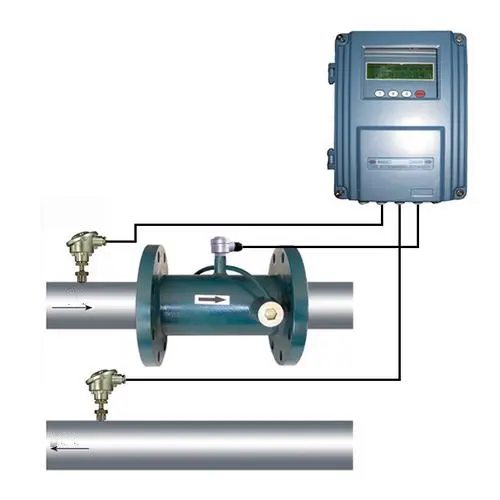

The doppler ultrasonic flow meter with insertion sensor is specially designed for measuring the flow of media such as liquids and slurries containing certain solid impurities and bubbles in closed pipes.

The Insertion sensor effectively solves the problems of external clamp-on measurement that cannot be effectively measured due to scaling on the inner wall of the pipeline, obsolete pipelines, non-sound-conducting materials in the pipeline, etc. and can obtain higher signal strength.

Features of Doppler Ultrasonic Flow Meter with Insertion Sensor

- Pipes with inner walls that are scaled, old, or made of non-sound-conducting materials can also be used.

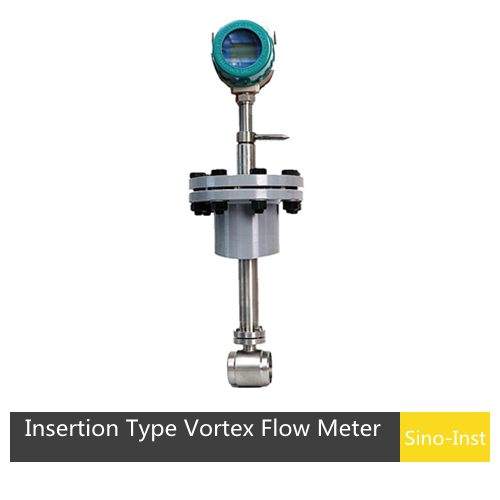

- Online installation. The Insertion sensor comes with a shut-off ball valve, so installation and maintenance do not require shutoff or pipe cutting, which is convenient and fast.

- Measurement accuracy 0.5-2%FS.

- Adaptive signal gain adjustment.

- Can resist interference from frequency converters.

- Easy to operate, just enter the inner diameter to achieve flow measurement.

- Instantaneous flow and accumulated flow pulse output and flow alarm output.

- 2-line 8-digit LCD can display instantaneous flow, accumulated flow, flow rate and other information.

Doppler Ultrasonic Flow Meter Technical Parameters

Transmitter

| Measurement principle | Ultrasonic doppler |

| Measurable flow rate range | 0.05 – 12 m/s, bidirectional measurement |

| Repeatability | 0.20% |

| Accuracy | 0.5% – 2.0% F.S. |

| Response time | 2-60 seconds, optional |

| Measurement period | 500ms |

| Pipe diameter range | 40-4000 mm |

| Measurable fluid | Reflectors (particles or bubbles) with content exceeding 100ppm, and particle size >100 microns |

| Power supply | AC: 85-265V DC: 24V/500mA |

| Installation method | Wall-mounted |

| Protection level | IP66 |

| operating temperature | -20℃ to +60℃ |

| Housing material | fiberglass |

| Display | 2-line 8-digit LCD, 8-digit instantaneous flow, cumulative flow (resettable) |

| Units of measurement | Volume/mass/speed: liters, cubic meters, kilograms, meters, gallons, etc.; flow time unit: seconds, minutes, hours, days; cumulative flow rate: E-2 ~ E+6 |

| Communication output | 4~20mA, totalizer pulse output, instantaneous flow alarm, error alarm and power interruption alarm |

| Press button | 6 buttons |

| Dimensions | 244*196*144mm |

| Weight | 2.4kg |

Sensor

| Protection level | Standard IP67, IP68 optional |

| Measurable fluid temperature | Standard sensor: -35℃~85℃ |

| High temperature sensor: -35℃~150℃ | |

| Testable pipeline | S type (40-4000 mm) |

| Sensor size | S standard sensor Φ58*199mm |

| Sensor material | Stainless steel |

| Cable length | Standard 10m, other lengths can be customized |

Doppler ultrasonic flow meter pros and cons

Advantages of Doppler ultrasonic flow meter

The main advantage of the Doppler ultrasonic flow meter is that it is suitable for rigid pipes such as steel and rigid plastic pipes. Liquids containing suspended solid particles or bubbles in tubes of various diameters and wall thicknesses can be measured.

