Dual channel ultrasonic flow meter uses advanced ultrasonic flow/Heat measurement technology. Each channel can achieve measurement accuracy of ±1.0%. It can also be four-channel or multi-channel. The sound channels can be mutually redundant, greatly improving the accuracy and stability of the flow (heat) meter. It can effectively overcome the shortcomings of low accuracy and unstable flow (heat) caused by monophonic products that cannot adapt well to changes in the flow field.

Dual-channel ultrasonic flowmeters and multi-channel ultrasonic flowmeters can be used as measurement standards for quantitative control. Especially suitable for flow measurement of high viscosity oils, chemical products and ultrapure water. It can also be connected to two temperature sensors and used as a flow (heat) meter.

Features of Dual Channel Ultrasonic Flow Meters and Multi-Channels

- The measurement adopts dual-channel and multi-channel ultrasonic technology to ensure measurement accuracy and stability;

- Using a high-speed processor, the response speed reaches 0.1 seconds;

- Advanced digital signal processing technology, the measurement is not interfered by impurities such as iron filings and welding slag;

- Can be connected to different sensors to solve on-site multi-bubble application problems;

- Measurable liquids: most single-phase liquids. Less than 5% particles or bubbles;

- Pipe material: stainless steel, carbon steel, PVC, PPR, cement

- Flow measurement is not affected by fluid density, temperature, pressure, conductivity

- The required upstream and downstream straight pipe sections are short, the transducer has good anti-sticking properties and does not require regular cleaning.

Technical Parameters

| Applications | |

| Measurable liquids | Mostly single phase liquid. Less than 5% particles or bubbles. |

| Pipe material | Stainless steel, carbon steel, PVC, PPR, cement |

| Use ambient temperature | -40℃~ +60℃ |

| Measured fluid temperature | -20℃~ +150℃ |

| Measurable pipe diameter: | External clamp type: 20-50mm; 40-6000mm; plug-in type: DN65-6000 |

| Explosion-proof level | Explosionproof ExidII BT4; Intrinsically safe ExiaII BT4; |

| Performance indicators | |

| Flow rate range | Nominal accuracy flow rate range 0.1~7.0m/s |

| Measurement accuracy | ±1.0% |

| Sensitivity | 0.01m/s. |

| Measurement repeatability | ±0.2% |

| Protection level | IP65 |

| Power supply | External power supply: AC220V/DC18~27V; low power consumption: DC9~36V/built-in backup battery |

| Electrical Interface | External power supply: waterproof head 7×M20×1.5; low power consumption: waterproof head 4×M20×1.5 |

| LCD display | 128*64 dot matrix LCD screen |

| Keyboard input | 4 keys |

| Input and output signals | |

| Serial communication | RS485, MODBUS RTU protocol. |

| Flow output | Self-powered 4-20mA output/OCT |

Dual Channel Ultrasonic Flow Meter Working Principle

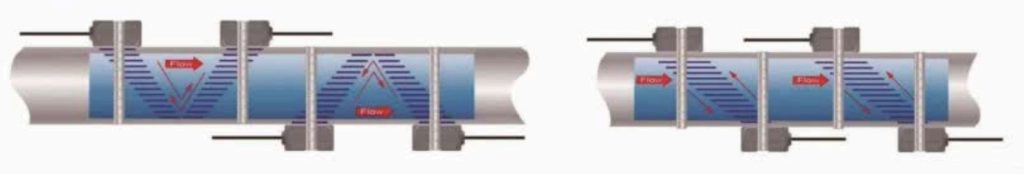

The transit-time ultrasonic flowmeter measures the flow rate by detecting and calculating the difference in the forward and reverse velocity of the ultrasonic pulse in the fluid.

When measuring, a pair of sensors are used to alternately transmit and receive ultrasonic waves in opposite directions. When the signal propagates in the downstream direction of the fluid, it is faster than in the counter-current direction. When the fluid is stationary, the time difference is zero.

Therefore, by measuring the propagation time of ultrasonic waves in downstream and countercurrent flow, the time difference Δ can be obtained. According to the relationship between Δt and flow velocity V, the average flow velocity of the fluid can be measured indirectly. The volume flow rate Q can be calculated based on the cross-sectional area of the pipe.

