Liquid nitrogen is a commonly used industrial gas with extremely low temperature, strong cooling capacity, and controllability. Liquid nitrogen has important applications in various industries, so it is important to monitor and control the liquid nitrogen level. Our liquid nitrogen tank level meter is a device used to monitor the liquid nitrogen level in ultra-low temperature containers (such as Dewar flasks).

Case Sharing

A customer from the Middle East consulted us about low-temperature liquid level meters. With our help, the customer confirmed the technical parameters.

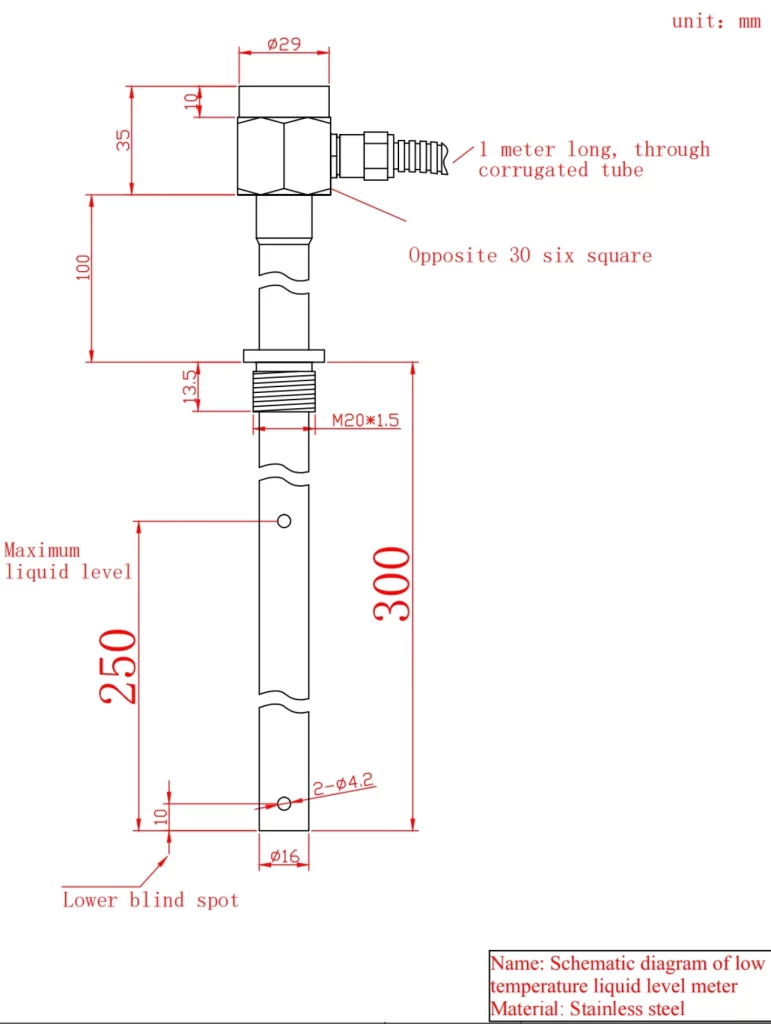

- Low temperature liquid level meter

- Measure liquid nitrogen

- Internal pressure 1.5MPa.

- Output signal: 0-5V

- Total length: 300 mm

- Highest liquid level: 250 mm

- Thread is M20*1.5

- 24vdc

- No display

Working Principle Of Liquid Nitrogen Level Meter

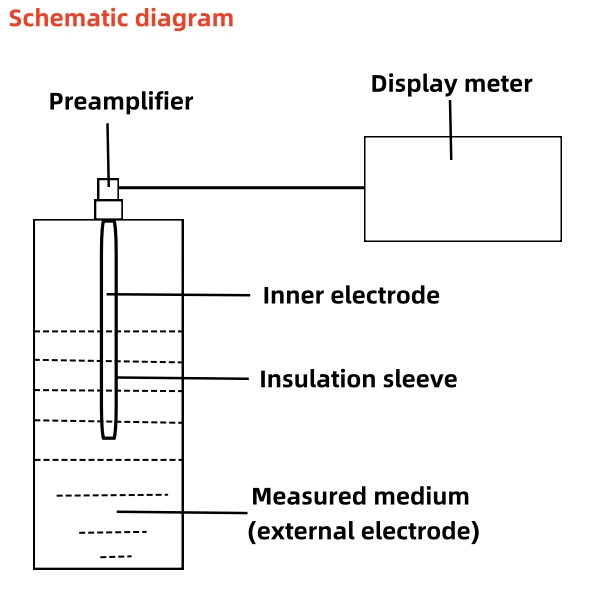

As shown in the figure above, a metal rod is inserted into the liquid nitrogen tank. At this time, the metal rod serves as one pole of the capacitor and the tank wall serves as the other pole of the capacitor. The medium between the two electrodes is the liquid and the gas on the liquid surface. Due to the different dielectric constants of liquids and gases, when the liquid level rises, the total dielectric constant value between the two electrodes increases accordingly, and thus the capacitance increases.

