80GHz Series Radar Level Transmitters refers to frequency modulated continuous wave (FMCW) radar products operating at 76-81GHz. Also called frequency modulated continuous wave radar level meter. The maximum range of non-contact measurement can reach 150m, and the blind zone can be 8-10 cm.

The main advantages of 80GHz Series Radar Level Transmitters are smaller emission angles, more concentrated energy, stronger echo signals, stronger penetration, and higher measurement accuracy. Supports measurement of water level, acid and alkali liquid levels, coal powder, cement, grain and other material levels.

Features

Featured 80G radar level transmitter models and parameters

FMW11S

- Measuring medium: Liquid

- Measuring range: 0.1m~10m

- Process connection: Thread G¾”A / ¾”NPT; Flange ≥DN25

- Process temperature: -40~100℃

- Process pressure: -0.1~1.6 MPa

- Antenna size:21mm lens antenna

- Antenna material: PTFE

- Accuracy: ±5mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle:14°

- Power:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol/RS485/Modbus protocol

FMW11

- Measuring medium: Liquid

- Measuring range: 0.1m~30m

- Process connection: Thread G½”A /1 ½”NPT; Flange ≥DN40

- Process temperature: -40~80℃/ -40~100℃

- Process pressure: -0.1~0.3 MPa

- Antenna size:32mm lens antenna

- Antenna material: PTFE

- Accuracy: ±2mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 8°

- Power:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol/RS485/Modbus protocol

FMW12

- Measuring medium: Liquid

- Measuring range: 0.1m~30m

- Process connection:Flange ≥DN40; Thread can be customized;

- Process temperature: -40~120℃

- Process pressure: -0.1~1.6 MPa

- Antenna size:32mm lens antenna

- Antenna material: PTFE

- Accuracy: ±2mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 8°

- Power:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol/RS485/Modbus protocol

FMW13

- Measuring medium: Liquid

- Measuring range: 0.2m~30m/0.3~150m

- Process connection: Flange ≥DN80 /Thread G3 A

- Process temperature: -40~150℃; -40-130℃(Athread)

- Process pressure: -0.1~1.0 MPa

- Antenna size:76mm lens antenna

- Antenna material: PTFE

- Accuracy: ±2mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 3°

- Power:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol/RS485/Modbus protocol

FMW13S

- Measuring medium: Liquid

- Measuring range: 0.2m~30m/0.3~150m

- Process connection:Flange ≥DN80 /Gantry frame

- Process temperature: -40~80℃

- Process pressure: -0.1~0.3 MPa

- Antenna size:76mm lens antenna

- Antenna material: PTFE

- Accuracy: ±2mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 3°

- Power:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol/RS485/Modbus protocol

FMW13G

- Measuring medium: Liquid

- Measuring range: 0.1m~30m/0.3m~150m

- Process connection:Flange ≥DN80

- Process temperature: -40~280℃

- Process pressure: -0.1~2.5 MPa

- Antenna size:76mm lens antenna

- Antenna material: PEEK

- Accuracy: ±2mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 6°

- Power:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol/RS485/Modbus protocol

FMW14

- Measuring medium: Liquid

- Measuring range: 0.1m~30m

- Process connection:Flange ≥DN50

- Process temperature: -40~200℃

- Process pressure: -0.1~2.5 MPa

- Antenna size:44mm lens antenna

- Antenna material: PTFE

- Accuracy: ±2mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 6°

- Power:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol/RS485/Modbus protocol

FMW15

- Measuring medium: Liquid

- Measuring range: 0.3m~30m

- Process connection:Flange ≥DN80

- Process temperature: -40~200℃

- Process pressure: -0.1~2.5 MPa

- Antenna size:76mm lens antenna

- Antenna material: PTFE

- Accuracy: ±2mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 3°

- Power:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol/RS485/Modbus protocol

FMW21

- Measuring medium: Solid

- Measuring range: 0.1m~30m/0.3~150m

- Process connection:Flange ≥DN80

- Process temperature: -40~150℃/-40~200℃

- Process pressure: -0.1~0.3 MPa

- Antenna size:76mm lens antenna

- Antenna material: PTFE

- Accuracy: ±5mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 3°

- Power:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol/RS485/Modbus protocol

