Low flow meters are flow measurement devices that are specialized for measuring small liquid volumes and low flow rates. These are essential for high-precision process monitoring and controlling liquid flow. For example, in industries such as pharmaceuticals and chemicals, high-precision consistency of ingredients needs to be ensured.

In this guide, we will take a deep dive into the various types of low flow meters, their applications, and factors to consider when choosing a flow meter that suits your needs.

Featured Low Flow and Low Volume Flow Meters

Sino-Inst also offers a wide range of low flow measurement solutions on the global market. There are a variety of models to choose from, including low flow mass flow meters. Choosing the right low flow meter depends on the actual conditions of your process.

Types of Low Flow Meters

Coriolis Mass Flow Meters

It measures mass flow directly and independently of the liquid’s attributes. The Coriolis provides mass flow and density measurements that are both repeatable and highly accurate, even when the composition of the liquid is unknown or changing.

Using the principle of accelerating a moving fluid and detecting the reaction on the vibrating tube with sensors, Coriolis meters are very sensitive and flows lower than 0.2 ml/min are possible.

All-inclusive material compatibility, which can be used for either liquid or gas flow measurement. They are independent of liquid or process variables.

The primary limitation is that the flow must be single-phase and of low viscosity. They are also expensive devices so would not be suitable for low-cost low flow applications.

Positive Displacement (PD) Flow Meters

Positive displacement flow meters, such as oval gear flow meters are one of the few alternatives that measure very low flow rates without requiring external power.

They work by capturing small amounts of fluid within cavities and then counting the number of times these cavities fill and empty.

PD meters are known for their high accuracy and are appropriate for viscous liquids in low-volume applications, such as oil metering and fuel measurement.

Especially our newly developed GF series spur gear flow meters. Especially suitable for low-volume solution flow measurement.