Conversely, when the liquid level drops, the total dielectric constant value decreases and the capacitance also decreases. Therefore, the liquid nitrogen tank level meter can measure the height of the liquid level by measuring the change in capacitance between the two electrodes.

Application Of Liquid Nitrogen Level Meter

Biological laboratory: In the fields of cell preservation, sperm, and embryo freezing, liquid nitrogen tanks can store samples for a long time. The liquid level meter accurately monitors the amount of liquid nitrogen to ensure that the sample is always in a suitable low temperature environment to avoid damage to the sample due to insufficient liquid nitrogen.

For example, in cell culture experiments, the liquid level meter displays the liquid nitrogen level in real time. This makes it convenient for scientific researchers to replenish liquid nitrogen in time to ensure cell activity.

Industry: Liquid nitrogen is needed for cooling in the production processes of the chemical industry and the electronics industry. The slightest carelessness in the cooling step may cause production losses and safety accidents. Therefore, real-time monitoring of the liquid nitrogen level is crucial for chemical reactions and metal cooling.

Aerospace material research and testing: Aerospace materials need to simulate the space environment for various experiments during the research and development and testing stages. Researchers can use liquid nitrogen to create a low-temperature environment close to space. Liquid nitrogen tank level meters can be used to monitor the supply of liquid nitrogen in low-temperature experimental devices.

Technical Advantages

The real-time performance of capacitive level meters is one of the important features of liquid level monitoring. Capacitive level meters can achieve continuous and real-time measurement of the liquid level in the tank, and transmit the measurement data to the operator or manager quickly and accurately. Operators can timely understand the changes in the liquid level in the tank based on these real-time data, predict the liquid level trend in advance, and thus formulate and adjust scientific and reasonable liquid level control strategies.

In order to adapt to various complex industrial environments, capacitive level meters use high-quality stainless steel materials in design and manufacturing. Stainless steel has excellent corrosion resistance, wear resistance and high strength, can resist the erosion of a variety of chemical substances, and can work stably for a long time even under harsh working conditions.

Whether in humid coastal areas, high-temperature and high-pressure chemical workshops, or storage tanks containing corrosive media, stainless steel capacitive level meters can maintain good performance and provide reliable protection for liquid level measurement.

In addition, the capacitive level meter can be customized in length and installation interface according to customer requirements to adapt to storage tanks of different sizes. And there are no moving parts, and basically no daily maintenance is required, which saves customers energy and money.

More solutions for level measurement

- Magnetic Level Measurement: Indicators,Transmitters, Switches Or Sensors

- GWR Type Level Transmitter: An All-inclusive Guide

- Different Solutions for Fluid Level Measurement

- Float Type Level Transmitters for Continuous Level Measurement

- All-inclusive Guide To Bin Level Measurement Systems

- An Out-and-Out Guide To Different Types Of Level Transmitters

- Bitumen And Asphalt Level Meters: Let’s Learn More About Them

- Dry Materials-Bulk Solids-Powder Level Sensors Guide

- Role of Hydrostatic Level Transmitters In Well Water Level Monitoring Process

- Typical Ultrasonic Level Sensor Applications and Advantages

- Difference Between Radar and Ultrasonic Level Transmitters

- Industrial Ultrasonic Level Transmitters | Non-contact Level Measurement

- Featured 5 Guided Wave Radar Level Transmitter Types

- Guided Wave Radar Level Transmitter Installation Guide and Troubleshooting

- Hydrostatic Level Measurement-Liquid Level Measurement with Pressure Sensors

- Difference Between Radar and Guided Wave Radar Level Transmitter

Summary

Sino-Inst’s capacitive level meter has a simple structure, no moving parts, and fast dynamic response. It can be widely used in liquid level measurement in harsh environments such as high temperature, low temperature, and strong corrosion. Customers in Taiwan, China, the Middle East, Europe and the United States have purchased our products.

Our capacitive level meter supports customized pressure, temperature, probe length and installation method, aiming to customize the most suitable product for each customer. If you have any needs, please feel free to contact us.

-1.jpg)