphragm) | 0.203 |

| DN80 (Stainless Steel Diaphragm) | 0.011 |

| DN100 (Stainless Steel Diaphragm) | 0.004 |

Table 2. Effects of process temperature on diaphragm specifications

| Diaphragm Specifications | Drift (kPa/10°C) |

| DN50 (Stainless Steel Diaphragm) | 0.124 |

| DN80 (Stainless Steel Diaphragm) | 0.017 |

| DN100 (Stainless Steel Diaphragm) | 0.008 |

Diaphragm Size Selection

Common diaphragm sizes are DN50, DN80, and DN100. The temperature effect on single-sided flange diaphragms without capillary tubes is shown in Tables 1 and 2.

Increasing the diaphragm size appropriately can provide better measurement sensitivity. For low-range differential pressure measurements, it is recommended to use a larger diaphragm size to improve sensitivity. DN50 or DN80 sizes are commonly used in engineering.

Selection of filling fluid

Table 3. Properties of commonly used filling fluids (25℃)

| Filler Fluid | Temperature Limit/°C(Absolute Pressure p<100kPa) | Temperature Limit°C(Absolute Pressure p>100kPa) | Relative Density | Coefficient of Thermal Expansion/(mLc) | Viscosity/(MPa·s) |

| DC200 Silicone Oil | -45~100 | -45~205 | 0.93 | 0.00108 | 9.5 |

| DC704 Silicone Oil | 0~200 | 0~315 | 1.07 | 0.00095 | 44 |

| Halogenated Silicone Oil | 45~175 | -45~175 | 1.85 | 0.000864 | 6.5 |

| SYLTHERMTMXLT | Not Applicable | -75~150 | 0.85 | 0.001199 | 1.6 |

Different filling fluids have different temperature-pressure operating ranges. The selection of the filling fluid should be based on both the process limit temperature and the environmental limit temperature.When selecting a filling fluid, we need to consider not only the applicable temperature, but also the viscosity and coefficient of thermal expansion of the filling fluid. This is especially important when using longer capillary tubes or in environments with large temperature differences.

For example, if the maximum process limit temperature is 280℃, high-temperature silicone oil is required. Silicone oil has a low coefficient of thermal expansion (approximately 9.5 × 10⁻⁴/℃), which is well-suited to this condition and can reduce additional errors caused by temperature fluctuations. Ordinary silicone oil is suitable for operating conditions from -50℃ to 280℃. High-temperature silicone oil (temperature resistance ≥300℃) requires a larger inner diameter capillary tube (e.g., 1.9mm) to balance response time and error.

In cold regions of northern China, transmitters using high-temperature silicone oil as the filling fluid cannot be used directly. Appropriate heating and insulation treatment of the capillary tube is necessary, and the operating temperature range of the transmitter should also be considered.

The longer the capillary tube and the larger its inner diameter, the larger the volume of the filling liquid, and the greater the impact of thermal expansion and contraction. Simultaneously, a longer capillary tube also results in a longer measurement response time. Therefore, the capillary tube length should not be too long, and the inner diameter should not be too large to minimize additional errors caused by temperature changes.

Generally, a capillary inner diameter of 1.1 mm is suitable for ordinary silicone oil. For high-temperature silicone oil (applicable temperature upper limit ≥300℃), a capillary inner diameter of 1.9 mm is suitable. Using a filling liquid with lower viscosity helps to improve the response time.

Capillary Tube Selection

Capillary tubes for dual-flange differential pressure level transmitters are typically available in various lengths and inner diameters. The instrument’s response time and measurement accuracy are significantly affected by the capillary tube length, inner diameter, and filling fluid characteristics.

Longer capillary tubes result in a longer pressure transmission distance, increasing response time. Smaller capillary tube inner diameters lead to a more pronounced throttling effect and greater pressure transmission resistance, also increasing response time.

In theory, capillary tubes with equal sides and the same inner diameter are typically selected, along with the same type of filling fluid. However, when using capillary tubes with unequal lengths on both sides or capillary tubes on one side, the filling fluid will expand and contract due to temperature changes. This will cause measurement errors. Special requirements should be addressed by consulting the manufacturer.

