Explore flow measurement devices. Compare DP, magnetic, and other flow meters to select the right industrial sensor for your application.

Flow measurement devices are used to measure the flow rate of fluids in pipes or open channels. Common types include electromagnetic flow meters, ultrasonic flow meters, and turbine flow meters.

In my experience working with industrial systems, accurate data is the backbone of efficiency. Before diving into specific hardware, we have to understand the physics that dictate how fluid flow measurement devices actually work. It isn’t just about sticking a sensor in a pipe; it is about understanding the relationship between the fluid and the forces acting upon it.

Volumetric vs. Mass Flow: What Are You Counting?

The most fundamental decision I make when designing a system is choosing between volume and mass. This distinction impacts your flow meter accuracy significantly.

- Volumetric Flow: This measures the space the fluid occupies (e.g., gallons per minute or CFM for air). It is straightforward but can be tricky because volume changes if temperature or pressure shifts.

- Mass Flow Measurement: This counts the actual amount of matter (molecules) passing through (e.g., pounds per hour). For high-value liquid flow measurement devices, mass is king because it remains constant regardless of environmental changes.

The Role of Velocity and Pressure

Most types of flow measurement devices don’t measure flow directly; they infer it. We usually rely on two main variables:

- Velocity: We measure how fast the fluid moves past a point and multiply that by the pipe’s cross-sectional area.

- Pressure: Using Bernoulli’s principle, we create a restriction in the pipe. The pressure drop across that restriction tells us the flow rate.

Read more about: Pipe Flow vs Pressure – Relationship & Calculate Tools

Fluid Conditions

When planning measurements, water, oil, and natural gas cannot be treated the same. The “characteristics” of the fluid determine which type of fluid measurement equipment will function and operate correctly.

- Fluid Type: Whether you need air flow measurement equipment or sensors for abrasive slurries, the fluid composition (clean, dirty, or multiphase) dictates the technology we deploy.

- Viscosity: Is the fluid thick like syrup or thin like water? High viscosity creates resistance, which can interfere with the measurement of mechanical flow meters.

- Conductivity: This is crucial for electromagnetic flow meters. If the liquid is not conductive, these flow meters will not work.

- Measurement Scenario: Is it flow in a rigid pipe, flexible hose, partially filled pipe, open channel, or river?

Main Types of Flow Measurement Devices

We classify fluid flow measurement devices based on the physical principle they use to calculate flow. Here is a breakdown of the primary technologies we deal with daily.

Differential Pressure (DP) Flow Meters

These are the industry workhorses. DP meters measure the pressure drop caused by an obstruction in the pipe. The greater the flow, the higher the pressure drop. Common elements include:

- Orifice Plates: Simple, low-cost metal plates with a hole.

- Venturi Tubes: Tapered tubes that offer better pressure recovery.

- Nozzles: Designed for high-velocity steam or water flow.

- Bar-type throttling devices: Insertion installation, better suited for large-diameter pipelines.

Positive Displacement (PD) Flow Meters

If you need high precision for viscous liquids, positive displacement meters are often the answer. Think of these as a bucket system; they trap a fixed volume of fluid and count how many times the “bucket” fills and empties.

- Mechanics: Uses oval gears or rotary pistons.

- Best for: Viscous liquid flow measurement devices (like honey or oil) where other meters struggle.

Turbine Flow Meters

These rely on a spinning rotor inside the pipe. The flowing fluid hits the turbine blades, causing them to spin. The speed of the rotor is directly proportional to the fluid velocity. Turbine Flow Meters are excellent for clean, low-viscosity fluids but can suffer from wear if the fluid is dirty.