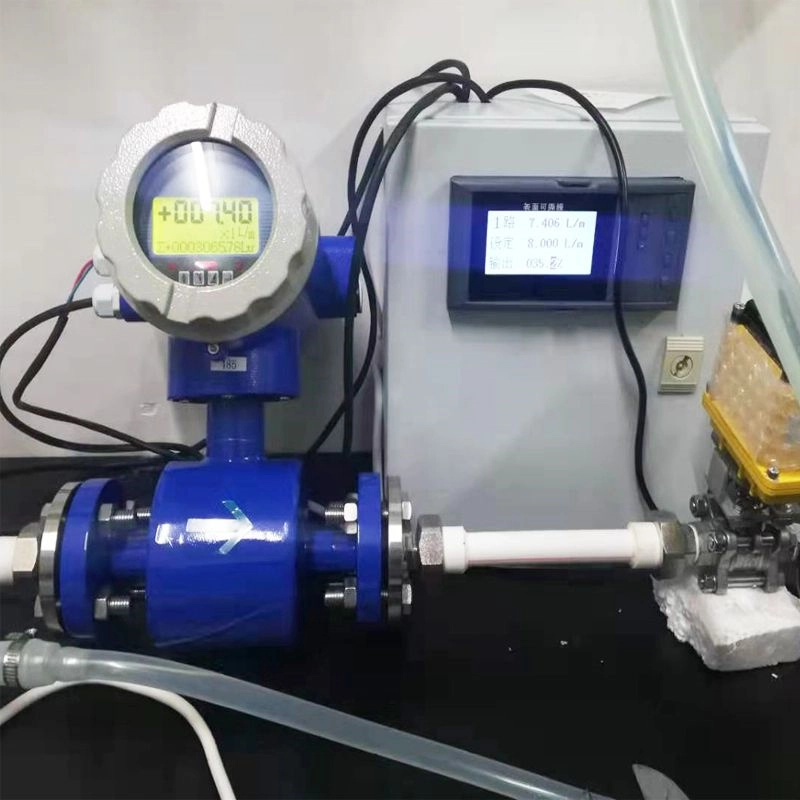

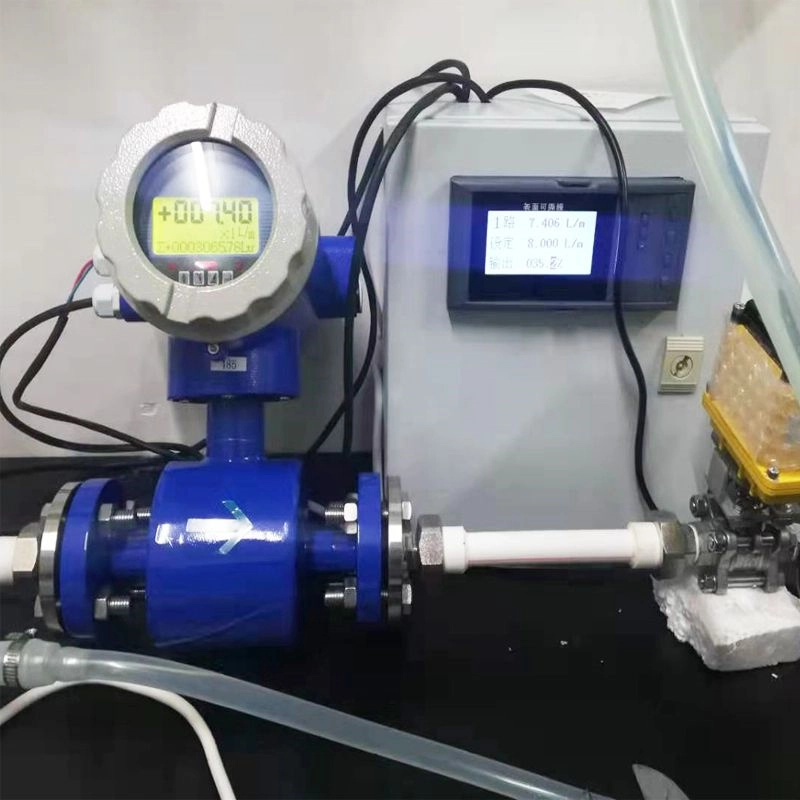

Electromagnetic Flow Meters

Electromagnetic flow meters use the principle of Faraday’s law of electromagnetic induction to measure the flow rate of conductive liquids.

They are highly dead on target and ideal for low flow rates but only work with conductive liquids, such as water or wastewater. Due to their limited application to non-conductive fluids, they are typically found in water and environmental monitoring applications.

Turbine Flow Meters

Turbine flow meters operate by detecting the rotational speed of a turbine wheel within the flow stream, which is proportional to the flow rate. Pelton wheel turbines that use low friction are capable of flows down to 1-2ml/min. They are competent in fast response times and operate across wide flow and operating temperature ranges.

Advantages include they are cheap, and can be calibrated in situ. They have good accuracy and repeatability with rapid response times.

But turbine flow meters are susceptible to changes in fluid properties. They require sufficient pressure to move liquid through the pipeline at a rate that causes the turbine blades to spin.

Ultrasonic Flow Meters

Ultrasonic flow meters can quickly measure small flow pipes, minimum DN6. Flow velocity range 0.1m/s~5.0m/s. Especially our X3 clamp ultrasonic flow meter.

The flow meter is clamped outside the pipe, and no additional changes to the pipeline are required. No professional knowledge is required, and installation and measurement can be completed according to the operating instructions. There are no moving parts, no pressure loss, and no need to stop production for installation and use.

Applications of Low Flow Meters

- Pharmaceuticals

- Food and Beverage

- Water Treatment

- Oil and Gas

- HVAC and Environmental Monitoring

Significant Factors to Consider When Choosing a Low Flow Meter

Flow Rate Limit

Each type of low flow meter has a minimum and maximum flow range it can accurately measure. It’s crucial to select a meter with a range that matches the specific needs of your application.

For example, a low flow mass flow meter may be more suitable if high accuracy at extremely low flow rates is required.

Fluid Type and Attributes

Different flow meters are compatible with various fluids. For example, electromagnetic meters require a conductive fluid, while ultrasonic flow meters are best suited for clean fluids.

Consider the fluid’s viscosity, temperature, and conductivity, as these factors can impact meter performance.

Measurement Accuracy

Measurement preciseness is especially critical in low flow applications. Meters like Coriolis and thermal mass flow meters offer high accuracy for both liquids and gases, whereas turbine meters may provide sufficient accuracy only under specific conditions.

Installation and Maintenance Requirements

Some flow meters, like ultrasonic and electromagnetic meters, require minimal maintenance and are easy to install

. Whereas Gear Flow meters and Mass flow meter do not need to be Installed in straight pipe sections. In critical applications, minimal downtime is essential, so maintenance requirements should align with operational needs.

Environmental Conditions

Consider the environmental conditions, including temperature, pressure, and humidity. For example, Coriolis meters are generally suitable for a wide range of temperatures and pressures, while some ultrasonic meters may have limitations under extreme conditions.

Power Requirements

Power availability is another factor, especially in remote or portable applications. Positive displacement flow meters do not require an external power source, making them ideal for battery-operated or low-power setups.

Challenges in Low Flow Measurement

- Sensitivity to Flow Disturbances

- Viscosity Effects

- Scaling and Clogging

More Flow Measurement Solutions

- Turbine Water Flow Meter: A Versatile And Reliable Choice For Water Flow Measurement

- Pulse Output Flow Meters for Better Water Flow Measurement

- Ultrasonic Clamp On Flow Meter – For Easier Water Flow Measurement

- Industrial Refrigerant Flow Meters

- Getting to Know The Propane Flow Meters: Better Monitoring of Propane Utilization

- 4-20mA Flow Meters | Flow Meter Signal Output Guide

- Analog Flow Meters: An Encompassing Guide

- Industrial Hydraulic Flow Meters | Mechanical & Digital

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Liquid and Gas NH3 Ammonia Flow Meters

- Magnetic Flow Meter Lining Material and Electrode Selection Guide

There is no set definition for ‘low flow’ in terms of measurement limits for fluidics handling. However, low-flow applications encounter amplified flow stability and performance issues not seen in larger flows.

The minimal liquid volume being measured in low flows renders them highly sensitive, such that even the slightest disruptions in process or ambient conditions can exert a substantial impact on flow stability.

Selecting the right flow meter requires careful consideration of factors such as flow rate range, fluid type, accuracy, and environmental conditions. By understanding the different types and their applications, you can ensure optimal performance, accurate readings, and efficiency in your low flow or low volume applications.

-1.jpg)