What is a diaphragm seal?

A diaphragm seal is a sealing device used to prevent fluid leakage, usually composed of a diaphragm, bolts, gaskets and other components. Its main function is to isolate two different media to prevent them from mixing or leaking.

The working principle of a diaphragm seal is to use the elasticity of the diaphragm to achieve sealing. When the medium pressure acts on the diaphragm, the diaphragm is deformed by force. Thus, the two media are isolated and prevented from crossing each other.

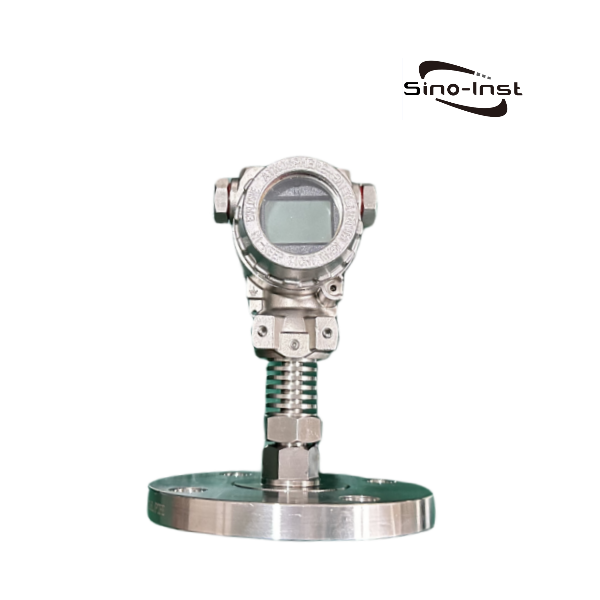

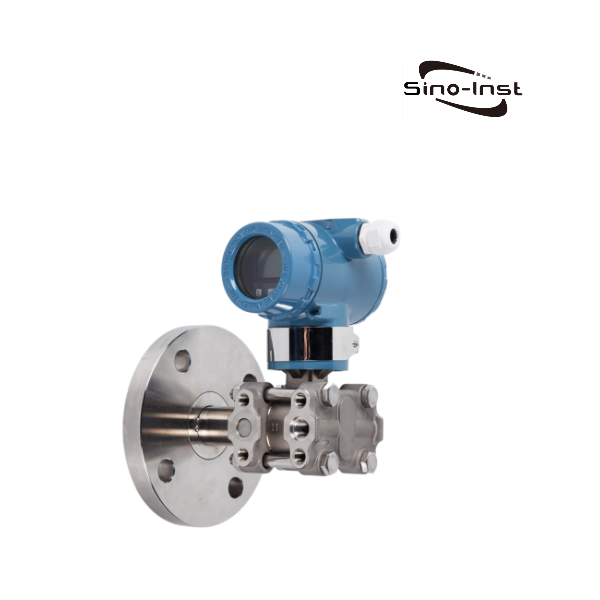

Diaphragm seal systems are usually installed with pressure gauges, pressure switches, and pressure transmitters.

These seals are very important because they help isolate the pressure sensor from the contents that may be toxic, reactive or irritating chemicals. In this article, we will discuss the details of diaphragm seals and their various types.

Structural composition of diaphragm seals

Generally speaking, diaphragm seals include diaphragms, middle bolts, middle gaskets, plug plates, anchor bolts, anchor gaskets, etc.

Among them, the diaphragm is the key component of the isolation medium, and is usually made of rubber, fluoroplastics, polytetrafluoroethylene and other materials. To ensure its corrosion resistance, high temperature resistance and pressure resistance.

Types of Diaphragm Seals System

Diaphragm seals are usually made of 316 stainless steel, Teflon, Hastelloy, Inconel, etc. The requirements of diaphragm seals vary for each industrial application. They can be customized according to your requirements. Here are some common types of diaphragm seals:

Benefits of using diaphragm seals on pressure measurement

It is worth investing in diaphragm seals, which can effectively control costs. And ensure the safety of users. In addition to the obvious advantage of isolating the instrument from the contents. Here are some other advantages of diaphragm seals:

- Helps prevent liquid clogging and crystallization;

- Eliminates the risk of corrosion or any reaction of fluids with these mainly metal devices;

- Enables the instrument to operate normally in a wide temperature range and in a variety of toxic liquids and semi-solids;

- Helps extend the service life of closed instruments;

- Available in all standard sizes and nominal diameters;

- All wetted parts can be made of special materials selected by the user;

- Rugged and durable, fully welded design;

Diaphragm seal pressure transmitters are suitable for the following working conditions:

- The high temperature medium needs to be isolated from the transmitter.

- The measured medium has a corrosive effect on the sensitive elements of the transmitter.

- Suspended liquid or high viscosity medium.

- The measured medium solidifies or crystallizes due to changes in ambient or process temperature.

- Replacing the measured medium requires strict purification of the measuring head.

- The measuring head must be kept clean and hygienic.

- Sealed pressure vessel level measurement.

More Featured Pressure Transmitters and Solution

- More Powerful Pressure Transmitter with Diaphragm Seal and Capillary

- Vacuum Pressure Sensors | Vacuum-Negative Pressure Measurement

- Industrial Pressure Sensors for High Pressure Measurement

- Capacitive Pressure Transmitter | Manufacturer’s Guide & Product List

- Industrial Water Pressure Measurement and Monitoring

- Tank Level Measurement with Pressure Transmitters/DP Transmitters

- High Temperature Pressure Transducers|800℃~1200℃

- Fluid Pressure Sensors for Industrial Liquids Pressure Measurement

- Industrial HART Pressure Transmitters and DP Transmitters

Diaphragm seals protect measuring instruments from aggressive, viscous, crystallizing, corrosive, highly viscous, environmentally harmful or toxic media. Diaphragms made of appropriate materials isolate the measuring instrument from the measured medium.

At Sino-Inst, we can provide diaphragm seals in different designs and materials to meet all application requirements. When choosing a diaphragm seal, you need to pay attention to two important criteria: one is the type of process connection (flange, thread and sterile connection); the other is the basic manufacturing method. If you have any technical questions, please feel free to contact our sales engineers!

-1.jpg)