Compared with traditional contact torque sensors, Contactless Torque Sensor avoids physical contact. This feature significantly reduces wear and energy loss. Improves the reliability of the measurement system.

Contactless Torque Sensor does not mean that the sensor can obtain measurement results without contacting the measured object. Instead, it means that the power supply and signal inside the sensor are transmitted through two sets of coils, and there will be no friction loss when the sensor rotates. The advantage of this sensor is that it can rotate at high speed and has a long service life, and it can also measure the rotation speed or rotation angle at the same time.

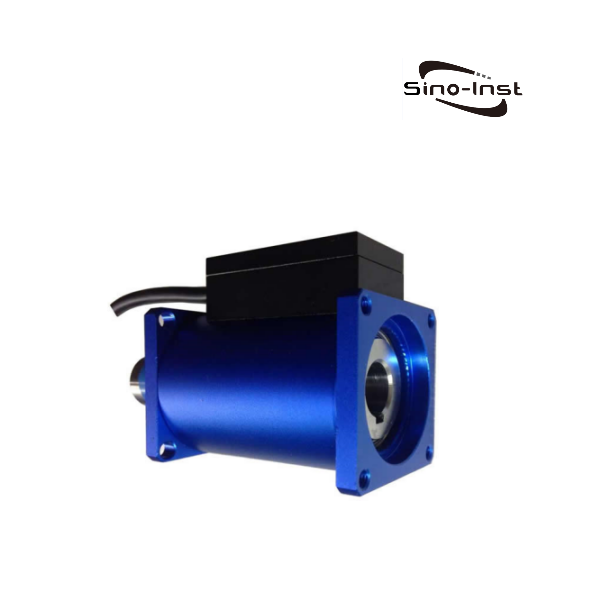

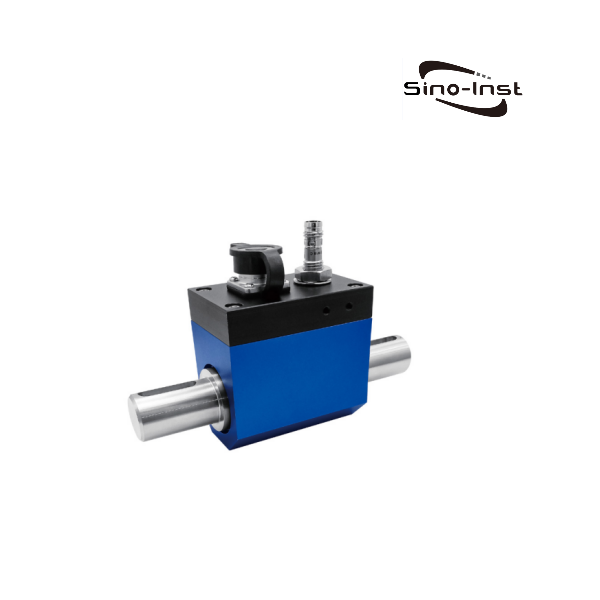

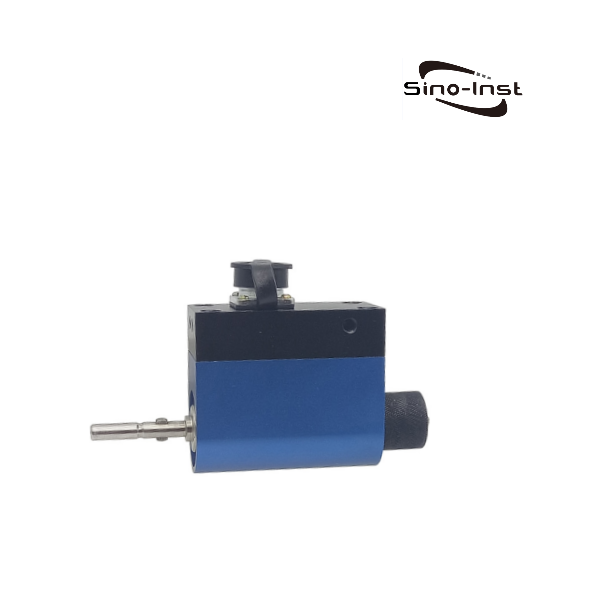

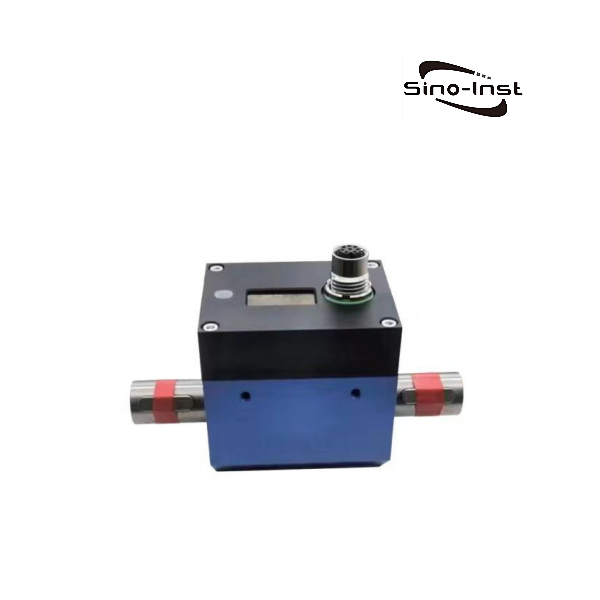

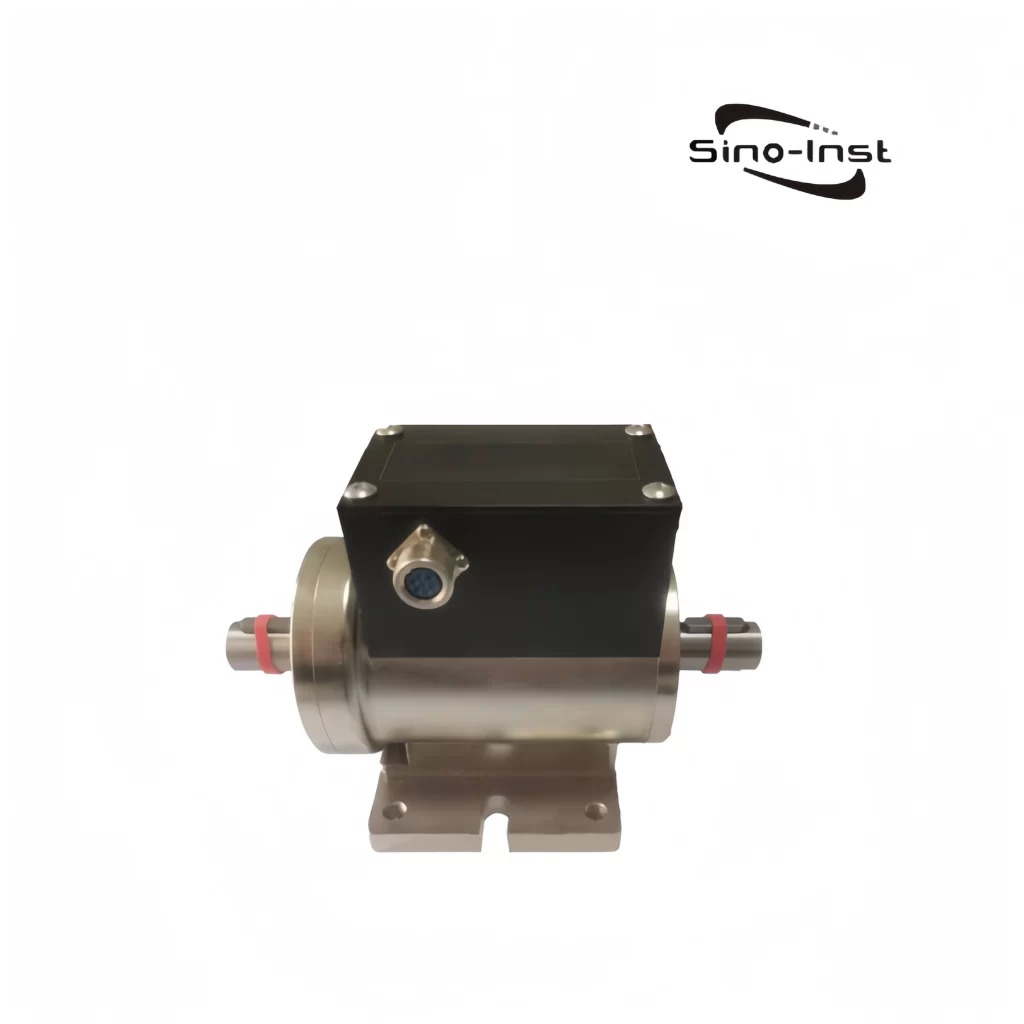

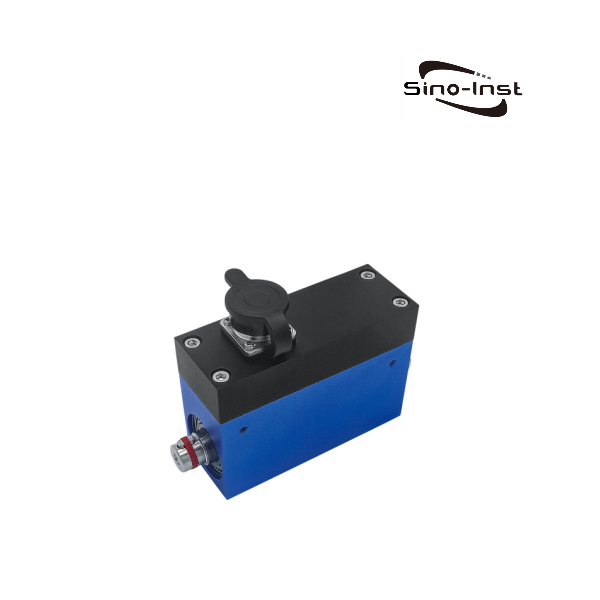

Featured Contactless Torque Sensors

Sino-Inst provides Contactless Torque Sensors for various industrial production and laboratories. The measurement range covers 0-0.1Nm, 100KNm. It can be customized to measure torque, speed, power, angle, etc.

Contactless Torque Sensor Technology

For traditional contact sensors, there are some contact problems. Long-term friction can easily cause machine wear, resulting in the measurement accuracy not meeting the specified requirements. This results in a reduction in life. It requires staff to frequently repair or even replace it, which is not very practical. It also increases various expenditures and has poor economic efficiency.