FMW21S

- Measuring medium: Solid

- Measuring range: 0.1m~30m/ 0.3m~150m

- Process connection:Flange ≥DN80

- Process temperature: -40~80℃

- Process pressure: -0.1~0.3 MPa

- Antenna size:76mm lens antenna

- Antenna material: PE

- Accuracy: ±5mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 3°

- Power:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol/RS485/Modbus protocol

radar level transmitter working principle

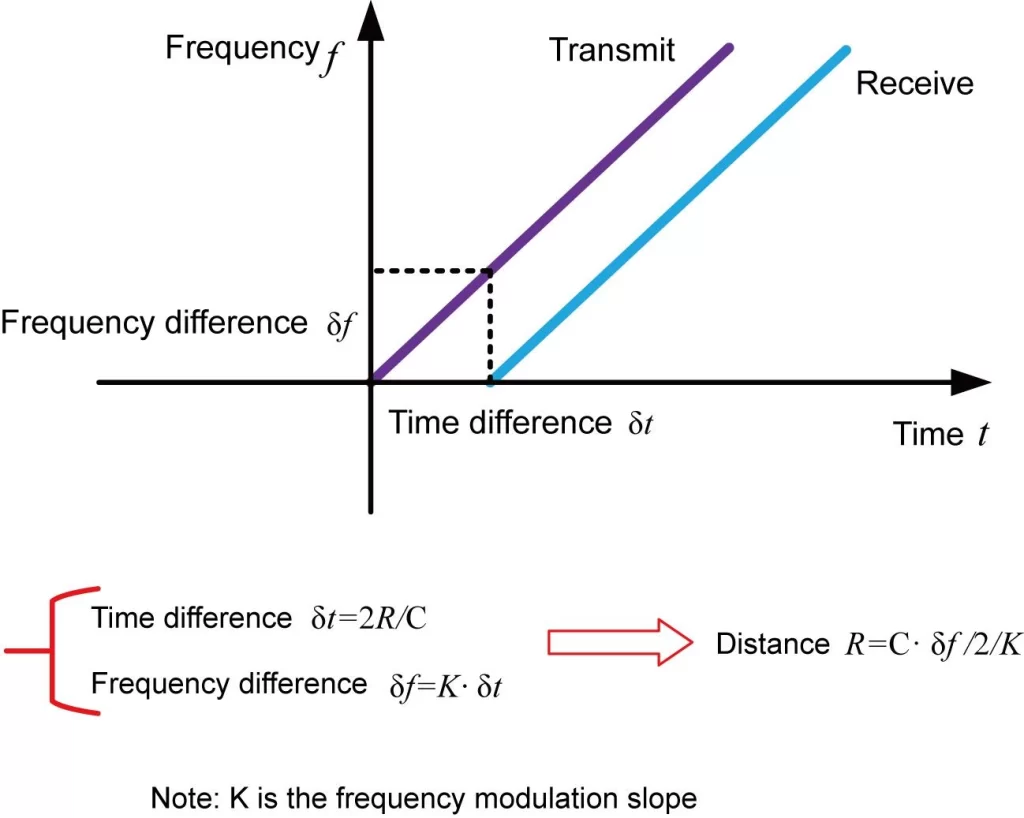

The general principle of the FM continuous wave radar level sensor is that the radar emits electromagnetic waves on the top of the tank, and the electromagnetic waves are received by the radar after being reflected by the medium.

The frequency difference δf between the received signal and the transmitted signal is proportional to the distance R from the surface of the medium:

R=C (speed)*δf (frequency difference)/2/K (frequency modulation slope).

Because the speed of light C and the frequency modulation slope K are known, the frequency difference δf can be estimated to obtain the distance R from the radar installation position to the material surface, and then through the known total height of the tank, subtract the spatial distance from the radar to the material surface (referred to as Empty height) to get the height of the material level.