V=K△t Q=SV

formula:

K is a constant;

S is the internal cross-sectional area of the pipe.

Dual Channel Ultrasonic Flow Meter | Multi-Channels Applications

Dual-channel ultrasonic flowmeters are widely used in industrial flow measurement fields, especially in petrochemical, water treatment, food manufacturing and pharmaceutical industries.

It can measure the flow of various liquids. It has the advantages of high volume measurement accuracy, stable accuracy, and fast response speed.

At the same time, the dual-channel ultrasonic flowmeter can also achieve non-contact measurement. There is no need to install any probes or sensors in the pipeline. It can effectively avoid pipeline clogging or affecting the flow of liquid.

- Water, sewage, sea water

- Water supply and drainage

- Power plants (nuclear power, thermal power and hydraulic power)

- Heat, heating, heating

- Metallurgy and mining

- Petroleum and chemical industry

- Food and medicine

- Hull manufacturing and maintenance industry

- Energy saving monitoring and water saving management

- Paper and pulp industry

- Leak detection

- Traffic inspection, traffic tracking and collection

- Heat measurement, heat balance

14.Flow, thermal management, monitoring network system

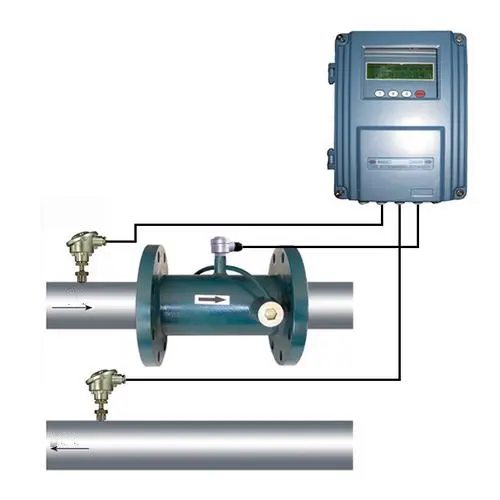

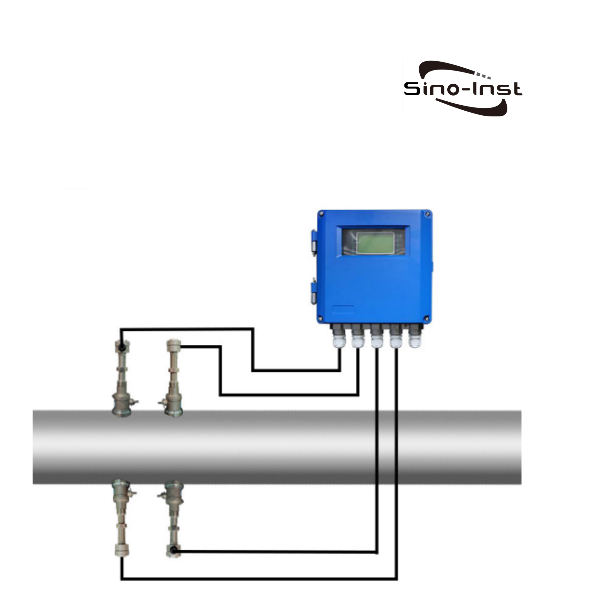

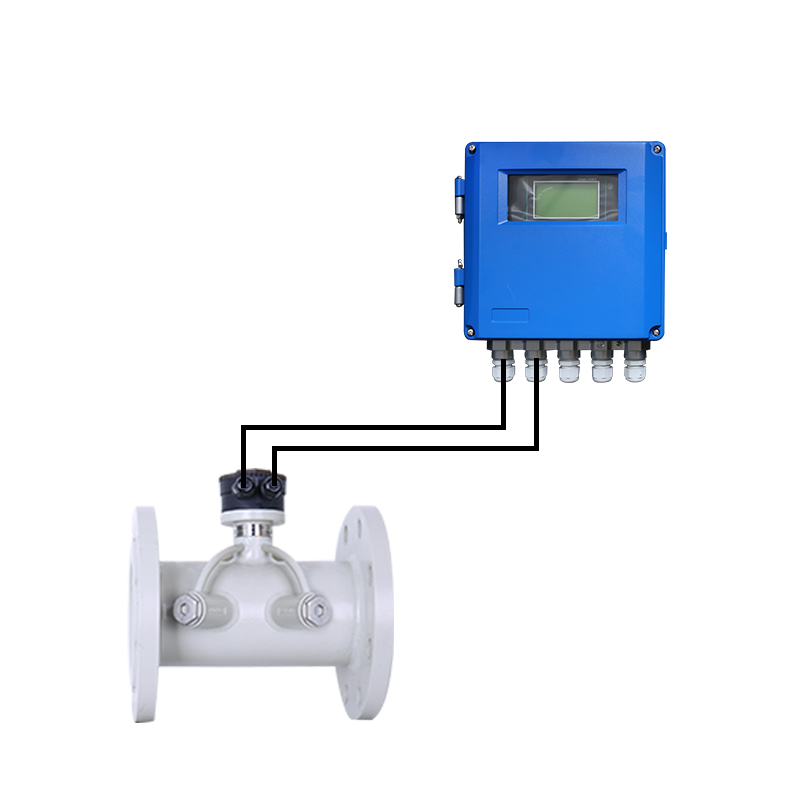

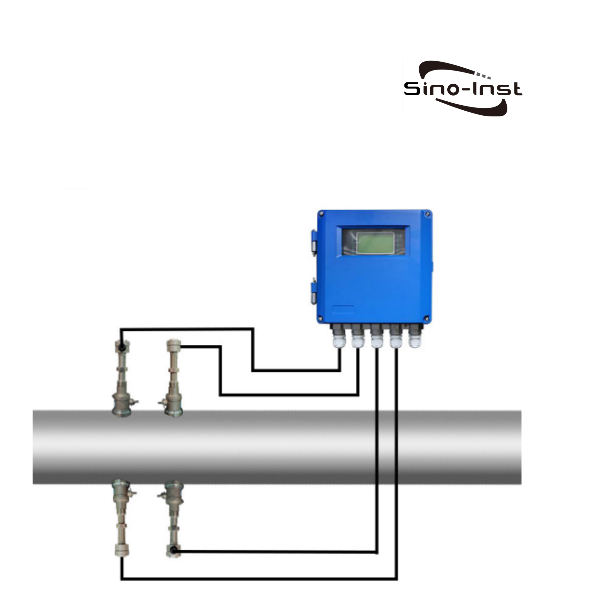

