A liquid level float switch is a simple, easy-to-use, safe and reliable industrial process liquid level controller. It detects single or multiple extreme liquid level points, outputs switching signals, and provides liquid level control.

Liquid level float switches are specifically designed for liquid level detection, on-site signal transmission, and liquid level alarms in various small and medium-sized atmospheric and pressurized liquid storage tanks. They are suitable for hazardous locations involving sanitary, toxic, and corrosive media.

Benefits of Liquid Level Float Switches

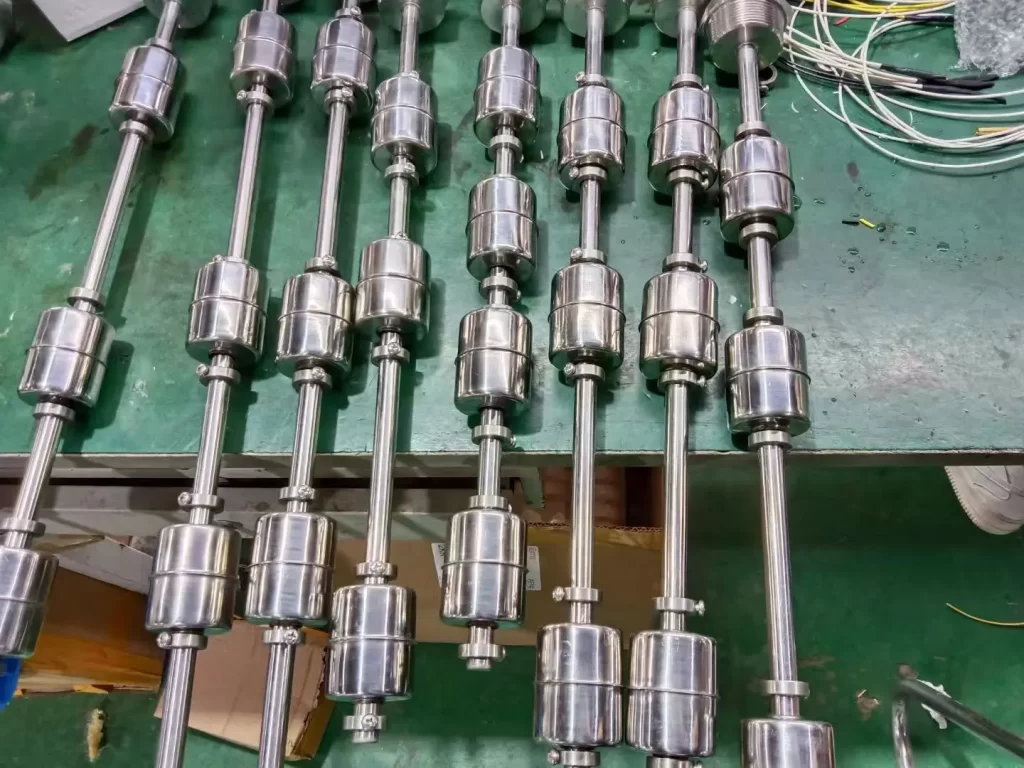

Featured Liquid Level Float Switches

Sino-Inst mainly supplies single-point and multi-point float level switches. We can customize the material to include stainless steel, plastic, copper, etc.

What are Liquid Level Float Switches?

A float level switch is an automated liquid level control device based on magnetic force, primarily used to detect the liquid position in a container and trigger a switch signal. Its core components include a magnetic float, a non-magnetic tube, and a reed switch. The float’s rise and fall in response to the liquid level drives the magnet, triggering the reed switch contacts to open and close, achieving contactless liquid level control.

