Gases are important raw materials in industrial production and laboratories. Such as oxygen, nitrogen, hydrogen, and natural gas. Gases are generally stored and transported in tanks and delivered through pipelines. Monitoring gas pressure during transportation and production helps ensure safe operations and reduce production costs.

How do you measure gas pressure? What devices are needed for gas pressure measurement? What precautions should be taken? Let’s take a look.

Gas Properties

Industrial gases are gases used in industrial production processes. They are compressed or liquefied and stored in bottles or cans. They are commonly used in various chemical reactions, combustion, oxidation, and reduction processes.

For example, oxygen is used in metal cutting, welding, and melting. Nitrogen is used in welding, sintering, and heat treatment under a protective atmosphere. Argon is used in processes such as shielded welding and metalworking.

Industrial gases can be divided into four categories based on their chemical properties:

- Highly toxic gases. These are extremely toxic and can cause poisoning or even death upon entry into the human body. Examples include chlorine and ammonia.

- Flammable gases. These are flammable and chemically explosive, and have a certain degree of toxicity. Examples include hydrogen and acetylene.

- Combustion-supporting gases. These gases support combustion but do not burn themselves, posing a risk of spreading a fire. Examples include oxygen.

- Non-flammable gases. These are asphyxiating, stable, and non-combustible. Examples include nitrogen, carbon dioxide, and argon.

Regardless of the type of gas, it’s necessary to measure its pressure during storage, transportation, and use.

How to measure gas pressure?

There are two common methods used in industry to monitor gas pressure in containers, tanks, or pipelines: mechanical and electronic. Both types of devices can be mounted directly on the tank or pipeline.

Mechanical Pressure Gauges Measure Gas Pressure

A pressure gauge uses an elastic sensor (such as a spring tube) to produce elastic deformation under pressure. The magnitude of this deformation is linearly related to the applied pressure. This pressure is amplified by a transmission mechanism, and a pointer on a graduated dial indicates the measured pressure.

Pressure gauges can be categorized by the type of elastic sensor: spring tube, bellows, diaphragm, and bellows.

The advantage of mechanical pressure gauges is that they do not require power. They offer immediate response and simple maintenance. Furthermore, the cost of the pressure gauge is low.

Electronic Pressure Transmitters Measure Gas Pressure

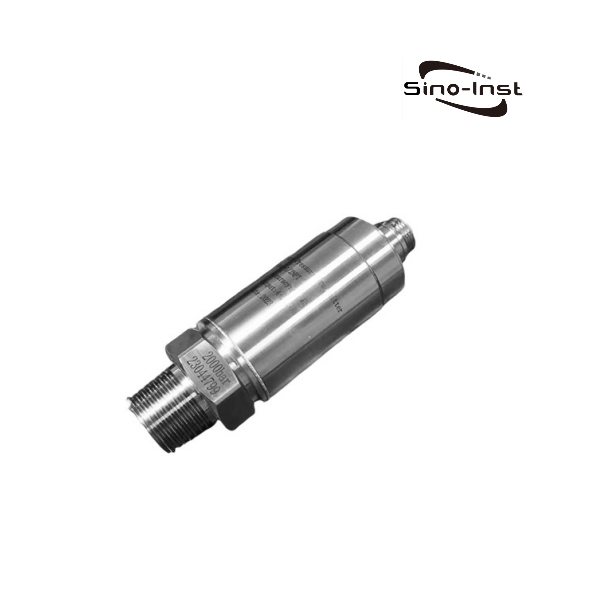

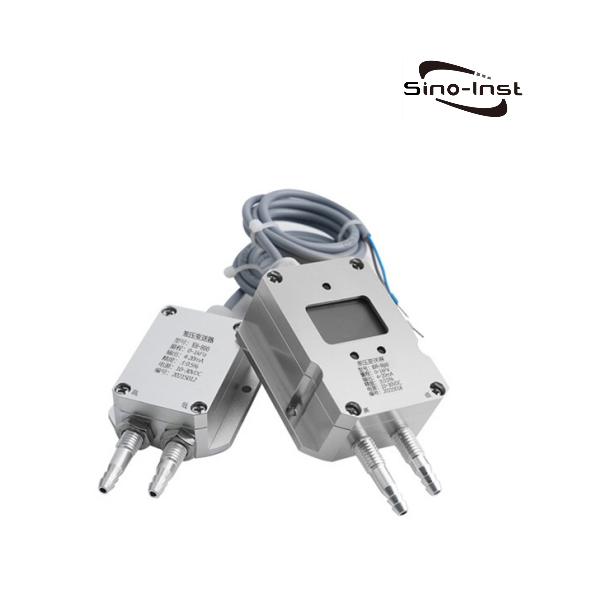

Electronic pressure transmitters can detect gas pressure in real time and output a corresponding standard electrical signal. They can be configured with a digital display or a switch alarm signal.

Electronic pressure transmitters require power to output a signal, typically 24VDC. Of course, they also offer many advantages, such as high measurement accuracy, a wide range of customization options, and temperature compensation.

Electronic pressure transmitters are even more diverse, so we won’t go into detail here. You can refer to: Industrial Pressure Transmitters: 7 Sensor Principles and 4 Main Types!

Gas Pressure Measurement Devices

Sino-Inst supplies over 50 types of gas pressure measurement equipment. Our pressure transmitters are customizable, especially for ultra-high pressure, high temperature, low temperature, and special mounting dimensions.

Specialty Gas Pressure Measurement

For clean, standard gases that are non-corrosive, you can simply select the appropriate pressure transmitter based on the pressure range and temperature. However, there are many specialty gases that require special consideration when selecting a transmitter.

More Pressure Measurement Solutions

Gas pressure measurement is crucial and essential. On one hand, it ensures safe storage and transportation; on the other, it helps control production costs and improve efficiency.

Sino-Inst has extensive experience in gas pressure measurement and offers customized solutions for a wide range of specific operating conditions.

-1.jpg)