Flow meters focus on measuring gasses and liquids in pipes. Improving the precision, accuracy, and resolution of fluid measurement are the greatest benefits of the best flow meters.

The material used to construct the frame of a flow meters play a big role in making a flow meter the best flow meter for a particular application. Two favorite materials used in the construction of flow meters are stainless steel and PTFE (Polytetrafluoroethylene). Both offer unparalleled properties that make them appropriate for different applications.

The Importance of Material Selection for Flow Meters

The material from which a flow meter is constructed has a significant impact on its durability, performance, and compatibility with the measured fluid.

Both stainless steel and PTFE offer excellent characteristics that make them valuable for different flow metering applications.

Understanding the properties of each material is essential for selecting the right flow meter for a particular project. Main considerations: temperature, pressure, medium corrosiveness, etc.

Stainless Steel Flow Meters: Durability, and Preciseness

The stainless steel flow meter is an advanced flow measurement device designed to accurately measure and monitor the flow of various liquids and gases. With its cutting-edge technology and reliable performance, it has become the solution of choice in oil and gas, chemical processing, renewable energy systems, water treatment and many other industries.

Benefits of Stainless Steel Flow Meters

- Corrosion Resistance

- High Strength-High pressure resistance

- Temperature Resistance

- Longevity

- Accuracy and Reliability

Flow Meters with Stainless Steel Frame

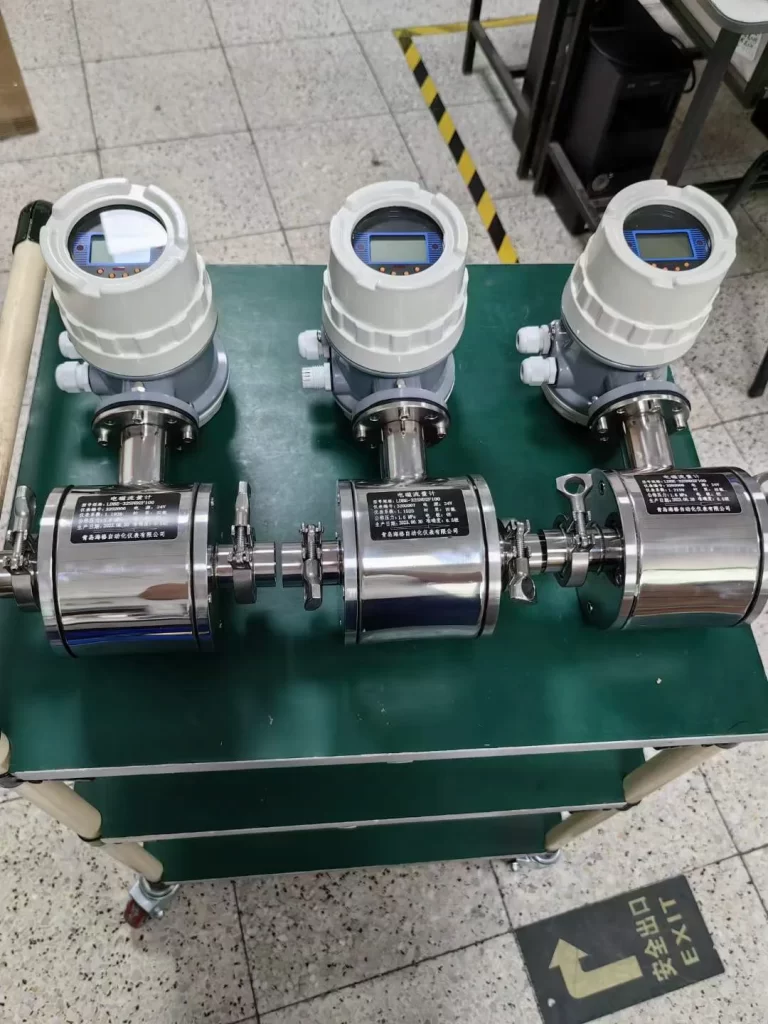

Electromagnetic flowmeter:

An electromagnetic flowmeter (or magnetic flowmeter) is a velocity or volume flowmeter that works according to Faraday’s law of electromagnetic induction. They are very accurate and can handle a variety of fluids from mud to pure water.

