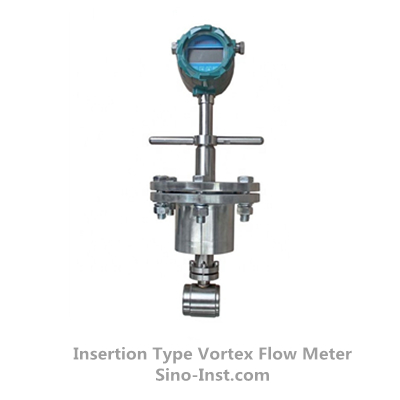

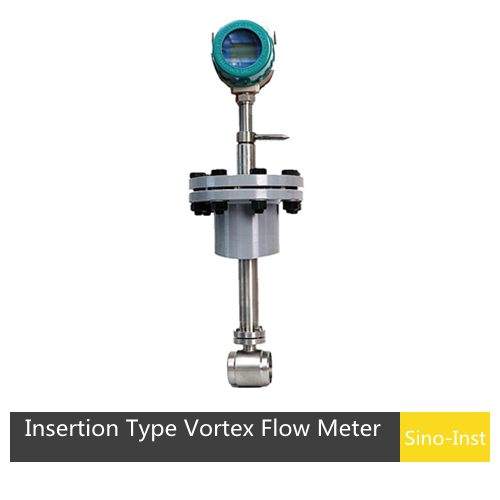

The Insertion Vortex Flow Meter is designed for large-diameter pipes of DN200 (8 inches) and above. Users can install and remove the vortex sensor without shutting down the entire operating system.

Customers can measure the volumetric or mass flow rate of gases, liquids, or steam using our powerful vortex flow meters. Insertion vortex flow meters offer a more reliable and cost-effective mass flow measurement solution.

| Diameter | DN200~DN3000mm |

| Accuracy | ±1.5%~±2.5% |

| Temp. range | -50~+400℃ |

| Nominal pressure | PN25, PN40 (customized) |

| Protection | IP67 |

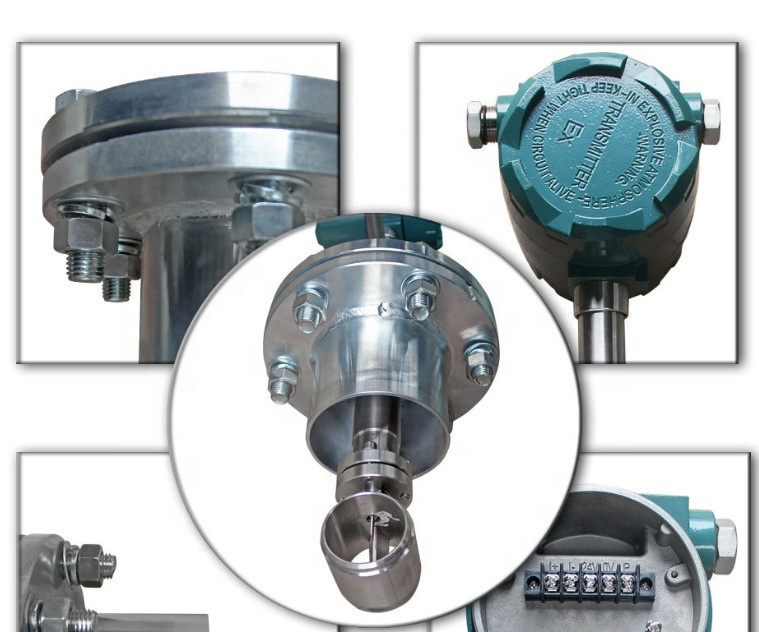

| Explosive-proof | ExdIIBT4-T6, ExiaIICT4-T6 |

Features

Specifications

| Nominal Diameter (mm) | 200~2000 |

| Instrument Material | 1Cr18Ni9Ti |

| Nominal Pressure (MPa) | PN1.6Mpa;PN2.5Mpa |

| Measured Medium Temperature (°C) | -40~+400℃ |

| Environmental Conditions | Ambient temperature: -10~+55℃, relative humidity: 5%~90%, atmospheric pressure: 86~106kPa |

