The Z Series Coriolis Liquid Mass Flow Meter utilizes a straight tube construction, resulting in minimal pressure loss. The sensor is compact and lightweight.

A straight Coriolis flow tube includes a reference tube, which serves as a secondary flow tube and also serves as a mounting point for the sensor and drive coil. The reference tube is characterized by its ability to bend when vibrating in the direction opposite to the flow tube. When the flow tube moves downward, the reference tube moves upward. Sino-Inst’s reference tube elastic design ensures the measurement system remains balanced in both no-flow and flowing conditions.

Features of Coriolis Liquid Mass Flow Meter

- Ability to directly measure the mass flow of fluid (this is of great significance for energy metering and production process detection and control, such as chemical reactions);

- High measurement accuracy (measurement accuracy can be guaranteed to be 0.1%~0.5%);

- The measurable ratio is relatively large, and the measurable ratio that generally guarantees basic accuracy is 10:1 or 20:1.

- Wide range of applications. In addition to normal fluid measurement, it can also measure industrial media that are difficult to measure with general fluid measurement instruments. Such as high-viscosity fluids, various slurries, suspensions, etc.;

- The density, temperature, and other parameters of the measured medium can be measured online, and the concentration of solutes in the solution can be derived from this.

- The installation requirements are not high, and there are no special requirements for the upstream and downstream straight pipe sections.

- Reliable operation and low maintenance rate;

Benefits of a Straight Tube Construction

Comparison between Straight and Bent Tubes

Straight measuring tubes are generally smaller in size and less prone to gas accumulation. However, due to their high vibration system stiffness, high resonant frequency, and extremely small phase difference of microseconds, processing electrical signals is more difficult. To prevent excessive resonant frequency, the tube wall must be thin, resulting in poor wear and corrosion resistance.

The curved tube has a lower vibration system stiffness, a lower resonant frequency, and a phase difference of milliseconds, making electrical signal processing easier. Furthermore, thicker tube walls can be used. Consequently, they offer better wear and corrosion resistance.

However, due to the complex shape of the curved tube, debris and gas can easily accumulate, causing additional errors. Furthermore, the curved tube is larger in size.

| Requires a mounting bracket. | |

| Straight tube; | Bent pipe; |

| Low pressure drop; | High pressure loss; |

| No clogging when measuring slurries; | Prone to clogging; |

| Easy to purge and clean; | Difficult to purge and clean; |

| For diameters smaller than DN50, no mounting bracket is required; flange connections can withstand deadweight. | Requires mounting bracket. |

Technical Specifications

| Density (liquid) measurement range and accuracy: | Measuring range: 0.3~3.000g/cm3; Measuring accuracy: ±0.002g/cm3; |

| Temperature measurement range and accuracy: | Measurement range: -50~200℃; Measurement accuracy: ±1℃; |

| Working temperature of the measured medium: | -50℃~200℃; |

| Applicable ambient temperature: | -40℃~60℃; |

| Material: | Measuring tube 316L, shell 304; |

| Working pressure: | 0~4.0MPa; 10MPa can be customized; Note: The actual withstand pressure of the sensor is different for each specification, here is just the standard withstand voltage. |

| Explosion-proof mark: | Ex d [ia]ⅡC T6 Gb; |

Sensor specifications, measuring range, and zero point stability

| Model | Diameter mm | Flow range kg/h | Zero point stability kg/h |

| Z-008Z | 8 | 0~960~1440 | 0.144 |

| Z-010Z | 10 | 0~1500~2250 | 0.225 |

| Z-015Z | 15 | 0~3000~4500 | 0.45 |

| Z-020Z | 20 | 0~6000~9000 | 0.9 |

| Z-025Z | 25 | 0~9600~14400 | 1.44 |

| Z-032Z | 32 | 0~18000~27000 | 2.7 |

| Z-040Z | 40 | 0~30000~45000 | 4.5 |

| Z-050Z | 50 | 0~48000~72000 | 7.2 |

Note:

The flow range gives two parameters, the middle parameter is the standard flow range.

Generally, factory inspection is carried out according to this range. It is also recommended that users select instruments within this range.

The latter parameter is the upper limit flow range that ensures stable operation of the sensor.

Flow (liquid) measurement accuracy:

| Flowmeter accuracy | Measurement error | Repeatability |

| 0.10% | ±0.1% ±(zero point stability/measured value)% | 1/2 measurement error% |

| 0.15% | ±0.15% ±(zero point stability/measured value)% | 1/2 measurement error% |

| 0.20% | ±0.2% ±(zero point stability/measured value)% | 1/2 measurement error% |

Coriolis Liquid Mass Flow Meter Applications

The characteristics of the straight tube mass flow meter determine that the flow meter can be widely used in the following fields:

Hygienic Mass Flow Meter

Sanitary mass flowmeter food industry, such as dissolved gas beverages, health drinks, and other fluids

Straight tube mass flowmeters can be customized for the sanitary industry. For example, dissolved gas beverages, health drinks, and other fluids.

