Ultrasonic Heat Meters have a heat accumulation function and are used to measure the thermal energy consumed in heating systems or chilled water. The ultrasonic flow meter is equipped with a pair of platinum resistors temperature sensor . And the international standard thermal exact value heat calculation formula (exact difference method) can be used to achieve the measurement of cooling capacity/heat.

Our Sino-Inst YFM-100 series products are divided into portable, integrated, split, modular and battery-powered types. It is suitable for cooling/heat measurement of air conditioners and heat measurement of units, buildings, heat exchange stations and heating company pipe networks.

Our Sino-Inst YFM-100 series ultrasonic heat meters are commonly used in 4 styles: integrated type, split type, modular type and battery-powered. The following is a detailed parameters introduction:

Integrated Ultrasonic Heat/Cold Meter

The YFM-100RY integrated ultrasonic cold/heat meter avoids errors caused by human and piping factors during the installation process of clamp-on and insertion sensors. It has the advantages of high precision, wide range ratio, no pressure loss, and simple installation.

| Measurement accuracy: | Meet EN1434 standard |

| Measurement cycle: | 500ms (2 times per second, 128 sets of data collected per cycle) |

| Working power supply: | Isolated DC8~36V or AC85λ264V optional |

| Maximum flow velocity: | 64m/s (flow velocity resolution 0.001m/s) |

| Calorie unit: | Gigajoles, kilocalories, BTU optional |

| Display: | 2×10 Chinese character backlight display (Chinese and English bilingual optional) |

| Operation: | Magnetic 4-button window operation |

| Platinum resistor: | PT100 three-wire platinum resistor |

| Signal input: | 3 channels of 4-20mA analog input, accuracy 0.1%, can input pressure, liquid level, temperature and other signals |

| Signal output: | 1 isolated RS485 output 1 channel isolated OCT (pulse width programmable between 6λ1000ms, default 200ms) 1 relay output (pulse width 200ms) 1 channel 4-20mA output (active/passive output optional) 1 bidirectional serial peripheral universal interface, which can connect multiple external devices in series. (Such as massive data storage modules, printers, etc.) |

| Communication protocol: | M-BUS protocol, MODBUS protocol, FUJ1 extended protocol, and compatible with communication protocols of similar products from other domestic manufacturers. |

| Other functions : | Automatically remember the previous 512 days, the previous 128 months, and the positive/negative/net cumulative traffic in the previous 10 years Automatically memorizes the previous 30 power-on and power-off times and flow rates, and can realize automatic or manual replenishment. Software upgrades can be implemented via code files sent via E-mail. |

| Power outage protection: | data will not be lost after 100,000 hours of power outage |

| Protection level: | IP68 |

| Electrical interface: | M16×1.5 |

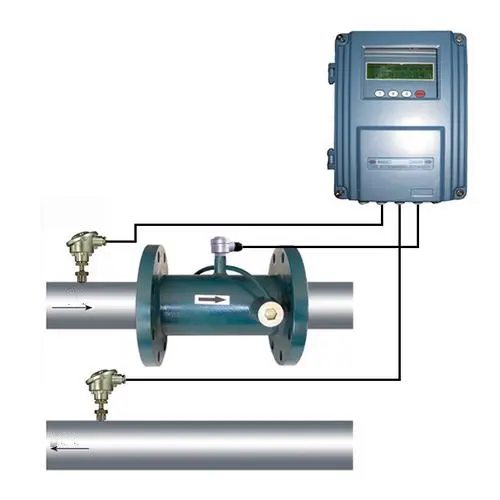

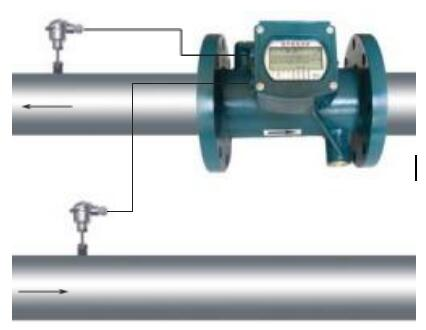

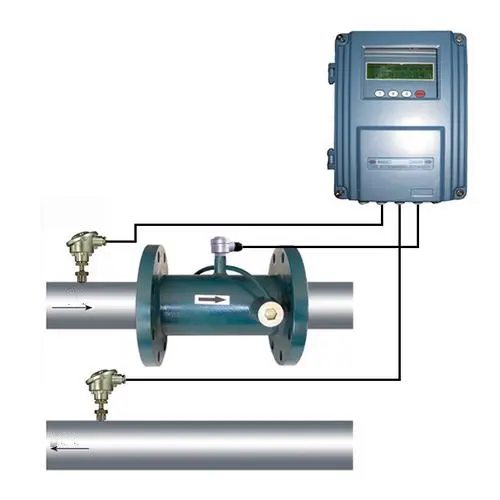

Split type Ultrasonic Heat/Cold Meter

YFM-100F series fixed split type ultrasonic cold/heat meter is widely used in online measurement of heating pipe network.