Types of Float Switches

- Stainless Steel Float Switch

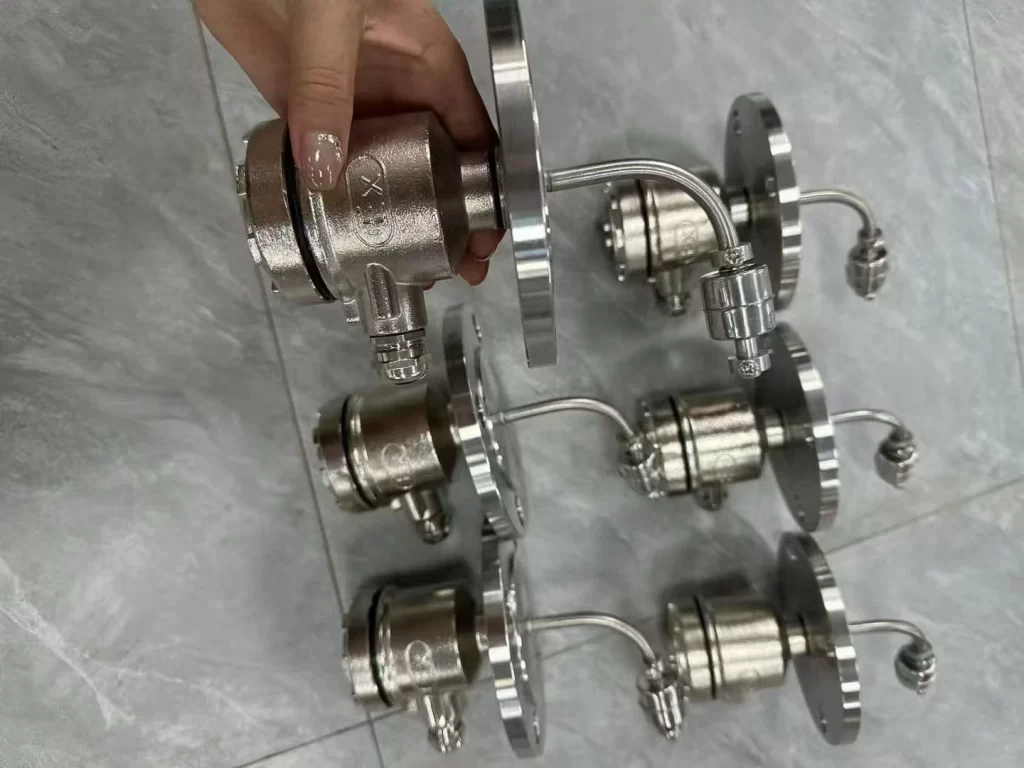

General-purpose stainless steel float level switches are available in both vertical and horizontal mounting configurations. They utilize a single 30VA or 100VA reed switch output and can reliably detect the level of relatively clean water, diluted chemicals, and light oils. Applicable media include deionized hot water and cooking oil. Stainless steel level sensors can be mounted vertically within the tank or horizontally on the tank wall for high or low level alarms. - Connecting Rod Float Level Switch

The connecting rod float level switch set provides reliable multi-point level detection for relatively clean water, diluted chemical solvents, and light oils, with a maximum range of 8′ (2.44 meters). It features 1-5 reed switch outputs and integrated wiring terminals within the integrated junction box. Made of stainless steel, the float level switch is suitable for level measurement in high-temperature or high-pressure process tanks. - Plastic Float Level Switch

Plastic float level switches are typically available in PP, PVDF, or PVC depending on their intended use. They utilize imported switching elements, are lightweight, and electrical parameters can be customized to meet customer requirements. Custom specifications are also available. Available in single-point or multi-point configurations. - Cable Float Switch

A cable float switch uses the principles of gravity and buoyancy to adjust the liquid level in a barrel, tank, or well. It is suitable for use in applications with 50/60Hz AC operating temperatures and a rated voltage up to AC250V. It is widely used in water pools, oil, weak acid and weak alkali pools, barrels, troughs, cans and other containers in homes, factories and mines.

Liquid Level Float Switches: Structure and Operating Principle

Simply put, liquid level float switches typically consist of the following components:

- A hollow float with an enclosed magnet

- A guide tube for guiding the float

- An adjustment collar to limit the float’s movement on the guide tube

- An internal reed contact

Liquid level measurement technology relies on the buoyancy of the float. The float’s magnetic float rises or falls with the liquid level, actuating a reed switch chip located at a predetermined position within the sensor tube, generating a contact open/close signal.

One or more reed switches are installed within a sealed, non-magnetic tube. This tube then passes through one or more floats with internal ring magnets. The rise or fall of the liquid causes the float to move up and down, causing the reed switch within the non-magnetic tube to engage or disengage, generating a switch signal.

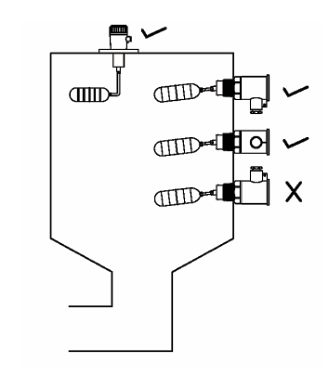

Horizontal vs. Vertical Mounting

Liquid Level Float Switches can be mounted horizontally or vertically.

Horizontal mounting is typically mounted on the side of a tank. Horizontally mounted float level switches are typically used for single-point liquid level monitoring.

Vertical mounting is typically mounted on the top of the tank. This type of switch can be customized for single-point or multi-point detection.