Contactless Torque Sensor is also a dynamic torque sensor, also known as a torque sensor, torque speed sensor, rotary torque sensor, etc.

Working Principle

The working principle of non-contact torque sensor is mainly based on magnetic or optical technology. Compared with traditional contact sensors, non-contact sensors avoid physical contact, which significantly reduces wear and energy loss and improves the reliability of the measurement system.

1. Magnetic induction principle: usually a ring magnet or electromagnet is used. When torque is applied, the internal magnetic field changes. By accurately measuring these changes, the system can calculate the applied torque value.

Its input shaft and output shaft are connected by a torsion bar. There are splines on the input shaft and keyways on the output shaft. When the torsion bar is twisted by the torque, the relative position of the spline and the keyway is changed. The change in their relative displacement is the torsion of the torsion bar. This process causes the magnetic induction intensity on the spline to change, which is converted into a voltage signal through the coil.

2. Optical principle: Another form of non-contact sensor is based on optical technology. Use laser or other light sources to emit light beams and capture changes in reflected light. When torque acts on the measured shaft, the characteristics of the reflected light will change. By analyzing these changes, the applied torque can be measured in real time.

Composition and design

Non-contact torque sensors are usually composed of several core components:

- Detection unit: responsible for capturing and converting measurement signals.

- Signal processor: Filters, amplifies and analyzes the captured signals.

- Output interface: Outputs the processed results in the form of standard signals. For example, analog signals or digital signals. It is convenient for subsequent data recording and processing.

Benefits

Non-contact torque sensors have multiple advantages over traditional sensors:

More Torque Measurement Solutions

Contactless Torque Sensor has become an important tool in the field of torque measurement with its advanced working principle and design. The performance and application range of the sensor are still expanding, and it will play a key role in a wider range of industrial fields in the future.

Sino-Inst supplies high-precision and high-reliability torque measurement solutions. Non-contact torque sensor is undoubtedly a worthy solution. If you need to purchase Contactless Torque Sensor, or have related technical questions, please feel free to contact us.

-1.jpg)