It is mainly used in environmental testing of urban sewage treatment plants, drainage pumping stations, and flow measurement of urban drainage, industrial wastewater, domestic sewage, mud, pulp, oil-water mixture, etc. in mining, oil fields, metallurgy, chemical industry, oil refining, papermaking, food and other industries.

In addition, Doppler ultrasonic flow meter has the following advantages:

- Easy to install and disassemble

- Online installation

- No moving parts worn

- No process pollution

- Suitable for waste water or corrosive fluids

- No leakage

- Not affected by factors such as liquid temperature, viscosity, density or pressure

Disadvantages of Doppler Ultrasonic Flowmeter

The main disadvantage of Doppler ultrasonic flow meters is that the liquid being measured must contain particles, bubbles, or other types of solids or impurities to reflect ultrasonic signals. This means that ultrasonic flow meters cannot be used for pure water and very clean liquid measurements.

In addition, the measurement accuracy of ultrasonic flow meters is affected by particle size distribution and concentration. It is also affected by the possible relative velocities between the particles and the fluid. If there are not enough particles in the fluid, repeatability will decrease. If the flow velocity in the pipeline is too low, it will also increase the difficulty of measurement.

Doppler ultrasonic flow meter Applications

1. Liquid medium

Doppler flowmeters are excellent in flow measurement of liquid media. Its scope of application covers the measurement of many liquid media. For example:

Acid, alkali, hydrochloric acid, sulfuric acid and other chemical liquids

Crude oil, gasoline, fuel oil and other energy liquids

Cement slurry, lime slurry and other granular material slurries

2. Sewage medium

The nature of sewage media is complex, and traditional flow meters are difficult to meet its measurement needs. The Doppler flowmeter adopts a non-contact operation mode, which gives it certain advantages in measuring sewage media. The applicable sewage media for Doppler flowmeters include:

Sewage, wastewater and water treatment media of varying concentrations;

Thick sewage mainly composed of sludge, gravel, sediment, etc.;

Medium in special environments such as low temperature and high temperature sewage.

Doppler flowmeter is easy to operate, accurate and reliable in sewage medium measurement.

More Insertion Flow Meters

What is the Doppler effect?

The Doppler effect is a phenomenon caused by the movement of fluid between the transmitter and receiver of sound waves. The high-speed liquid flow will change the transmitted sound waves, causing a frequency shift at the receiving end, thereby producing the so-called Doppler effect.

How to deal with the Doppler effect?

The Doppler effect is measured using a Doppler flow meter. Flow meters have sensor adjustments for the Doppler effect to ensure accuracy.

Doppler flowmeter types vary based on application environment and measurement needs. It is important to carefully evaluate our application environment and measurement requirements to determine the correct measurement tool.

Traditional Doppler flow meters are suitable for measuring large pipes and pipelines. Portable Doppler flow meters are suitable for measuring flow in small equipment and difficult to reach locations. It is very important to understand and deal with the Doppler effect to ensure the accuracy and stability of the flow meter.

More Flow Measurement Solutions

- Flowmeter Calibration & Recalibration

- Ultrasonic Flow Meter Technology

- Thermal Mass Flow Meter Technology

- Coriolis Mass Flow Meter Technology

- Differential Pressure Flow Meter Technology

- Vortex Flowmeter Technology

- Turbine Flowmeter Technology

- Magnetic Flowmeter Technology

Doppler ultrasonic flow meters emit a beam of sound waves from the instrument. And this sound wave will echo. During the echo process, the Doppler effect occurs. That will cause the frequency of the echo signal to change. By measuring this frequency change, parameters such as the flow rate and flow rate of the medium can be accurately calculated.

Doppler Ultrasonic Flow Meter uses the Doppler effect principle. It can automatically compensate for the influence of fluid viscosity to ensure measurement accuracy. The Doppler Ultrasonic Flow Meter’s sensor also has no effect on liquid media.

If you need to purchase Doppler Ultrasonic Flow Meter, or have related technical questions, please contact our engineers!

Doppler Ultrasonic Flow Meter with Insertion Sensor

The doppler ultrasonic flow meter with insertion sensor is specially designed for measuring the flow of media such as liquids and slurries containing certain solid impurities and bubbles in closed pipes.

Product SKU: Doppler Ultrasonic Flow Meter with Insertion Sensor

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 999

Price Valid Until: 2029-09-09

Product In-Stock: PreOrder

5

-1.jpg)