Hydraulic pressure sensors are used to monitor the pressure in hydraulic systems. They ensure the safe operation of the system and provide information for controlling valves. The function of a hydraulic system is to increase force by changing pressure. It uses oil as the working medium. By utilizing the pressure of the oil, it controls the operation of hydraulic actuators through valves and other accessories.

Sino-Inst offers a variety of custom liquid pressure sensors. These include: custom mounting dimensions, custom signal outputs, custom high temperatures, and other extreme conditions.

What is a hydraulic pressure sensor?

A pressure sensor consists of a pressure-sensitive element and a signal processing unit. It is the most commonly used type of sensor in industrial practice. It is widely used in various industrial environments. These are involved in production automation, aerospace, military, petrochemical, and many other industries.

Hydraulic pressure sensors are a type of pressure sensor. They are specifically used to measure oil pressure in hydraulic systems. They are corrosion-resistant and heat-resistant. This ensures stable operation in complex working conditions. Ordinary pressure sensors are only suitable for measuring gas or liquid pressure. But they are not necessarily suitable for hydraulic systems.

Features

How does a hydraulic pressure sensor work?

Hydraulic pressure sensors sense pressure changes through sensitive elements. They convert mechanical pressure into an electrical output signal (such as a 4-20mA or RS-485 signal).

The working principle of a hydraulic pressure sensor is as follows: pressure acts directly on the sensor diaphragm. This causes the diaphragm to undergo a micro-displacement proportional to the medium pressure. This causes a change in the sensor’s resistance. An electronic circuit then detects this change. It converts and outputs a standard signal corresponding to this pressure.

Featured hydraulic pressure sensors

The following are our company’s special pressure sensors. They can be used for hydraulic system measurement.

SI-1150 Viscous Medium Hard Flat Diaphragm Pressure Sensor

The rigid flat diaphragm pressure sensor is designed and manufactured for harsh environments. Such as mud, coal slurry, concrete mixing, and oil field drilling. It is currently used in shield machines, industrial pumps, construction machinery, and other equipment.

The SI-1150 hard flat diaphragm pressure sensor is designed for viscous media. The measuring end features a solid, flush stainless steel diaphragm. This prevents hard sand from damaging the isolated flat diaphragm.

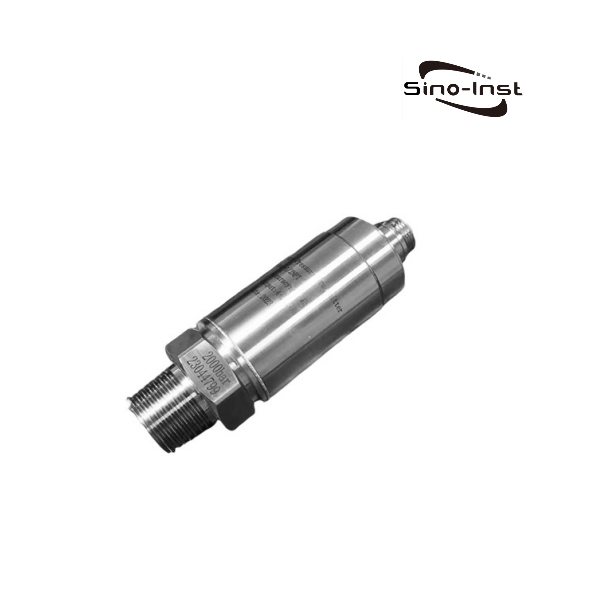

SI-702 Ultra-High Pressure Sensor

The SI-702 ultra-high pressure sensor is also known as a high-pressure pressure sensor or high-pressure pressure transmitter. This ultra-high-pressure sensor is made of rare metal alloy materials. It will not burst during ultra-high-pressure measurement and control. It is suitable for pressure measurement and control of large hydraulic equipment, etc.

It uses spherical or conical seals. This ensures the tightness of high-pressure systems. The SI-702 ultra-high-pressure sensor uses a stainless steel isolation diaphragm. Its integrated structure provides good impact resistance. It can adapt to harsh environments.

Features

- The SI-702 ultra-high pressure sensor offers excellent media compatibility.

- It is compact and highly accurate.

- The SI-702 ultra-high pressure sensor offers a variety of standard signal output options. This makes it easy to debug.

- It is lightning-proof and resistant to electromagnetic and radio frequency interference.

- It requires no filling fluid and is minimally affected by temperature.

SI-90 dynamic high frequency pressure sensor

A high-frequency pressure sensor, also known as a high-frequency dynamic pressure transmitter. It is a high-frequency analog pressure transmitter. It uses a flat-diaphragm stainless steel piezoresistive pressure sensor as the signal measurement element.

The sensor’s natural frequency can reach 1-2MHz. It can measure high-frequency pressure changes within a bandwidth range of 0-200KHz. The pressure measurement range is -100KPa~0~10Kpa…100MPa. The SI-90 dynamic high-frequency pressure sensor is a pressure-sensing device with high-speed measurement readout response. It is the preferred solution for dynamic pressure measurement.

Features

- Wide range of measurement media.

- Stable operation.

- Strong anti-interference capability.

- Small size and light weight.