| Accuracy Class | ±2.5% of reading |

| Range Ratio | 1:10;1:15; |

| Drag Loss Coefficient | Cd<2.6 |

| Output Signal | Sensor: +24VDC Transmitter: +24VDC Field display type: Instrument equipped with a 3.2V lithium battery |

| Power Supply | Sensor: +24VDC Transmitter: +24VDC Field display type: Instrument equipped with 3.2V lithium battery |

| Signal Transmission Line | KVVP3×0.3 (three-wire system), 2×0.3 (two-wire system) |

| Transmission Distance | ≤500m |

| Signal Line Interface | Female thread M20×1.5 |

| Explosion-proof Rating | ExdIIBT6 |

| Protection Class | IP65 |

| Permissible Vibration Acceleration | 1.0g |

Insertion Vortex Flow Meter Datasheet

Applications

Insertion vortex flow meters, due to their high accuracy and wide applicability, have been applied to large-diameter pipelines in multiple fields:

Oil and Gas: Used to measure the flow rate of oil and gas, ensuring the safety and efficiency of the production process.

Chemical Industry: Precise control of raw material flow rate is crucial in chemical reaction processes.

Water Treatment: Used to monitor and control water flow rate, ensuring stable water quality and quantity.

Food and Beverage: In food processing, flow meters are used to monitor the flow rate of raw materials and finished products, ensuring product quality.

Order Guide

In addition to regular products, we support customization

| Mode | Interpretation | ||||||

| SI-3304 | ¨ | ¨ | ¨ | ¨ | ¨ | ¨ | insert vortex flow meter |

| Connection mode | 1 | Flange connection(for full tube vortex flowmeter) | |||||

| 2 | Flange clamping(for full tube vortex flowmeter) | ||||||

| Measured medium | 1 | Liquid | |||||

| 2 | General gas | ||||||

| 3 | Compressed air | ||||||

| 4 | Steam | ||||||

| inside nominal diameter | 200 | Intelligent: Lithium battery power supply,status display(Dual power supply, pulse output optional) | |||||

| 300 | 300mm | ||||||

| 400 | 400mm | ||||||

| 500 | 500mm | ||||||

| 600 | 600mm | ||||||

| 700 | 700mm | ||||||

| 800 | 800mm | ||||||

| 900 | 900mm | ||||||

| 1000 | 1000mm | ||||||

| 1100 | 1100mm | ||||||

| 1200 | 1200mm | ||||||

| 1300 | 1300mm | ||||||

| 1400 | 1400mm | ||||||

| xx | xxmm | ||||||

| Compensation | N | Uncompensated(suitable for volume flow measurement occasions) | |||||

| T | Temperature compensation(suitable for saturated steam) | ||||||

| P | Pressure compensation(suitable for saturated steam) | ||||||

| F | Temperature and pressure compensation((suitable for superheated steam and compressed air) | ||||||

| Output type | N | Sensor type:24VDC power supply, output three-wire pulse signal | |||||

| A | Transmitter type:24VDC power supply,Output current signal 4~20mA | ||||||

| B | Transmitter type:24VDC power supply, Output current signal 4~20mA | ||||||

| C1 | Intelligent:24VDC power supply,status display、output 4-20mA(pulse output optional) | ||||||

| C2 | Intelligent:24VDC power supply,status display、output two-wire system 4-20mA HART communication、(pulse output optional) | ||||||

| C3 | Intelligent:24VDC power supply,status display、RS485 communication、(Dual power supply, pulse output optional) | ||||||

| accuracy class | 2 | 2.5 level | |||||

| 3 | Explosion-proof type, ExdIICT6 | ||||||

| material quality | S | 304 stainless steel | |||||

| L | 316(L)stainless steel(Customized,long supply cycle) | ||||||

| material quality | N | Non-explosion-proof type | |||||

| E | Explosion-proof type,ExdIICT6 | ||||||

| Pressure grade | P | Actual pressure grade(customization for high pressure, long supply cycle) | |||||