Electromagnetic flowmeters can be configured with a full stainless steel body. They are used in the sanitary industry, or for the measurement of high-pressure fluids. High pressure can reach 42MPa.

Positive displacement flowmeter:

Positive displacement flowmeters are unique because they are the only meters that directly measure the actual volume. All other types infer flow by taking other types of measurements and equating them to flow.

PD meters include dual rotor types (gear, oval gear, helical gear), reciprocating pistons, and oscillating or rotating pistons.

Gear flowmeters in particular are made of all stainless steel and can withstand high temperatures of 40MPa, or extreme temperatures of ±200℃.

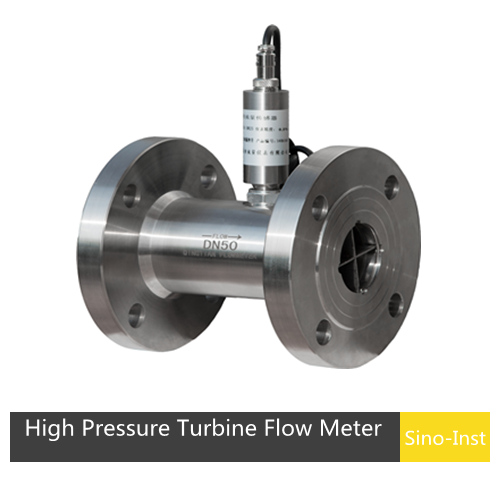

Turbine flowmeter:

A turbine flowmeter is a velocity meter. It can be used to measure low-viscosity and low-corrosive liquid media. Common configurations include body material 304 stainless steel and impeller 2Cr13.

Mass flow meter:

The mass flow meter can directly measure mass flow, which is not affected by temperature, pressure, flow rate, etc. It can display parameters such as mass flow, volume flow, cumulative flow, density, temperature, etc. The measuring tube material is 316L, and the shell material is 304. It can measure uniform fluids of general viscosity, high-viscosity fluids, and non-Newtonian unidirectional fluids.

Usage of Stainless Steel Flow Meters

- Oil and Gas Industry

- Water Treatment

- Pharmaceuticals

- Food and Beverage

PTFE Flow Meters: Chemical Resistance

Incorporating the principles of traditional flow technology, PTFE flow meters offer solutions to low to medium-flow range measurements of highly corrosive or ultra-pure liquids. These meters are a unique combination of a rugged mechanically rigid frame and chemically inert wetted parts.

PTFE Flow meters are also resistant to external, ambient corrosive environments. For the protection of personnel, each flow meter is supplied with a safety shield.

Benefits of PTFE Flow Meters

- Chemical Resistance

- Non-Stick Surface

- Thermal Stability

- Low Friction

- Lightweight

Flow Meters with PTFE Frame

Gear flowmeter:

Our gear flowmeter can be equipped with a new PTFE material. It is used for measuring small flow rates.