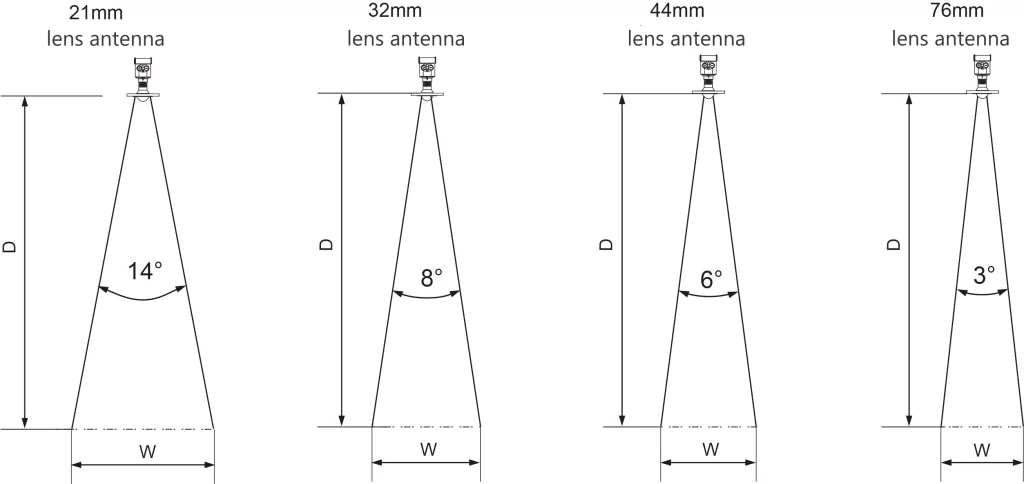

Beam angle and antenna of radar level transmitter

The beam angle is the beam angle when the radar wave energy density reaches half of its maximum value (3dB width). Microwaves emit signals outside the beam range and can be reflected by interference objects.

| Lens antenna diameter | Φ21mm Lens antenna | Φ32mm Lens antenna | Φ44mm Lens antenna | Φ78mm Lens antenna |

| Beam angle | 14° | 8° | 6° | 3° |

The larger the antenna size, the smaller the beam Angle alpha, the less the interference echo will be generated.

For more accurate measurements, avoid installing any internal devices (such as limit switches, temperature sensors, bases, vacuum rings, heating coils, baffles, etc.) within the signal beam range.

80GHz Radar Level Transmitters Applications

80GHz Series Radar Level Transmitters can be said to be the most widely used level meter. Can be applied to water level, acid and alkali liquid level measurement. It can also be used for level measurement of coal powder, cement, grain and other materials. High temperature measurements of 400℃ and 1000℃ can also be customized.

Below are some applications of radar level gauges (liquid level gauges) in various scenarios compiled by our Sino-Inst based on many years of radar level measurement experience. For your reference to choose a suitable liquid level transmitter.

Steel industry

Production links: Coal coking: preparing coal bunkers, coke bunkers, gas holders, coal tar and crude benzene tanks;

Sintering plant: sinter material mixing warehouse, cold return ore, and pellet warehouse;

Ironmaking plant: ironmaking intermediate warehouse, blast furnace material level, etc.;

Working condition characteristics:

Measurement of solid materials, strong dust, low dielectric constant, long range.

Volatile crystallization of tar and crude benzene. High temperature and dust adhesion at the blast furnace material level.

Selection application:

Solid measurement is mainly based on high-frequency pulse radar level meters.

Guided wave radar level meters can be used for crude benzene and coal tar.

Coal industry

Production links: raw coal bunker, pulverized coal bunker, coal gangue storage level, coal washing pool.

Working condition characteristics: typical solid material measurement, strong dust, low dielectric constant, long range

Selection application: mainly high-frequency pulse radar level meter.

Cement industry

Production links: raw material warehouse, raw material homogenization warehouse, clinker warehouse, finished product warehouse, fly ash warehouse, raw coal warehouse, gypsum warehouse, cement slag warehouse

Working conditions characteristics: Typical solid material measurement, strong dust, low dielectric constant, long range.

Selection application: Mainly high-frequency pulse radar level meter.

Electric power industry, thermal power, hydropower, biopower generation

Production links: (thermal power) raw coal and pulverized coal silos, circulating pools, low and high water levels, limestone powder silos, ash hopper material levels, ash warehouses, slag silos, and desulfurization tower liquid levels;

Working condition characteristics:

Measurement of solid materials, strong dust, low dielectric constant, long range.