The host is divided into wall-mounted standard type, wall-mounted explosion-proof type, panel-mounted type and local display type. The sensors are divided into external-mounted type, plug-in type, pipe segment type, etc.

| Measurement accuracy: | Meet EN1434 standard |

| Measurement cycle: | 500ms (2 times per second, 128 sets of data collected per cycle) |

| Working power supply: | 85λ264VAC/isolated 24VDC (F4 type 8λ36VDC) |

| Maximum flow velocity: | 64m/s (flow velocity resolution 0.001m/s) |

| Calorie unit: | Gigajoles, kilocalories, BTU optional |

| Display: | Backlit LCD, can display instantaneous heat and positive, negative, net accumulated heat, etc. |

| Operation: | 4×4 touch keyboard or magnetic 4-button (F4 host) operation |

| Platinum resistance: | PT100 three-wire platinum resistance |

| Signal input: | 3 channels of 4-20mA analog input, accuracy 0.1%, can input pressure, liquid level and other signals |

| Signal output: | 1 isolated RS485 output 1 channel 4-20mA or 0-20mA output 1 channel isolated OCT (pulse width programmable between 6λ1000ms, default 200ms) 1 relay output (pulse width 200ms) |

| Communication protocol: | MODBUS protocol, M-BUS protocol, FUJ1 extended protocol, and compatible with communication protocols of similar products from other domestic manufacturers |

| other functions: | Automatically memorize the previous 512 days, the previous 128 months, and the previous 10 years of positive/negative/net cumulative traffic Automatically memorizes the previous 30 power-on and power-off times and flow rates, and can realize automatic or manual replenishment. Programmable batch (quantitative) controller, fault self-diagnosis function Software upgrades can be implemented via code files sent via E-mail. |

| Protection level: | sensor IP68, F4 host IP68, other hosts IP65 |

| Explosion-proof level: | EXdIBT4 (YFM-100F2 type) |

Optional flow sensor

Modular type ultrasonic cold/heat meter

The YFM-100RM ultrasonic cold/heat module is a product specially designed for heating network monitoring projects. It has the characteristics of small size, low price, simple operation, and complete output interface functions.

| Measurement accuracy: | Meet EN1434 standard |

| Working power supply: | Isolated 8λ36VDC |

| Display: | Backlit LCD display can display instantaneous heat, flow rate, positive and negative net accumulated heat, etc. |

| Operation: | 4-key touch keyboard to set parameters |

| Platinum resistance: | PT100 three-wire platinum resistance |

| Calorie unit: | Gigajoles, kilocalories, BTU optional |

| Signal input: | 3 channels of 4-205A analog input, accuracy 0.12l, can input pressure, liquid level, temperature and other signals |

| Signal output: | 1 channel isolated RS48N output 1 channel isolated OCT (pulse width programmable between 6λ10005s, default 2005s) 1 relay output (pulse width 2005s) 1 channel 4-205A output (active/passive output optional) |

| Communication protocol: | M-BUS protocol, MODBUS protocol, Haifeng FUJl extended protocol, and compatible with communication protocols of similar products from other domestic manufacturers |

| Other functions : | Automatically memorize the previous N12 days, the previous 128 months, and the positive/negative/net cumulative traffic in the previous 10 years Automatically memorizes the previous 30 power-on and power-off times and flow rates, and can realize automatic or manual replenishment. Software upgrades can be implemented via code files sent via E-mail. |

| Protection level: | IP67 |

| Installation method: | Guide rail type (host) |

Optional flow sensor

Battery Powered Ultrasonic Cold/Heat Meter

YFM-100W series battery-powered ultrasonic cold/heat meter is suitable for cold and heat measurement in non-power supply sites. The main board uses a pre-receiving amplifier with a dynamic range of 50 decibels, and can be equipped with external clip-on, plug-in, and pipe-type sensors.

