Mass flow meters quantify the fluid’s mass to ascertain the flow rate, whereas magnetic flow meters utilize magnetic fields to gauge the flow of conductive fluids. Selecting between a mass flow meter and a magnetic flow meter depends on your specific application needs.

We’ll explore the key differences between mass flow meters and magnetic flow meters and then provide a detailed guide on how to install a mass flow meter.

Key Differences Between Mass Flow Meters and Magnetic Flow Meters

1. The Measurement Principle is different

Mass flow meter Measurement Principle

When seeking accuracy, mere volume measurements sometimes fall short. This is where mass flow meters come into play with their sophisticated capability to determine the actual mass of fluid traveling through a device with outstanding precision.

These instruments don’t settle for just measuring volume. They delve deeper into quantifying the very nature of the flowing substance, both liquids and gases alike. It’s this commitment to comprehending the fundamental characteristics of flow that distinguishes them as vital tools in various fields.

If we take into account Coriolis mass flow meters: these devices utilize the Coriolis effect for direct measurement of fluid mass flow and can even detect changes in its density. Read more about: Coriolis Mass Flow Meter Technology.

Alternatively, thermal mass flow meters rely on evaluating how much heat is transmitted from a heated element onto passing fluids – an indication revealing immense details about the rate at which mass flows past a point without being influenced by viscosity swings, pressure fluctuations, or varying densities.

Read more about: Thermal Mass Flow Meter Technology.

Magnetic Flow Meter Measurement Principle

A magnetic flow meter, also known as an electromagnetic flow meter, operates on the principle of electromagnetic induction to measure the flow rate of electrically conductive liquids.

Essentially, it consists of a non-intrusive flow tube equipped with electrodes and a magnetic field generated by coils. As the conductive fluid passes through this magnetic field, a voltage proportional to the flow rate is induced, which is then measured by the electrodes.

Read more about: Magnetic Flowmeter Technology.

2. Fluid Types

Mass Flow Meter

Mass Flow Meter Can measure both liquids and gases and is commonly used for applications involving multi-phase fluids or varying fluid properties (e.g., density, viscosity).

Magnetic Flow Meter

Only suitable for measuring conductive liquids, such as water, acids, and slurries. It cannot measure gases or non-conductive fluids like oils, hydrocarbons, or organic solvents.

3. Cost Performance

Both types of meters offer good cost performance, but the best choice depends on specific requirements. Mass flow meters provide long-term reliability for both liquid and gas measurements, while magnetic meters offer durability and accuracy for liquid measurements.

Of course, the overall price of a mass flow meter will be much higher than that of an electromagnetic flow meter.

4. The advantages of the mass flow meter and magnetic flow meter

The main advantages of mass flow meter:

- Direct Mass Flow Measurement: Mass flow meters measure the mass flow rate directly, without requiring temperature or pressure compensation. This provides accurate readings regardless of changing gas conditions.

- High Sensitivity: These meters are highly sensitive to low flow rates, making them ideal for applications where precise measurements of small gas flows are crucial, such as in environmental monitoring and leak detection.

- Wide Range of Applications: Thermal mass flow meters are suitable for a variety of gases, including air, nitrogen, hydrogen, and natural gas. Their versatility makes them valuable in industries such as pharmaceuticals, chemical processing, and HVAC.

- Cost Performance: With no moving parts, mass flow meters offer long-term reliability and low maintenance costs. This results in excellent cost performance over their operational lifetime.

The main advantages of magnetic flow meter:

- High Accuracy: Magnetic flow meters provide highly accurate flow measurements for conductive liquids, typically achieving an accuracy of ±0.5% of the flow rate. This precision is essential for applications requiring strict control, such as in water treatment and chemical manufacturing.

- No Moving Parts: Like mass flow meters, mag meters have no moving parts, which reduces maintenance needs and enhances durability. This design advantage ensures reliable operation over long periods.

- Wide Diameter Range: Magnetic flow meters can accommodate a wide range of pipe sizes, from small to very large diameters. This flexibility makes them suitable for diverse applications, from municipal water supply to industrial process control.

- Environmental Compatibility: Magnetic meters can measure the flow of aggressive chemicals, slurries, and other challenging fluids. Thanks to their robust construction and resistance to corrosion. This makes them ideal for harsh industrial environments.