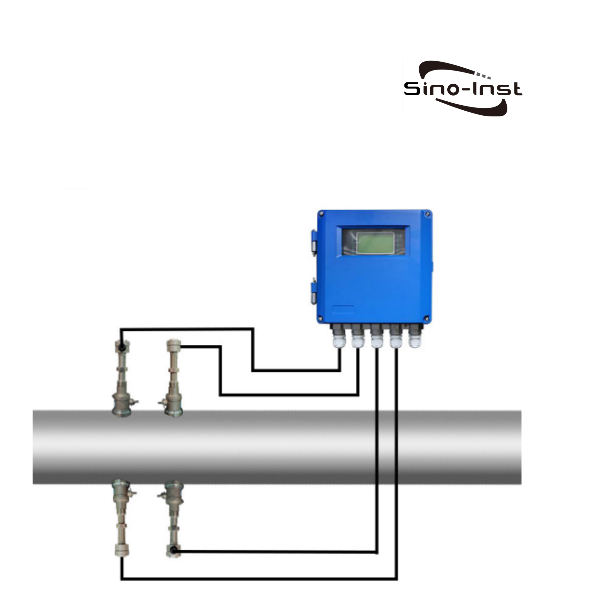

Installation Guide

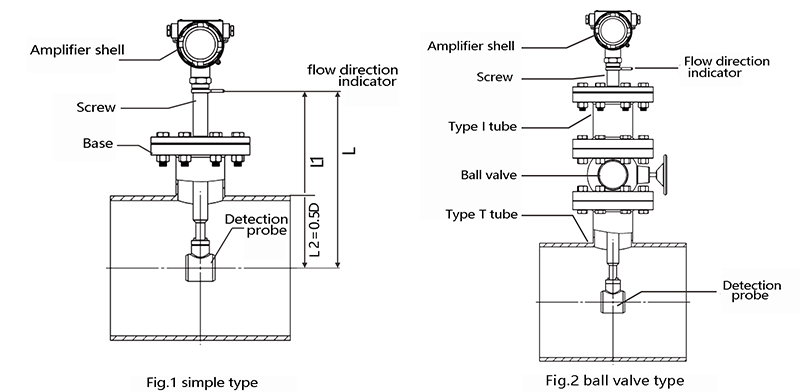

Installation steps for an insertion-type vortex flow meter:

- Use gas welding to create a circular hole slightly smaller than φ100mm in the pipeline. Clean the area around the hole to ensure smooth probe rotation.

- Weld the manufacturer’s flange short pipe to the circular hole in the pipeline, ensuring the flange axis is perpendicular to the pipeline axis.

- Install the ball valve and sensor onto the welded flange.

- Adjust the screw to ensure the insertion depth meets requirements (ensuring the probe’s center axis coincides with the pipeline’s center axis). The fluid flow direction must be consistent with the indicator arrow on the direction indicator.

- Tighten the screws on the gland evenly. (Note: The tightness of the gland determines the instrument’s sealing performance and whether the screw can rotate.)

- Check that all steps are completed correctly. Slowly open the valve to observe for leaks (pay special attention to personal safety). If leaks are found, repeat steps 5 and 6.

- Ensure there is a flow meter upstream of at least 15D and downstream of at least 5D of straight pipe.

Related Products

More Technical Support and Cases

The insertion vortex flow meter is a new type of flow meter developed based on the principle of liquid vibration. It is widely used for fluid measurement in industries such as petroleum, chemical, metallurgy, and papermaking. It is unaffected by the temperature, pressure, viscosity, and composition of the medium, and is non-clogging, non-jamming, and resistant to scaling. It is also resistant to high temperatures and pressures, safe, and explosion-proof, making it suitable for harsh environments.

Sino-Inst’s insertion vortex flow meter has no moving parts, ensuring high reliability, high accuracy, and a long service life. It can accurately measure the instantaneous and cumulative flow of liquids over a wide flow range. We support customized measurement parameters. If you need to select a flow measurement solution for large-diameter pipelines, please feel free to contact us.

Insertion Vortex Flow Meter-Accurate & Reliable | Sino-Inst

The Insertion Vortex Flow Meter is designed for large-diameter pipes of DN200 (8 inches) and above. Users can install and remove the vortex sensor without shutting down the entire operating system.

Product SKU: SI-3304 Insertion Vortex Flow Meter

Product Brand: Sino-Inst

Product In-Stock: InStock

5

-1.jpg)