The selection of capillary tube length should be based on the upper/lower flange distance, the instrument’s installation conditions, and the operating environment. It should meet measurement requirements while being as short as possible.

Advantages and Challenges

Advantages:

- Stability and Cost-Effectiveness.

The differential pressure transmitter operates on a mature measurement principle, is less affected by media density, and is suitable for long-term operation.

- Wide Range of Applications.

The differential pressure transmitter can measure high-temperature, viscous media, and media containing solid particles. Suitable for industries such as chemical and food processing.

- High Pressure Withstandability.

The pressure sensing diaphragm inside the transmitter responds only to the pressure difference. Therefore, in high-pressure pipeline applications, atmospheric pressure is irrelevant to the measurement.

- Remote Transmission and Automation.

The differential pressure transmitter supports 4-20mA signal output, facilitating integration with SCADA systems for remote monitoring.

- Accuracy and Calibration.

The intelligent differential pressure transmitter supports automatic zero-point/full-scale calibration, reducing human error.

However, the use of capillary tubes also presents some challenges. Capillary tubes are commonly used in remote installation systems for differential pressure level transmitters. They allow the transmitter to be connected to a diaphragm seal at the process measurement point.

In closed systems, gas pressure is directly proportional to its temperature. In larger pipelines, increases in temperature or pressure have little effect on differential pressure readings. However, within the confined space of a capillary tube, any temperature change is amplified.

The fluid within the capillary tube can increase the system’s response time. This is often a factor that must be considered for remote mounting and temperature compensation.

In dirty or viscous applications, the small diameter of the capillary tube is prone to clogging. Therefore, for certain media, direct mounting or larger diameter pulse lines may be more suitable.

Installation and Calibration of Differential Pressure Level Transmitters

Installation

1. Install the transmitter.

Install the transmitter below the liquid pressure tap and ensure it is securely mounted.

2. Connect the pulse line.

Connect the high-pressure side to the tank bottom and the low-pressure side to the tank top or a separate pulse line. For steam applications, the transmitter should be installed below the orifice plate.

3. Ensure the line is full of liquid.

For level measurement in open tanks, the pulse line should be full of liquid. For closed tanks with dry lines, the low-pressure side can be vented to the atmosphere.

4. Use a remote seal appropriately.

For corrosive or high-temperature fluids, a remote seal should be used to protect the transmitter.

Calibration

1. Before starting, isolate the transmitter from the process.

2. Prepare the calibration setup

We need to connect the digital pressure source to the high-pressure side of the transmitter. Then, connect a digital multimeter in series with the transmitter to measure the output current.

At this point, we close the low-pressure shut-off valve and open the balancing valve. Finally, we close the high-pressure shut-off valve.

3. Perform zero-point fine-tuning

Apply zero pressure to the transmitter. Adjust the zero-point setting until the output current is 4mA. This step should be performed with equal pressure on both sides.

4. Perform range fine-tuning

Apply the rated maximum pressure to the high-pressure input. Adjust the range setting until the output current is 20mA.

5. Repeat and verify

Repeatedly fine-tune the zero point and range. Stop adjusting when both the zero point and range inputs reach the desired output values.

6. After calibration, the transmitter needs to be restored to operation.

More Pressure and Level Measurement Solutions

Differential pressure transmitters are versatile industrial instruments. These rugged devices are essential in process industries, providing accurate measurements for flow, level, and pressure applications. These sensors are widely used in industries such as chemical, petroleum, and food processing.

Sino-inst differential pressure transmitters are rugged industrial solutions. They are widely used worldwide for flow, level, and pressure measurement. When selecting a differential pressure transmitter, you need to consider the differential pressure value, the medium, and the operating temperature. Visit our product page to learn more about differential pressure transmitters.

If you need to purchase a differential pressure transmitter or have any related technical questions, please feel free to contact our engineers!

-1.jpg)