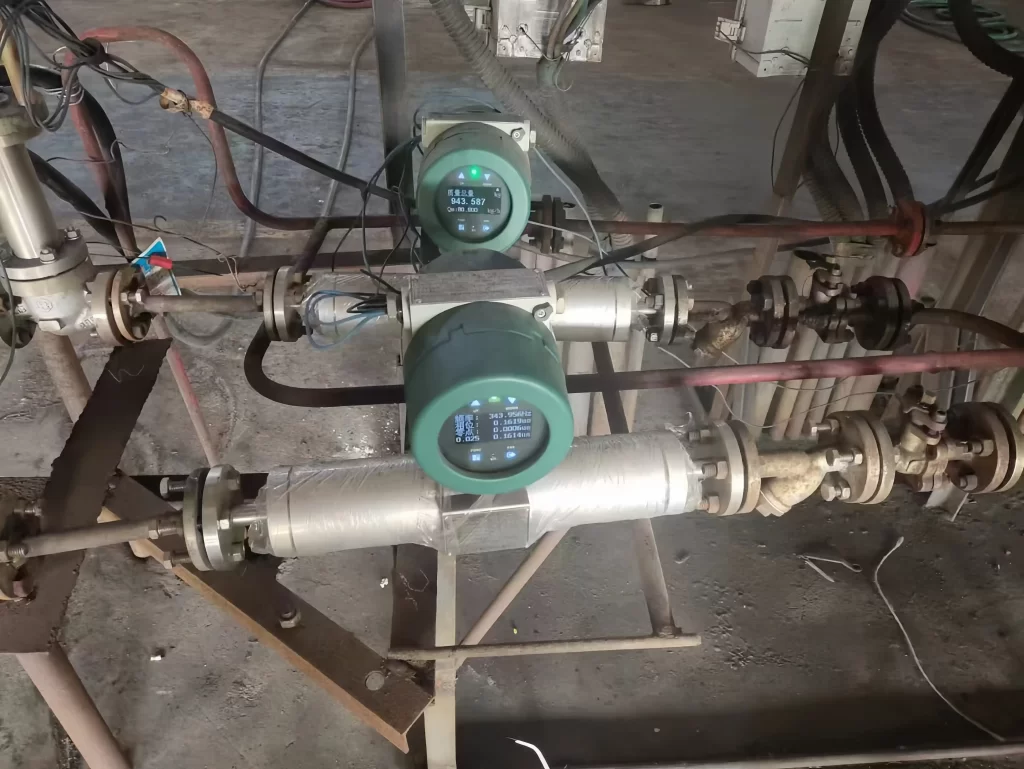

Installation Guideline: Mass Flow Meter Vs Magnetic Flow Meter

The installation requirements of electromagnetic flowmeters are higher than those of mass flowmeters. Electromagnetic flowmeters require straight pipe sections before and after installation. Mass flowmeters do not have such requirements.

For detailed installation requirements and installation steps of electromagnetic flowmeters, you can refer to: Installation Instructions for Electromagnetic Flowmeters. We will not go into details here.

Mass Flow Meter Installation

Step 1: Choose the Right Location

Before installing a mass flow meter, it is crucial to select an appropriate location in the piping system. Follow these guidelines:

- Straight Pipe Runs. If strong pipeline vibration is unavoidable, it is recommended to use flexible pipes to isolate the pipeline system from the instrument sensor;

- Avoid Bends and Valves

- Orientation

- Access for Maintenance

Step 2: Install the Flow Meter

Once the location is determined, follow these steps for installation:

- Turn Off the System

- Pipe Alignment: Ensure that the flow meter’s inlet and outlet are connected properly to the pipeline without causing misalignment or stress on the meter.

- Sealing and Gaskets: Install the appropriate gaskets or seals to prevent leaks at the connection points. Make sure they are rated for the fluid type and pressure.

- Electronics Connection: For electronic mass flow meters (such as Coriolis meters), connect the wiring from the flow meter to the control system or monitoring equipment. Ensure that the electrical connections are secure and that grounding is provided to avoid electrical interference.

- Flow Direction: Verify that the flow direction arrow on the flow meter matches the actual flow direction of the fluid. Installing the meter in the wrong direction can lead to incorrect readings or damage to the device.

Step 3: Verify Calibration

a. Zero Calibration: Perform a zero calibration to ensure that the flow meter reads zero when no fluid is flowing.

b. Span Calibration: If applicable, perform span calibration by introducing known flow rates of the fluid and comparing the readings to the expected values.

c. Verify Accuracy: Check the accuracy of the flow meter by comparing it to a trusted reference meter or through known calibration standards.

Step 4: Test the System

After installation and calibration, test the system by gradually increasing the flow rate and monitoring the flow meter’s readings. Ensure that the mass flow meter provides stable and accurate readings under various flow conditions.

More Flow Measurement Solutions

- Liquid Mass Flow Meters And Its Significance

- Gas Mass Flow Meters: Applications, Benefits, And Top Manufacturers

- Types Of Mass Flow Meters And Different Measurement Techniques

- Bulk Flow Meter for Solids | Applications and Benefits

- A Comparative Analysis Of Vertical And Horizontal Flow Meters

- LPG Gas Flow Meters With Some Prominent Manufacturers And Suppliers

- Grease And Lube Flow Meters

- Frame Of Flow Meters: Stainless Steel And PTFE Flow Meters

- Sewer Flow Meters and Their Importance in Sewer Monitoring

In the world of flow measurement, two outstanding contenders stand out: Mass flow meter and Magnetic Flow Meters. Each type has its strengths and applications, making them suitable for different industrial needs.

Sino-Inst is a popular hub of magnetic flow meters. Among different flow meter solutions, 30% are magnetic flow meters. Sino-Inst’s mass flow meters have high measurement accuracy. They include both Coriolis mass flow meters and thermal mass flow meters.

If you need to purchase a flow meter or have any related technical questions, please feel free to contact our sales engineers!

-1.jpg)