Water pressure measurement includes pressure detection of water pipes, water containers or equipment. Water pressure measurements can be used to determine whether a pipe, container or equipment is leaking and whether it can withstand the pressure required for the design. By configuring a water pressure transmitter, connecting the water pressure signal to a recorder, PLC and other systems, or configuring a wireless signal, you can build a remote water pressure monitoring system.

Simply put, measuring water pressure mainly has the following three major functions:

- Ensure pressure stability;

- Leak monitoring;

- Monitoring of water levels;

Methods of water pressure Measurement

- Direct type: The measured liquid or gas is directly introduced into the sensor cavity or enters the sensor cavity through a pipeline.

- Indirect type: The fluid to be measured is introduced into the measuring tube outside the sensor through the conduit.

- Submersible type: fill the entire container with the liquid or gas to be measured. The pressure sensor is immersed in water.

- Isolated type: using isolation diaphragm. The pressure sensor does not come into contact with the medium being measured.

- Sealed type: The leakage of the liquid being measured is small.

Water Pressure Monitoring Device

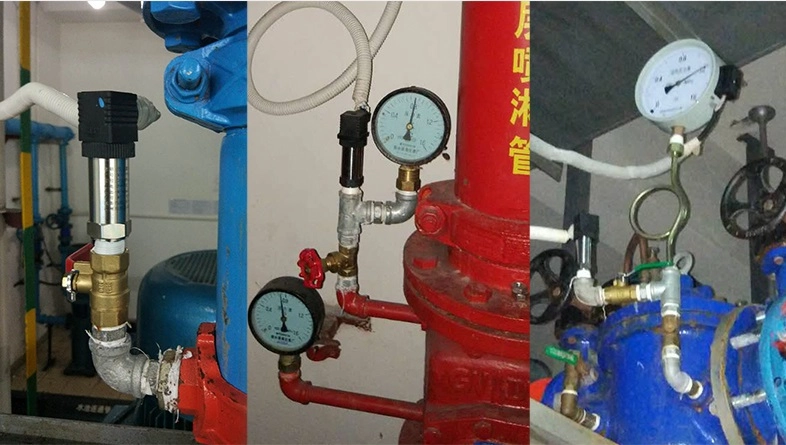

In both residential and industrial water pipelines, various devices are used to monitor water pressure. The most common is the pointer pressure gauge. We frequently see this type of pressure measuring device on pipelines, both at home and in factories. It requires no electricity and displays the real-time pressure with a pointer.

In some laboratories, U-tube manometers, bellows manometers, or Hall effect manometers are used to measure pressure.

Of course, in industry, we use more specialized and high-precision pressure measuring equipment, such as intelligent pressure transmitters and pressure controllers. These generally require a 24VDC power supply, can display pressure values in real time, and the pressure display unit can be adjusted, such as kPa, MPa, bar, mbar, etc. They also have signal output functions, such as switch signals, 4-20mA, 0-5V, 0-10V, RS485, HART, etc.

Industrial pressure transmitters and pressure controllers are not just simple water pressure measuring devices; they are crucial components for achieving industrial automation monitoring and control.