Adopting new sanitary lining materials and lining processes, it meets the sanitary requirements of the food industry.

At the same time, stainless steel clamps are used for connection. It is convenient for the rapid disassembly and cleaning of the flowmeter, so that the flowmeter is not easily contaminated during use. And it can effectively prevent the accumulation of measured fluid residues in the measuring tube.

It can be widely used in the sanitary field of the production and manufacturing process of foods and pharmaceuticals such as mineral water, soy sauce, jam, beer, juice, rice wine, milk, etc.

Coriolis Liquid Mass Flow Meter working principle

The mass flow sensor consists of a measuring tube, a measuring tube drive device, a position detector, a supporting structure, a temperature sensor, a housing, and other parts.

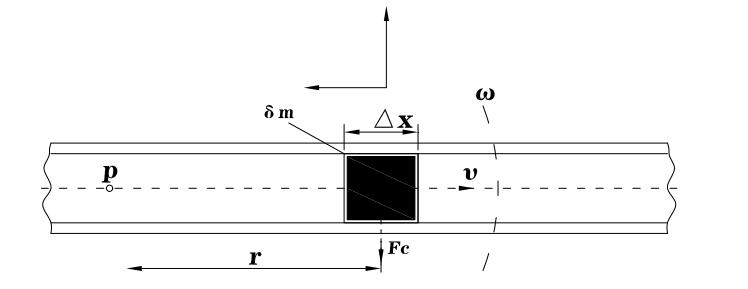

When a particle in a tube that rotates around a fixed point P (rotation center) moves toward or away from the rotation center, an inertial force will be generated. The principle is shown in the figure:

In the figure, a particle with a mass of δm moves to the right in the pipe at a uniform speed υ. The pipe rotates around a fixed point P at an angular velocity ω.

At this time, the particle will obtain two acceleration components:

- Normal acceleration αr (centripetal acceleration), whose magnitude is equal to ω2r and its direction is toward point P.

- Tangential acceleration αt (Coriolis acceleration), whose magnitude is equal to 2ωυ and its direction is perpendicular to αr.

The force generated by the tangential acceleration is called the Coriolis force. Its magnitude is equal to Fc=2ωυδm. In the figure, the fluid δm=ρA×ΔX. Therefore, the Coriolis force can be expressed as:

ΔFc=2ωυ×δm=2ω×υ×ρ×A×ΔX=2ω×δqm×ΔX

Where A is the cross-sectional area of the pipe.

δqm=δdm/dt=υρA

For a specific rotating pipe, its frequency characteristics are certain, and ΔFc depends only on δqm. Therefore, the mass flow rate can be measured by directly or indirectly measuring the Coriolis force. The Coriolis principle mass flowmeter works according to the above principle.

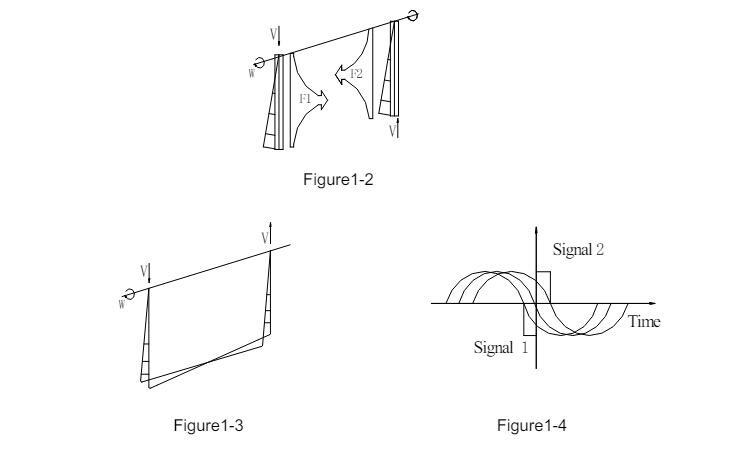

The actual flow sensor does not realize rotational motion, but instead uses pipe vibration. The principle diagram is shown in Figure .

The two ends of a curved pipe are fixed. A vibration force (according to the resonant frequency of the pipe) is applied to the pipe at the middle position of the two fixed points. It is made to vibrate with its natural frequency ω around the fixed point as the axis.

When there is no fluid flowing in the pipe, the pipe is only affected by the external vibration force. The two halves of the pipe vibrate in the same direction and there is no phase difference.

When there is fluid flowing, it is affected by the Coriolis force Fc of the medium particles flowing in the pipe (the Coriolis forces F1 and F2 in the two halves of the pipe are equal in magnitude and opposite in direction (Figure 1.2). The two halves of the pipe twist in opposite directions, resulting in a phase difference (Figure 1.3, Figure 1.4). This phase difference is proportional to the mass flow rate.