Dual Channel Ultrasonic Flow Meters sensor types and installation

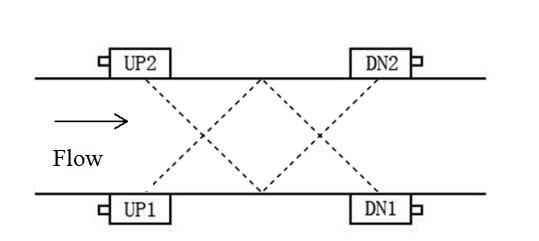

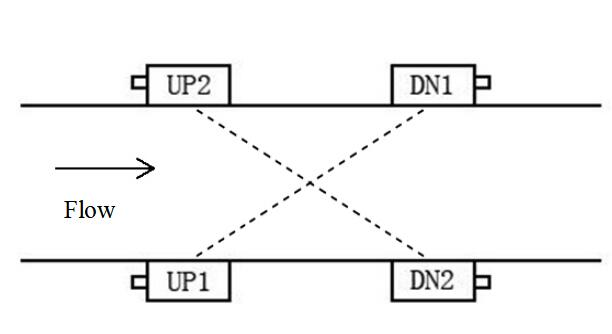

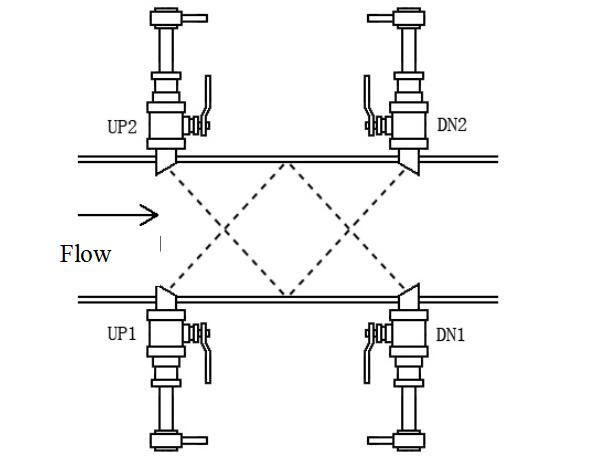

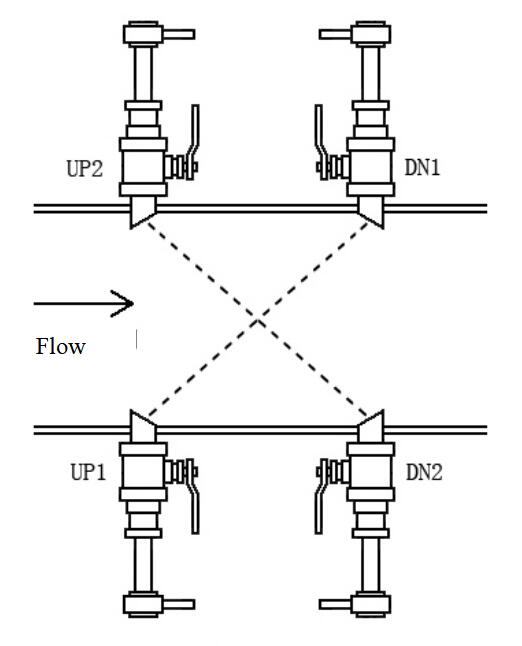

Dual Channel Ultrasonic Flow Meters sensors are divided into: external clamp type, insertion type and pipe segment type. Set the sensor installation method according to different application needs.

Generally speaking, it is recommended to use the Z-type installation method for external clip-on or plug-in types. It is not recommended to use the V method for installation.

If it is a mono-channel product, you only need to install the UP1/DN1 pair of sensors in the example in the picture. If it is a three-channel or four-channel product, add UP3/DN3 and UP4/DN4 sensors in the vertical direction accordingly.

More Flow Measurement Solutions

- Hydrogen Flow Meters for Mass and Volume Flow

- Beverage Flow Meters for Flow Monitoring and Quantitative Filling

- Industrial Digital Helium Flow Meters | Mass-Volume Flow

- Liquid and Gas NH3 Ammonia Flow Meters

- Magnetic Flow Meter Lining Material and Electrode Selection Guide

- Flowmeter Calibration & Recalibration

- Ultrasonic Flow Meter Technology

- Thermal Mass Flow Meter Technology

- Coriolis Mass Flow Meter Technology

- Differential Pressure Flow Meter Technology

- Vortex Flowmeter Technology

- Turbine Flowmeter Technology