Low water level, high temperature and high pressure;

Desulfurization tower liquid level foam, water vapor, crystallization and spray interference;

Selection application:

The measurement of solid materials is mainly based on high-frequency pulse radar level meters;

For high and low water levels, guided wave radar is used;

Low-frequency radar level meters are commonly used for liquid levels in desulfurization towers;

Non-ferrous metallurgical industry: aluminum, nickel, zinc, titanium industry

Production links: (aluminum production) slurry tank, dissolution tank, flash kettle, post-dissolution tank, flocculation tank, settling tank, decomposition tank, alumina powder silo

Characteristics of working conditions: Various chemical reaction environments include factors such as high temperature, strong water vapor, stirring or corrosion.

Selection application:

For the influence of high-temperature water vapor, choose guided wave radar or low-frequency radar level meter with reference to factors such as corrosion, measuring range, stirring, hanging materials, etc.;

High-frequency radar level meters are still preferred for solid measurements.

Water conservancy industry

Application scope: Hydrological monitoring, flood control alarm, farmland irrigation

Characteristics of working conditions: long signal transmission, low power supply voltage, installation location affected by river embankments and dams. Radar waves with small beam angles are preferred.

Selection application: Select high-frequency radar level meter with MODBUS protocol

Food and pharmaceutical industry

Production links: edible oil tanks, soybean meal storage tanks

Characteristics of working conditions: Simple oil tank environment, or precision requirements, and antenna hygiene requirements in the pharmaceutical and food industries

Selection application:

For high-precision measurement environments, high-frequency radar level meters are preferred;

If there are hygienic requirements, you should choose an antenna with a sealed material that meets hygienic conditions;

Industrial industry: petrochemical industry, coal chemical industry

Production link:

Petrochemical industry: crude oil depot, gasoline tank, diesel tank, natural gas tank, etc.

Coal coke chemical industry: reference coal industry

Calcium carbide chemical industry: coal bunker, calcium carbide bunker, etc.

Working conditions characteristics:

Measurement of solid materials, strong dust, low dielectric constant, long range;

The measurement environment of various oil depots is simple and may have accuracy requirements;

There is pressure in the natural gas spherical tank and the dielectric constant is small;

There are oscillation interference echoes in gas counter measurements;

Various chemical reactors have different conditions;

Selection application:

The measurement of solid materials is mainly based on high-frequency pulse radar level meters;

For various oil depots and spherical tanks with accuracy requirements, high-frequency radar is preferred;

Gas cabinets that are prone to oscillation and interference signals also have limited options for high-frequency radar;

Chemical reactors are selected according to actual conditions and parameters;

Environmental protection and water treatment industry

Treatment links: water collection well, coarse grid, fine grid, biochemical reaction tank, mud flushing tank, sludge tank, well dissolved chemical tank;

Working conditions characteristics: Except for ultra-long ranges and narrow spaces such as water collection wells, other environments are relatively simple;

Selection application:

The water collection well can choose guided wave radar or high-frequency radar level meter according to the range requirements. Generally, ultrasonic liquid level meter is more commonly used in simple environments;

Semiconductor industry

Production link: Silica powder warehouse

Working conditions characteristics: very low dielectric constant, strong dust

Selection application: high frequency radar level meter

More Featured Level Measurement

The 80GHz Radar Level Transmitter has the characteristics of high measurement accuracy, wide application range, and non-contact measurement. It can be widely used in material level and liquid level measurement of various highly corrosive and high dust media.

Our Radar Level Transmitters from Sino-Inst use Frequency Modulated Continuous Wave (FMCW) technology and are suitable for measuring liquid levels and solids. Radar Level Transmitter is highly penetrating and suitable for high vapor and dust applications. The measurement is not affected by changes in the medium, nor by process conditions such as temperature, pressure, dust, etc. Supports Hart, Modbus and other protocols.

If you need to purchase 80GHz Radar Level Transmitters, or have related technical questions, please feel free to contact us.

Radar Level Transmitters-80GHz-Non-Contact Measurement

80GHz Series Radar Level Transmitters refers to frequency modulated continuous wave (FMCW) radar products operating at 76-81GHz. Also called frequency modulated continuous wave radar level meter. The maximum range of non-contact measurement can reach 150m, and the blind zone can be 8-10 cm.

Product SKU: Radar Level Transmitter-80GHz Series-High Accuracy

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 599

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)