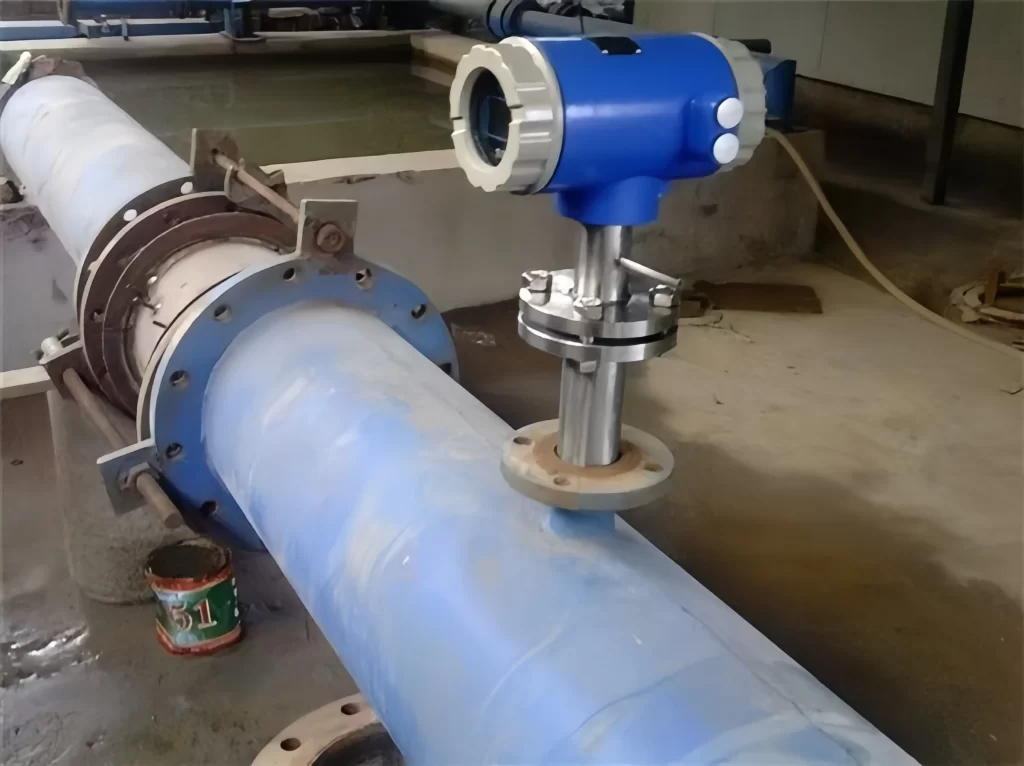

Electromagnetic (Mag) Flow Meters

Mag meters utilize Faraday’s Law of Electromagnetic Induction. As a conductive fluid flows through a magnetic field, it generates a voltage proportional to the velocity.

- No Moving Parts: Zero maintenance regarding mechanical wear.

- Requirement: The fluid must be conductive (water-based). They won’t work on hydrocarbons.

Ultrasonic Flow Meters

These non-intrusive devices use sound waves to determine flow rate.

- Transit-Time: Measures the time difference between signals sent upstream vs. downstream. Best for clean liquids.

- Doppler: Bounces sound off particles or bubbles in the stream. Best for dirty slurries or aerated liquids.

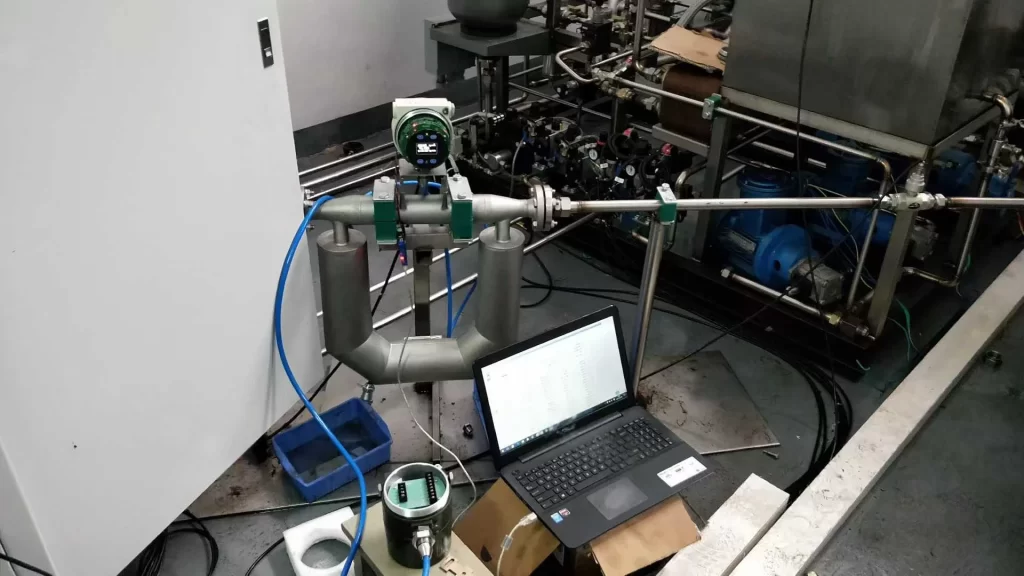

Coriolis Mass Flow Meters

For the highest accuracy, the Coriolis flow meter is the gold standard. It measures mass flow directly rather than volume. By vibrating a tube and measuring the twist caused by the flowing fluid, we get incredible precision regardless of pressure or viscosity changes. This is particularly vital when using extreme temperature flow meters in harsh processing environments.