| Measurement accuracy: | Meets EN1434 standard |

| Repeatability: | Better than 0.5% |

| Working power supply: | 3.6V/19AH lithium battery power supply (normal operation when voltage ≥2.6V) |

| Measurement period: | 500msλ49 seconds (factory default 10 seconds) |

| Sampling times: | 32 groups of sampling times per measurement cycle λ128 groups optional (factory default 64 groups) |

| Display: | Local 96-segment LCD display can display 44 different window contents |

| Operation: | Use special secondary instrument or PC parameter setting software (can be downloaded from the company website), set parameters through RS485, and browse the contents of 44 windows |

| Platinum resistance: | PT1000 platinum resistance |

| Calorie unit: | Gigajoules, kilocalories optional |

| Optional output: | 1 USART(TTL) output 1 non-isolated RS485 output Dual-channel isolated OCT output (pulse width is programmable between 6λ and 1000ms, default is 200ms) 1-channel bidirectional serial peripheral universal interface, which can directly connect multiple external devices in series: 4-20 mA analog output board, frequency signal output board, thermal printer, etc. |

| Communication protocol: | Standard M-BUS protocol, MODBUS protocol, FUJ1 extended protocol, and compatible with similar product communication protocols from other domestic manufacturers |

| Other functions : | Automatically remember the previous 512 days, the previous 128 months, and the positive/negative/net cumulative traffic in the previous 10 years; Automatically memorizes the previous 30 power-on and power-off times and flow rates, and can realize automatic or manual replenishment. Software upgrades can be implemented via code files sent via E-mail. |

| Protection level: | IP68 |

| Sensor: | Pipe type, external clamp-on type, insert type |

Optional flow sensor

About Ultrasonic Heat Meter Sensors

In order to meet the actual working conditions on site and customer needs, YFM-100 series Ultrasonic Heat Meters provide clamp-on type, insert type, and pipe segment type for users to choose from.

The clamp-on type is divided into: standard small S1, standard medium M1, standard large L1, high temperature small S1H, high temperature medium M1H, high temperature large L1H;

Insert type is divided into: standard insert type, water meter insert type, cement insert type, large cement insert type, super large water meter insert type;

The pipe section type is divided into: standard pipe section type (DN50mm~1000mm), m-shaped pipe section type (DN15~40), and sanitary type (DN15~100).

clamp-on type sensors

During installation, the sensor is directly tied to the outer wall of the pipe to be measured. There is no need to break the pipe or stop production. It has the characteristics of simple installation and no pressure loss.

Sensor parameters (applicable to fixed split type, economical type, modular type, battery-powered ultrasonic flow meter/heat meter)

| Technical Parameters | Standard S1 type | Standard M1 type | Standard L1 type | High temperature S1H type | High temperature M1H type |

| Applicable pipe diameter | DN15~DN100 | DN50~DN700 | DN300~DN6000 | DN15~DN100 | DN50~DN700 |

| Material | ABS | Special high temperature materials | |||

| working frequency | 1MHz | ||||

| Installation method | V(N,W) method | V, Z method | Z method | V(N,W) method | V, Z method |

| Calibration | Whole machine pairing and calibration | ||||

| magnetic | Yes | No | |||

| proper temperature | 0℃ ~70℃ | 0℃ ~160℃ | |||

| Protection level | IP68 (Can be submerged in water, water depth ≤3 meters) | ||||

| Dimensions | 45×30×30 | 60×45×45 | 80×70×55 | 90×85×24 | 90×82×29 |

| Mass (gram pairs) | 75 | 250 | 650 | 94 | 150 |

| Media type | Water, seawater, sewage, alcohol, various oils and other single, uniform and stable liquids that can conduct ultrasonic waves | ||||

| Medium turbidity | ≤20000ppm and small bubble content | ||||

| Applicable pipes | Carbon steel, stainless steel, cast iron, copper, PVC, aluminum, fiberglass and other uniform and dense pipes. Linings allowed. | ||||

| Pipe lining | Epoxy asphalt, rubber, mortar, polypropylene, polystyrene, bakelite, polytetrafluoroethylene, etc. | ||||

| Signal cable | SEYV75-2 special shielded cable, a single cable can be lengthened to 500 meters. When wiring, the cable should be covered with a metal sleeve to increase anti-interference. And be careful not to run the cable in parallel with high-voltage cables. Try to avoid interference sources such as frequency converters. | ||||

Insertion sensors

During installation, use a special drilling tool to drill holes in the pipe to be measured, and directly contact the sensor with the measured medium for measurement. It can be installed under pressure without stopping production.

This sensor solves the problem that the clamp-on sensor is difficult to receive signals when measuring thickly scaled pipes and the signal is attenuated for a long time.

It has the characteristics of non-stop installation, maintenance-free, independent of pipe diameter, and no pressure loss.