- Magnetic Flowmeter Technology

Dual Channel Ultrasonic Flow Meters and multi-channel flow meters supplied by Sino-Inst use high-speed ARM core processors. Its response speed is less than 0.1 seconds. More than 10 times faster than conventional flow meters.

Dual Channel Ultrasonic Flow Meters can be used as measurement standards for quantitative control. Especially suitable for flow measurement of high viscosity oils, chemical products and ultrapure water. It can also be connected to two temperature sensors and used as a flow (heat) meter.

If you need to purchase Dual Channel Ultrasonic Flow Meters, or have related technical questions, please contact our engineers.

Dual Channel Ultrasonic Flow Meter|4 Channels|Multi-Channels

Dual channel ultrasonic flow meter uses advanced ultrasonic flow/Heat measurement technology. Each channel can achieve measurement accuracy of ±1.0%. It can also be four-channel or multi-channel. The sound channels can be mutually redundant, greatly improving the accuracy and stability of the flow (heat) meter. It can effectively overcome the shortcomings of low accuracy and unstable flow (heat) caused by monophonic products that cannot adapt well to changes in the flow field.

Product SKU: Dual Channel Ultrasonic Flow Meter | Four Channels | Multi-Channels

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 999

Price Valid Until: 2029-09-09

Product In-Stock: PreOrder

5

-1.jpg)