Vortex Flow Meters

Based on the Von Karman effect, these meters place a “bluff body” (obstruction) in the stream. The fluid separates and forms alternating vortices (swirls) downstream. The frequency of these vortices indicates the flow rate. Vortex Flow Meters are rugged and great for steam, gas, and liquid.

Variable Area (Rotameter) Flow Meters

You have likely seen these simple, vertical tapered tubes with a float inside. As flow increases, the float rises. Variable Area (Rotameter) Flow Meters provide a simple, direct visual indication of flow rate without needing electricity.

Thermal Gas Mass Flow Meters

Thermal mass flow meters are based on the principle of thermal diffusion and accurately measure gases using the isothermal difference method. They measure the fluid’s mass flow rate by utilizing the temperature field change generated when a fluid flows through a pipe heated by an external heat source, or by using the relationship between the energy required to heat the fluid to a certain temperature rise and the fluid’s mass.

Open Channel Flow Measurement

Not all flow happens in a pipe. For rivers, canals, or wastewater effluent, we use open channel methods.

- Weirs and Flumes: Structures that shape the water flow.

- Level Sensing: Using ultrasonic or radar sensors to measure the height of the water as it passes the weir, converting that level to a flow rate.

Industry-Specific Applications for Flow Measurement Devices

Every industry has unique pain points, from strict regulations to hazardous conditions. We tailor our solutions to meet these distinct demands.

Here is how different sectors utilize flow meter applications:

Select the Right Flow Measurement Device

Choosing the correct hardware isn’t just about matching pipe sizes; it is about matching the technology to your specific process conditions. As a manufacturer, I see too many operations fail because they overlooked a single variable in the flow meter selection guide.

Here is the breakdown of what actually matters when sizing industrial flow sensors:

Assessing Fluid Properties

First, define exactly what is moving through the pipe. Is it a clean liquid, gas, or a slurry?

- Viscosity: Standard meters struggle with thick fluids. If you are monitoring heavy lubricants, you need specialized grease and lube flow meters designed to handle high viscosity without jamming.

- Conductivity: Mag meters only work if the fluid conducts electricity (like water). They generally will not work on pure hydrocarbons.

- Abrasiveness: Sand or grit in the line will destroy moving parts in a turbine meter quickly.

Determining Flow Range and Accuracy

Don’t just look at the maximum flow; look at the minimum. Every fluid flow measurement device has a “turndown ratio.” If your process runs low often, a meter with a wide range is essential. Also, define your accuracy needs honestly. Custody transfer requires 0.1% precision, but general process monitoring often only needs 1% to 2%.

Evaluating Installation and Environment

Where is the device going?

- Straight Pipe Runs: Most meters (like orifice or vortex) need straight piping—often 10 diameters upstream and 5 downstream—to smooth out turbulence for an accurate reading.

- Space Constraints: If you have zero straight pipe available, you might need a Coriolis or a specific type of Positive Displacement meter that is immune to flow profile issues.

- Environment: Is it outdoors or inside a hazardous chemical plant? Ensure the housing is rated for the environment (NEMA/IP ratings).

Integration with Control Systems

Flow data has to go somewhere. While the industry standard is still the analog 4-20mA loop, we are seeing a massive shift toward digital protocols.

HART/Modbus: Great for pulling extra variables like temperature or density alongside flow rate.

Wireless: Ideal for remote tank farms where running cable is too expensive.

By systematically checking these boxes, you ensure the liquid flow measurement devices you install will last longer and measure better.

FAQ

More Flow Measurement Solutions

Flow measurement equipment needs to be selected based on actual measurement parameters and requirements. Flow measurement and instrumentation technologies are constantly advancing. In the future, there will be more high-precision measurement technologies, wireless signal transmission technologies, and even energy-efficient measurement solutions.

Sino-Inst keeps pace with the times, providing users with the most stable and reliable Flow Measurement Devices. We support customization based on your measurement parameters and requirements. Please feel free to contact us anytime.

-1.jpg)