The design of the sensor is to convert the measurement of the Coriolis force into the measurement of the phase time difference on both sides of the vibrating tube. This is the working principle of the Coriolis mass flowmeter.

Read more about: Coriolis Mass Flow Meter Technology

More Flow Measurement Solutions

- Hydrogen Flow Meters for Mass and Volume Flow

- Beverage Flow Meters for Flow Monitoring and Quantitative Filling

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Application Case: Mass Flow Meter Measures Lime Slurry Flow and Density

- Guide: Types of Mass Flow Meters

- Bidirectional Flow Meters | Electromagnetic, Ultrasonic, Mass and Porous Orifice Flowmeter

- Mass Flow Rate and Volumetric Flow Rate: Key Differences and Conversion

- What Is the Difference Between Mass Flow Meter and Magnetic Flow Meter?

- Use and Maintenance of Coriolis Mass Flowmeters

- Thermal Mass Flow Meter Technology

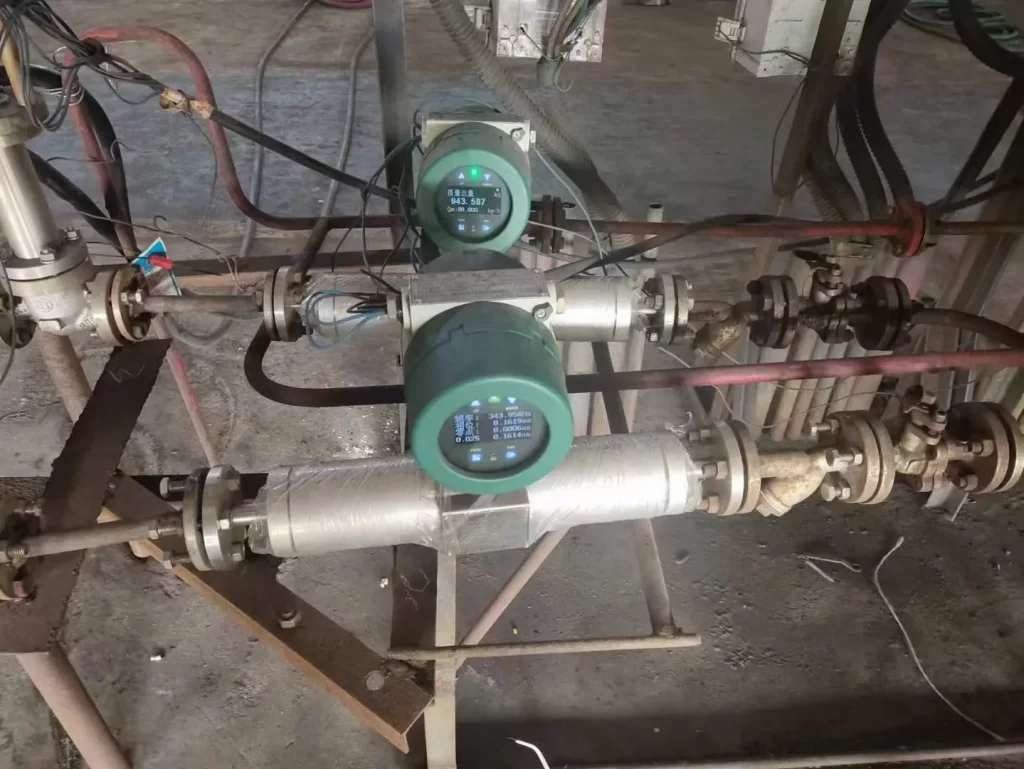

Sino-Inst Liquid Mass Flow Meters meet the requirements of level 0.15 (actually can reach more than 0.1). The range ratio is 1:20. Our straight tube mass flow meter has a straight tube structure with low pressure loss. The sensor is small and light.

Mass flow meters with straight tube structures are not easy to deposit materials. They are easy to clean. And they are not easy to accumulate gas. Compared with other structures, Coriolis mass flow meters will not be blocked for measuring slurry. They are easy to purge and clean. And small-diameter installation does not require a bracket, and flange or threaded connection can bear its own weight.

Z Series Straight Tube Coriolis Liquid Mass Flow Meter of Sino-Inst efficiently meets the user’s mass flow measurement needs. And the price is advantageous! If you need to purchase or have technical questions, please contact our engineers!

Z Series Coriolis Liquid Mass Flow Meter - Straight Tube

The Z Series Coriolis Liquid Mass Flow Meter utilizes a straight tube construction, resulting in minimal pressure loss. The sensor is compact and lightweight.

Product SKU: Z Series Straight Tube Coriolis Liquid Mass Flow Meter

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 3999

Price Valid Until: 2029-09-09

Product In-Stock: PreOrder

5

-1.jpg)