- When the pipe material is carbon steel or stainless steel, it can be directly welded and installed.

- For pipes that cannot be directly welded, such as cast iron, fiberglass, PVC, cement pipes, etc., they must be installed with special pipe hoops made by us.

- In order to prevent water leakage, users should provide the accurate outer diameter or circumference of the pipe to be measured when ordering.

| Technical Parameters | Standard insert type B | Water meter insert type B | Extended insertion type B (for cement pipes) |

| Applicable pipe diameter | DN80mm and above | ||

| Material | Ball valve and probe: stainless steel 316L; Ball valve base: ordinary carbon steel (stainless steel optional) | ||

| Working frequency | 1MHz | ||

| Applicable pipes | Carbon steel, stainless steel, cast iron, copper, PVC, aluminum, fiberglass, cement pipes and other pipes. Linings allowed. Remark : 1. Carbon steel and stainless steel can be directly welded (stainless steel pipes must use stainless steel bases, users please pay attention when ordering). 2. Other pipes need to be installed with pipe hoops (pipe hoop material: carbon steel, please provide the accurate outer diameter or circumference of the pipe when ordering). | ||

| Installation method | Z method | ||

| Temperature | -40℃ ~160℃ | ||

| Opening size | 19mm/water meter insert 23mm (When installing, use the special hole opener provided by the manufacturer to achieve installation under pressure without stopping production) | ||

| Pressure Level | 1.6MPa (pressure during installation <0.8MPa) | ||

| Protection level | IP68 (can be submerged in water, water depth ≤3 meters) | ||

| Installation space | Well wall to pipe wall ≥550mm | Well wall to pipe wall ≥360mm | Well wall to pipe wall ≥700mm |

| Length | 186mm | 228mm | 330mm |

| Media type | Water, seawater, sewage, alcohol, various oils and other single, uniform and stable liquids that can conduct ultrasonic waves. | ||

| Medium turbidity | ≤20000ppm and small bubble content | ||

| Signal cable | SEYV75-2 special shielded cable, a single cable can be lengthened to 500 meters (the length of the water meter plug-in cable cannot exceed 5 meters). When wiring, the cable should be covered with a metal sleeve to increase anti-interference. And be careful not to run the cables in parallel with high-voltage cables. Try to avoid interference sources such as frequency converters. | ||

Pipe section sensor

Pipe section sensor is a measurement method that uses a flange to directly connect the pipe section sensor to the pipeline under test.

This sensor solves the problem of reduced measurement accuracy of clamp-on and insertion sensors due to errors caused by human effort or inaccurate parameters of the pipe being measured during the installation process.

It has the characteristics of high measurement accuracy, good stability and maintenance-free.

| Technical Parameters | Sanitary pipe sensor | M type pipe section sensor | Standard pipe sensor |

| Applicable pipe diameter | DN15~DN100 | DN15~DN40 | DN50~DN1000 |

| Material | Stainless steel | Carbon steel (stainless steel optional) | |

| Working frequency | 1MHz | ||

| Connection method | Movable connection | Flange/thread optional | Flange connection |

| Temperature | -40℃ ~160℃ | ||

| Calibration | Online calibration of the whole machine | ||

| Protection level | IP68 (for any diving work, water depth ≤3 meters) | ||

| Dimensions | See table below | ||

| Nominal pressure | See table below | ||

| Media type | Water, seawater, sewage, alcohol, various oils and other single, uniform and stable liquids that can conduct ultrasonic waves | ||

| Medium turbidity | ≤20000ppm and small bubble content | ||

| Pipe lining | None | ||

| Signal cable | SV75-2 type four-core special shielded cable can be extended to 500 meters. When wiring, the cable should be added with a metal sleeve to increase anti-interference. Pay attention to the cable not running in parallel with high-voltage cables and try to avoid interference sources such as frequency converters. | ||

Sanitary pipe sensor dimensions:

| DN(mm) | Rated pressure (MPa) | Material | Overall dimensions mm | |||

| L | H | D | C | |||

| 25 | 4 | Stainless steel | 300 | 282 | 51 | 19 |

| 40 | 300 | 300 | 74 | 23 | ||

| 50 | 300 | 310 | 84 | 24 | ||

| 65 | 350 | 330 | 100 | 28 | ||

| 80 | 400 | 345 | 114 | 30 | ||

| 100 | 450 | 365 | 128 | 31 | ||

Material stainless steel/carbon steel optional.