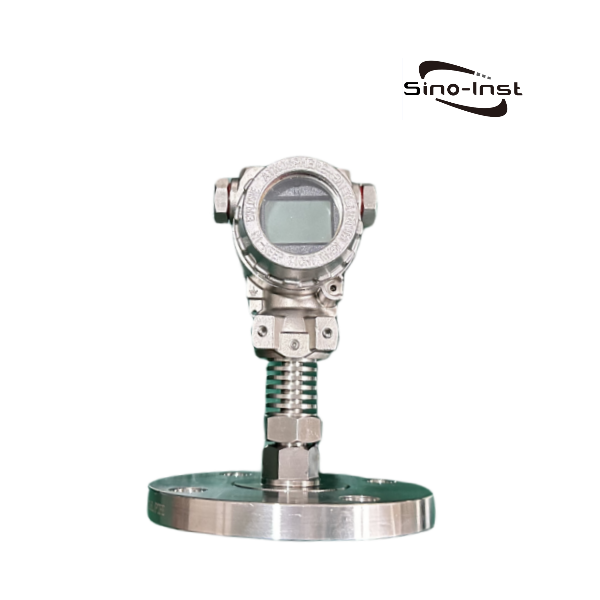

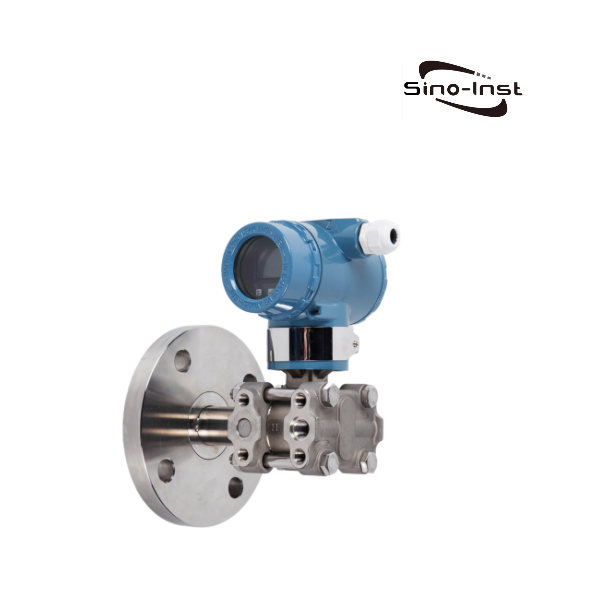

Featured digital pressure transmitter for water

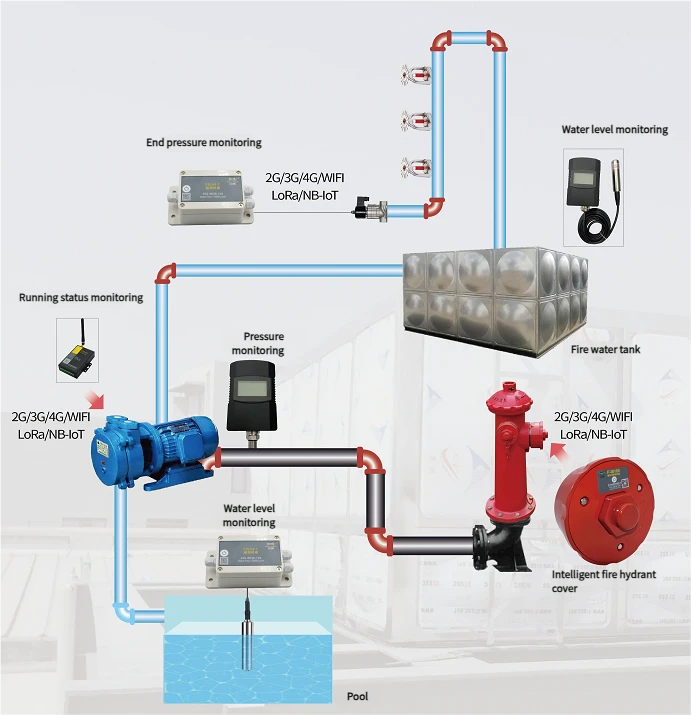

Construction of Water Pressure Monitoring System

If we only need to set up a water pressure monitoring system at a local factory, then we only need to configure: a pressure transmitter/pressure switch + a paperless recorder.

Install the pressure transmitter or pressure switch onto the water pipe or tank to be monitored, connect the power supply, and then output the signal. Then, configure a paperless recorder in the factory’s monitoring room. Connect the signal output from the pressure transmitter to the paperless recorder. We can then view the real-time pressure value and historical pressure data on the paperless recorder.

If multiple pressure points need to be monitored, a multi-channel paperless recorder can be selected. This way, all pressure data can be viewed on a single device.

If you need to monitor water pressure for a city or a region, then you will need to configure wireless communication and professional monitoring software. You can choose a pressure transmitter with wireless communication capabilities, such as LoRaWan, 4G, GPRS, etc. These wireless communication signals generally need to be compatible with the local network. Therefore, it is recommended that you configure it locally.

Water pressure monitoring applications

1. Industrial water treatment equipment

Medical water treatment equipment; electronic chemical ultrapure water treatment equipment; power plant unit cooling water treatment equipment; metallurgy, brewing, dairy and other water treatment equipment; water reuse, sewage treatment (domestic sewage, industrial sewage, food sewage, etc.), buildings Water supply and other engineering projects.

2. Drinking water treatment equipment (preferring pure water equipment)

Pure water equipment; mineral water equipment; fully automatic bottle (bucket) filling equipment (mechanical equipment); air shower and laboratory equipment. Reverse osmosis pure water equipment, boiler softened water equipment, high-purity water equipment for the electronics industry, hemodialysis water equipment, commercial reverse osmosis equipment, industrial reverse osmosis equipment, and water purification equipment.

3. Water supply equipment, complete sets of water supply (water supply) equipment:

a) Non-negative pressure variable frequency water supply equipment, non-negative pressure water supply equipment, variable frequency tower-less water supply equipment, automatic non-negative pressure water supply equipment, superimposed variable frequency water supply equipment, tap water supply equipment, secondary pressurized water supply equipment, non-negative pressure (overlapping pressure) water supply equipment, complete sets of air pressure water supply equipment, etc.;

b) Constant-pressure and variable-frequency water supply equipment: constant-pressure water supply equipment, variable-frequency constant-pressure water supply equipment, complete sets of fire-fighting constant-pressure water supply equipment, and industrial constant-pressure water supply equipment.

4. Auxiliary equipment for water treatment (pumps, cooling towers, tanks, etc.)

Water tank: stainless steel spherical water tank, complete set of water tank without negative pressure, fiberglass composite water tank, stainless steel water storage tank, thermal insulation water tank;

Pump: water pressure measurement and control of water pumps and water pipes, pressure measurement of mining water pumps. Install a pressure sensor at the outlet of the pump to detect pressure. Steam pump, suitable for medium and low pressure boiler water supply;

Towers and tanks: Commonly used ones have the word pressure in front of towers and tanks, and the pressure needs to be measured. The rest are used to measure the liquid level and water level in the tank. (The article “Tank Level Measurement with Pressure Transmitters” has a detailed introduction).

More Water Measurement Solutions

Choose Digital Water Pressure Switch for Better Control

Water Pressure Transducers – 2026 Guide With Product List

Water Level Pressure Transducers

A Comprehensive Analysis of Mechanical Water Flow Meters

Sea Water Resistant Pressure Sensors

What Is A Deep Well Water Level Sensor?

Ultrasonic Flow Meter for Water and Other Liquids

Water Pressure Measurement and Monitoring is essential in industrial practice. Water pressure sensors are widely used in various industrial dynamic environments, water conservancy and hydropower projects, transportation and construction equipment, production automatic control systems, aerospace technology, ship technology, transportation pipelines and other fields.

We at Sino-Inst supply various pressure transmitters that can be used to measure water pressure, detect water level, etc. And supports high temperature, high pressure and other customization. If you need to build a Water Pressure Monitoring system or have related technical questions, please feel free to contact our engineers!

-1.jpg)