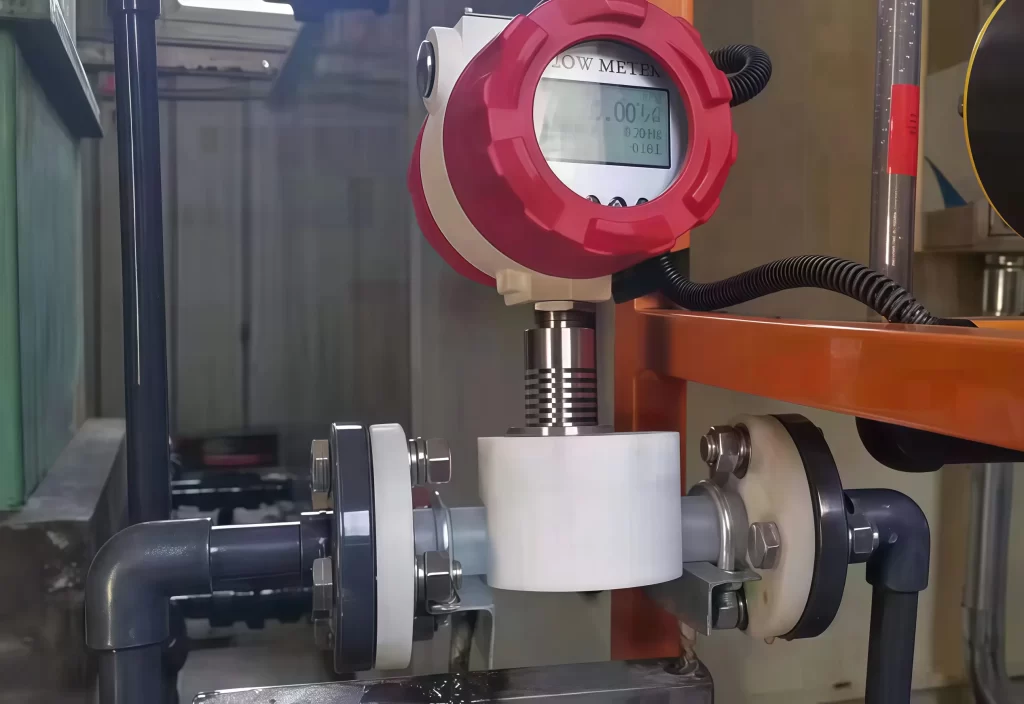

Turbine flowmeter:

Turbine flowmeter can also be equipped with PE material. It is used to measure the flow of corrosive liquids.

Electromagnetic flowmeter and rotor flowmeter:

An electromagnetic flowmeter can be equipped with an anti-corrosion lining. This can also measure the flow of corrosive liquids. For example, PTFE lining, PFA lining, etc.

The rotor flowmeter can be equipped with PTFE lining. Used to measure corrosive gases and liquids.

Usage of PTFE Flow Meters

- Chemical Processing

- Pharmaceuticals

- Food and Beverage

- Semiconductor Manufacturing: The semiconductor industry often uses PTFE flow meters to measure ultra-pure chemicals and gases without contamination.

Popular Stainless Steel and PTFE Flow Meters from Sino-Inst

Stainless Steel vs PTFE Flow Meters: Which is Right for You?

Stainless Steel Flow Meters are ideal for:

- High-pressure, high-temperature, and abrasive applications.

- Environments where durability and reliability are crucial.

- Applications where high precision is needed for non-corrosive fluids (e.g., water, gases).

PTFE Flow Meters are ideal for:

- Highly corrosive, aggressive, or reactive fluids, including acids, solvents, and bases.

- Applications where a non-stick surface or low friction is important.

- Low-flow or highly viscous applications that require precise measurements.

More Flow Measurement Solutions

- Sewer Flow Meters and Their Importance in Sewer Monitoring

- The Next Level Of Flow Measurement: Here Come Non-Intrusive Flow Meters

- Right Flow Meter For Breweries: Exploring Food Grade Flow Meters

- An Extensive Guide On Magnetic Inductive Flow Meters

- Flow Measurement For Powders And Granular Materials: Solid Flow Meter

- Rotameter vs Flow Meter

- High Accuracy Flow Meters: A Key To Precision In Flow Measurement

- Guide for High Pressure Flow Meters – Industrial Liquid & Gas Measurement

- Guide To Low Temperature Flow Meters: Accuracy In Cold Fluid Measurement

Both stainless steel and PTFE flow meters offer unparalleled benefits that make them valuable tools in industrial settings. Stainless steel flow meters excel in environments requiring high durability, strength, and temperature resistance, making them ideal for industries like oil and gas, water treatment, and pharmaceuticals.

On the other hand, PTFE flow meters are unmatchable in their chemical resistance, making them indispensable in industries dealing with aggressive or reactive chemicals, such as chemical processing and food production.

As discussed above, our company provides a remarkable choice of both stainless steel and PTFF flow meters according to customer demand. If you have any questions about selection, please feel free to contact us!

-1.jpg)