| DN(mm) | Rated pressure (MPa) | M type pipe section sensor | Standard pipe sensor | Flange Size | |||||

| L1 | L2 | D | D1 | D2 | f | O-N | Flange thickness | ||

| 15(m type) | 1.6 | 320 | 95 | 65 | 45 | 2 | 14×4 | 14 | |

| 20(m type) | 360 | 105 | 75 | 55 | 2 | 14×4 | 16 | ||

| 25(m type) | 390 | 115 | 85 | 65 | 3 | 14×4 | 18 | ||

| 32(m type) | 450 | 140 | 100 | 76 | 3 | 18×4 | 18 | ||

| 40(m type) | 500 | 150 | 110 | 84 | 3 | 18×4 | 20 | ||

| 20 | 195 | 105 | 75 | 55 | 2 | 14×4 | 16 | ||

| 25 | 225 | 115 | 85 | 65 | 3 | 14×4 | 18 | ||

| 32 | 230 | 140 | 100 | 76 | 3 | 18×4 | 18 | ||

| 40 | 245 | 150 | 110 | 84 | 3 | 18×4 | 20 | ||

| 50 | 200 | 160 | 125 | 100 | 3 | 18×4 | 22 | ||

| 65 | 210 | 180 | 145 | 120 | 3 | 18×4 | 24 | ||

| 80 | 225 | 195 | 160 | 135 | 3 | 18×8 | 24 | ||

| 100 | 250 | 215 | 180 | 155 | 3 | 18×8 | 26 | ||

| 125 | 270 | 245 | 210 | 185 | 3 | 18×8 | 28 | ||

| 150 | 300 | 280 | 240 | 210 | 3 | 23×8 | 28 | ||

| 200 | 370 | 335 | 295 | 265 | 3 | 23×12 | 30 | ||

| 250 | 450 | 405 | 355 | 320 | 3 | 25×12 | 32 | ||

| 300 | 500 | 460 | 410 | 375 | 4 | 25×12 | 32 | ||

| 350 | 550 | 520 | 470 | 435 | 4 | 25×16 | 34 | ||

| 400 | 600 | 580 | 525 | 485 | 4 | 30×16 | 38 | ||

| 400 | 1.0 | 600 | 565 | 515 | 482 | 4 | 25×16 | 30 | |

| 450 | 700 | 615 | 565 | 532 | 4 | 25×20 | 30 | ||

| 500 | 800 | 670 | 620 | 585 | 4 | 25×20 | 32 | ||

| 600 | 1000 | 780 | 725 | 685 | 5 | 30×20 | 36 | ||

| 700 | 1100 | 860 | 810 | 775 | 5 | 24×25 | 32 | ||

| 800 | 1200 | 975 | 920 | 880 | 5 | 24×30 | 32 | ||

| 900 | 1300 | 1075 | 1020 | 980 | 5 | 24×30 | 34 | ||

| 1000 | 1400 | 1175 | 1120 | 108 | 5 | 28×30 | 36 | ||

More Featured Heat Meters/Flow Meters

In addition to Ultrasonic Heat Meters, Electromagnetic Heat Energy Meters are also commonly used Heating and Cooling instruments.

- Top 3 Flow Meters for PVC Pipes

- Industrial Pressure Transmitters: 7 Sensor Principles and 4 Main Types!

- Pipe Flow vs Pressure – Relationship & Calculate Tools

- Top 4 Types of Pipeline Flow Meters-DN6~DN1000~DN6000

- Flow Measurement 101

Ultrasonic heat meter is an instrument that measures flow rate through ultrasonic method and displays the heat energy released or absorbed by water flowing through the heat exchange system. Compared with mechanical heat meters, ultrasonic heat meters have the advantages of easy maintenance, low comprehensive use cost, and good measurement reliability. They are widely used in water conservancy testing, heating systems, industrial production, commercial measurement and other fields.

We at Sino-Inst are manufacturers of ultrasonic flow meters and ultrasonic heat meters. The ultrasonic heat meters supplied by us are widely exported to various countries. Including the United States, the United Kingdom, Australia, etc.

If you need to purchase an ultrasonic heat meter or have related technical questions, please feel free to contact us!

Ultrasonic Heat Meters/Energy Meters| Inline&Clamp-on Meters

Ultrasonic Heat Meters have a heat accumulation function and are used to measure the thermal energy consumed in heating systems or chilled water. The ultrasonic flow meter is equipped with a pair of platinum resistors temperature sensor . And the international standard thermal exact value heat calculation formula (exact difference method) can be used to achieve the measurement of cooling capacity/heat.

Product SKU: Ultrasonic Heat Meters/Energy Meters | YFM-100 Series

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 300

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)