- Complete range of types and high cost performance.

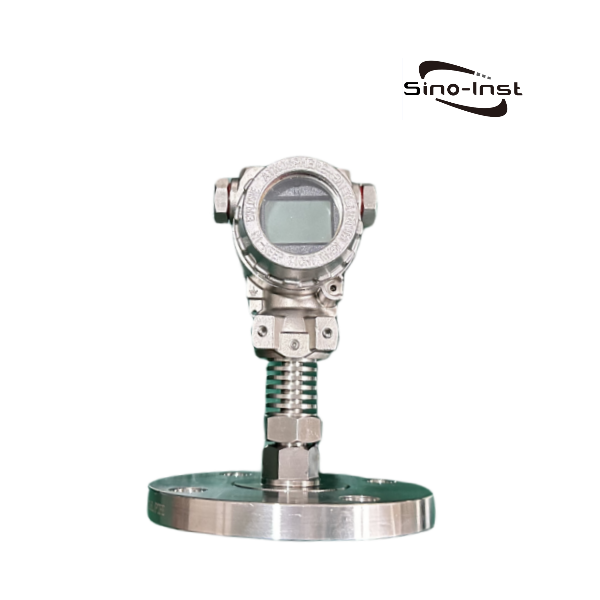

SI-703 Diaphragm Pressure Sensor

A diaphragm pressure sensor is also called a diaphragm pressure transmitter. The SI-703 diaphragm pressure sensor uses a sturdy flush diaphragm at the measuring end. Diaphragm pressure sensors are suitable for pressure measurement of high viscosity or granular fluids. This solves the problem of medium clogging in the pressure introduction hole.

The SI-703 diaphragm pressure sensor is mainly used to measure viscous media.For example, chemical coatings and paint testing systems.

Features

- Adopts a flat structure without pressure holes or cavities.

- High temperature resistance, with a maximum medium temperature of 300°C.

- Offers a wide range of pressures, including low, medium, and high.

- The pressure port utilizes a 316L flat diaphragm structure.

- The flat diaphragm design is suitable for a variety of viscous media.

Related technical specifications

| Range | -0.1 to 0 to 1 to 1000 (MPa) |

| Overall accuracy | 0.1%FS, 0.25%FS, 0.5%FS |

| Output signal | 4–20 mA (two-wire system), 0–5 V, 1–5 V, 0–10 V (three-wire system) |

| Supply voltage | 24 DCV (9–36 DCV) |

| Medium temperature | -20 to 85 to 150°C |

| Ambient temperature | Room temperature (-20 to 85°C) |

| Zero-point temperature drift | ≤±0.05%FS℃ |

| Compensation temperature | 0~70℃ |

| Insulation resistance | Greater than 2000MΩ (100VDC) |

| Sealing level | IP65 |

| Long-term stability performance | 0.1%FS/year |

What is the function of a hydraulic pressure sensor?

The function of a hydraulic pressure sensor is to monitor pressure changes in a hydraulic system in real time. It converts non-electrical signals into standard electrical signals for output. This ensures that the pressure within the system remains at the correct level or within the optimal range. They are mainly used in pneumatic and hydraulic systems.

In hydraulic systems, sensors provide real-time feedback on pressure data. They also help regulate the operating status of actuators. This ensures stable system operation. Some sensors monitor pressure changes and provide early warning of equipment wear. This reduces the failure rate.

Typical applications

- Industrial automation. They are used in the hydraulic systems of equipment such as punching machines and injection molding machines. They ensure the precision and safety of equipment operation.

- Automotive industry. Hydraulic pressure sensors can monitor the engine hydraulic system. And improve vehicle performance and safety.

- Aerospace. They ensure the stability and safety of aircraft hydraulic systems.

Advantages and limitations of hydraulic pressure sensors

Advantages

- High-precision measurement. Some models of hydraulic pressure sensors can achieve an accuracy of 0.1 grade. They can stably monitor pressure changes.

- High durability. Hydraulic pressure sensors are made of stainless steel and designed with an IP68 protection rating. They are suitable for extreme conditions such as high temperatures and high pressures.

- Fast response. Piezoelectric sensors have a fast response speed. They are suitable for dynamic pressure monitoring.

- Suitable for multiple scenarios. They are used in industrial automation, automotive braking systems, aerospace, and other fields.

Limitations

- Temperature sensitivity. Zero drift or full-scale error may occur in high-temperature environments.

- Overload risk. Severe pressure shocks may cause diaphragm rupture or internal circuit damage.

- Cost considerations. High-precision models are more expensive. Select the appropriate range and pressure resistance based on actual working conditions.

FAQ

More Pressure Measurement Solutions

The above are our hydraulic pressure sensors for industrial applications. They can measure pressure in a variety of liquids and in specialized environments. We also offer a variety of sensors for hydraulic systems.

Sino-inst offers over 50 types of pressure transmitters. These include single-crystal silicon pressure transmitters, capacitive pressure transmitters, and ceramic pressure transmitters. They are widely used in industries such as paper and pulp, food and beverage, and petroleum and chemical industries.

If you need to purchase a hydraulic pressure sensor or have any technical questions, please feel free to contact our sales engineers!

-1.jpg)