For sustainable development strategies, companies usually install industrial wastewater treatment equipment. Install monitoring instruments such as Sewage Flow Meters and Effluent Flow Meters to monitor wastewater treatment and discharge.

In this blog post, we’ll dig into what sewage and effluent flow meters are!! It will give clients a broader perspective of wastewater flow measurement.

What Is a Sewage Flow Meter?

A sewage flow meter is a device used to measure the flow of untreated or partially treated wastewater, commonly referred to as sewage. This type of water typically contains solids, suspended particles, grease, oil, and other contaminants. It is highly variable in consistency, making accurate flow measurement a challenge.

Sewage flowmeter is composed of water level flow sensor (probe) and upper computer (terminal) and communication cable, which is used to measure the volume flow of various sewage in the pipeline and in the channel.

What Is an Effluent Flow Meter?

An effluent flow meter measures the flow of treated wastewater—commonly known as effluent—discharged from industrial or municipal treatment facilities.

Unlike raw sewage, effluent has gone through various purification stages and is usually much cleaner. Nevertheless, it may still contain residual contaminants, nutrients, or chemicals that need to be monitored closely.

Measurement challenges

- The measuring medium is corrosive liquid;

- The working environment is harsh, and the stability and accuracy of the product are high;

Solution advantages

- Ability to measure various types of liquids, including conductive and non-conductive, corrosive and non-corrosive liquids;

- High product accuracy, good stability, and low power consumption.

- Various installation forms, and can record historical data.

- Products can be customized according to actual working conditions.

Types of Sewage and Effluent Flow Meters

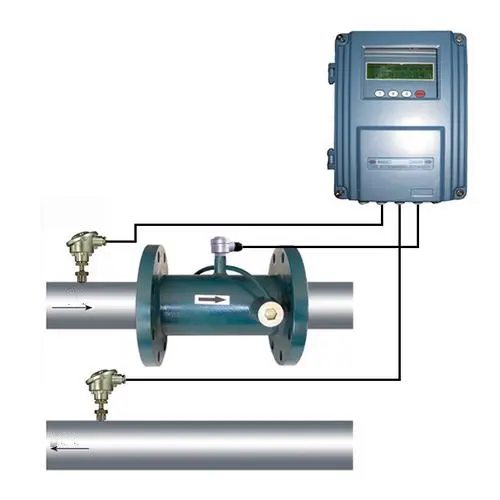

1. Electromagnetic Flow Meters (Mag Meters)

Mag meters are widely used for both sewage and effluent applications due to their non-intrusive, obstruction-free design. They work based on Faraday’s Law of Electromagnetic Induction and require the fluid to be conductive.

Advantages:

- No moving parts

- Excellent for dirty or corrosive fluids

- High accuracy (±0.5% or better)

- Minimal maintenance.

- They don’t obstruct fluid flow hence doesn’t reduce fluid pressure

- High pressure type can be customized: 16MPa, 25MPa, 42MPa.

- Gives accurate results of waste water measurement

- High-reliability rate since it gives standard performance for a very long time

- Can handle greasy fluids that even contain suspended solids

- The fluids measurement is independent of density, viscosity, pressure and temperature

- Electronic mag flow meter with 4-20mA output and pulse output

- Digital flow indicator to show liquid total flow and flow rate

- Option with various power supply, such as 220V AC, 24V DC and battery

Disadvantages:

- Requires power supply

- Only works with conductive fluids

- The liquid must fit into the pipe for accurate results.

- Gas and air bubbles can cause errors.

2. Ultrasonic Flow Meters

Ultrasonic meters use sound waves to measure flow. There are two types: transit-time and Doppler. Doppler meters are particularly useful for sewage with suspended solids.

Advantages:

- Non-invasive (clamp-on options)

- No pressure drop

- Suitable for retrofits

Disadvantages:

- May be affected by air bubbles or varying flow profiles

- Accuracy can vary based on installation conditions

Of course, in addition to the above two types of flow meters, we can also customize other types of flow meters and Flow switches according to actual measurement parameters.

Installation and Maintenance Tips

Follow Manufacturer Guidelines: Always adhere to straight pipe requirements, grounding needs, and sensor alignment.

Avoid Air Pockets: Air bubbles can distort readings. Ensure the pipe is always full or install air release valves.

Regular Calibration: While many meters are low-maintenance, periodic calibration checks ensure long-term accuracy.

Sensor Cleaning: In sewage applications, inspect and clean sensors to prevent buildup or fouling.

Monitor Outputs: Use remote monitoring or SCADA systems to track performance and detect anomalies in real-time.

More Flow Measurement Solutions

- Powder/Dry Material Level Switches – Product List and Selection

- Rotameters: Excellent Choice for Flow Measurement in Various Gases

- Flow Meter Selection Guide: Starting from Measurement Conditions

- 4 Types of Manifolds for Pressure Transmitters

- Industrial Water Pressure Measurement and Monitoring

- Choose Digital Water Pressure Switch for Better Control

- What Is Temperature Compensation in a Pressure Transmitter?

- Case Study – Mass Flow Meter For Slurry

- LNG and CNG Flow Measurement

The world is increasingly focused on sustainable water management. Sewage flow meters and effluent flow meters are nitpicking tools in that mission.

Choosing the right flow meter technology, installing it properly, and maintaining it regularly will ensure accurate data collection and peace of mind for years to come.

If you’d like help selecting the right sewage or effluent flow meter for your specific application, or want to learn more about the latest models on the market, feel free to reach out to Sino-Inst, a professional manufacturer and supplier of flow measurement technology.

-1.jpg)