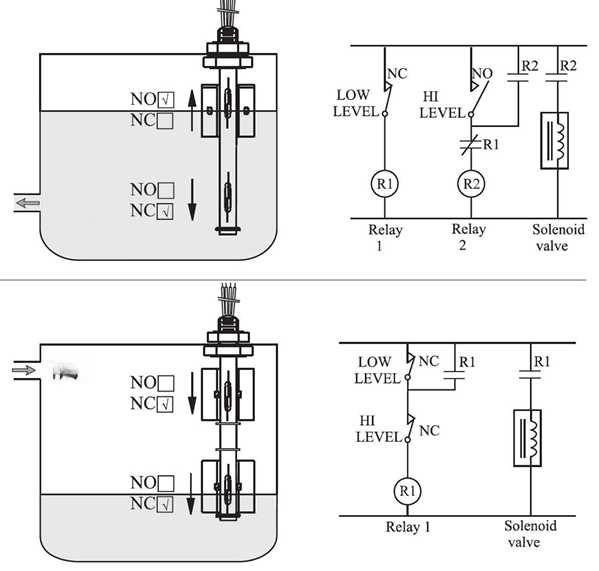

Normally Open vs. Normally Closed

The normally open and normally closed contacts of a float level switch differ significantly in their functions and applications. The following is a detailed description of the differences between these two types of contacts:

I. Definition and Operating Principle

Normally Open Contact (NO)

Definition: When not triggered (i.e., the liquid level has not reached the set point), the normally open contact is open.

Operating Principle: When the liquid level rises and pushes the float, the magnetic system inside the float triggers the reed switch inside the switch, closing the circuit. When the liquid level drops, the float drops, opening the reed switch, and the circuit returns to the open state.

Normally Closed Contact (NC)

Definition: When not triggered (i.e., the liquid level has not reached the set point), the normally closed contact is closed.

Operating Principle: When the liquid level rises and pushes the float, the magnetic system inside the float triggers the reed switch inside the switch, opening the circuit. When the liquid level drops, the float drops, closing the reed switch, and the circuit returns to the closed state.

II. Applications

Normally Open Contacts (NO)

Used in applications where a control action needs to be triggered when the liquid level rises. For example, a pump needs to be automatically shut down or an alarm system needs to be activated when the liquid level reaches or exceeds a set point. In these applications, a normally open switch ensures a timely signal when the liquid level rises, allowing appropriate control measures to be taken.

Normally Closed Contacts (NC)

Used in applications where a control action needs to be triggered when the liquid level falls. For example, a pump needs to be automatically started or an alarm needs to be activated when the liquid level falls below a set point. In these applications, a normally closed switch ensures a timely signal when the liquid level falls, allowing appropriate control measures to be taken.

III. How to Identify

Check the Product Manual: A straightforward method is to check the float level switch’s product manual. This will usually clearly indicate the contact type (normally open or normally closed).

Observe the wiring: A float level switch typically has three leads, one of which is a common lead. This common lead forms two sets of contacts with the other two leads: a pair of normally open contacts (NO) and a pair of normally closed contacts (NC). The contact type can be determined by observing the wiring.

Testing and Verification: In actual applications, the contact type of a float level switch can be tested by simulating liquid level changes. If the circuit closes when the liquid level rises, the contact is normally open. If the circuit remains closed, the contact is normally closed. Similarly, if the circuit opens when the liquid level falls, the contact is normally open. If the circuit remains closed, the contact is normally closed.

What is the difference between a limit switch and a float switch?

Broadly speaking, a float switch is a type of limit switch, as it functions by detecting the height of a liquid to output a control signal. Limit switches are generally used to detect the position of an object, while level switches focus on monitoring the height of a liquid.

Similarities: Float switches and traditional limit switches are both used for position detection. Both trigger switches based on changes in physical position, thereby controlling circuits or mechanical actions.

Differences: Float switches are specifically designed for detecting liquid media and involve more specific technologies and application environments. Limit switches, on the other hand, have a wider range of applications, including detecting the movement of solids and liquids.

What is the difference between a float level switch and a float level transmitter?

A float level transmitter is an instrument with remote transmission capabilities. It can also be equipped with a local digital display to show real-time liquid level values.

The principle is that several reed switches (this distance determines the resolution of the level gauge) and an equal number of resistors of equal value are installed at equal distances within the sensor guide rod. When the magnetic float floats to a certain position with the liquid surface, the reed switch at that position switches on the corresponding resistor (at least one to N resistors) representing that position. The resistance value at the output terminal represents the liquid level at that point. This resistance value is then converted by a transmitter into a standard 4-20mA current signal for output.

A float level switch is a simple level controller. It only outputs a switch signal. Because installation requires no complex circuitry, users only need to select the correct material. It can measure liquids, pressure, or temperature in any environment.

More Level Measurement Solutions

How to Choose the Right Float Switch?

To select the right liquid level float switch, consider the following parameters:

- Measured medium.

- Medium viscosity and density.

- Number of switch contacts/switch outputs.

- Location and function of each switch output.

- Probe length.

- Electrical connections (e.g., PVC cable outlet box).

- Process connection.

- Material (stainless steel, plastic, etc.).

- Ensure the float switch is dimensioned appropriately for the specific application.

Liquid Level Float Switches are simple, reliable liquid level controllers. They are widely used in water tanks, oil tanks, water towers, chemical storage tanks, food processing tanks, and other applications to monitor and control liquid levels and prevent overflows and dry runs.

Sino-Inst’s float level switches are available in a variety of materials and sizes. If you require liquid level measurement and control, please feel free to contact us.

-1.jpg)