Selecting the appropriate pressure reference—gauge or absolute—is crucial for accurate pressure measurements. An incorrect choice may result in errors of around 1 bar, especially for low range devices.

In this article, we aim to clarify the differences between gauge and absolute pressure measurements, providing a clear understanding of their definitions and applications. By exploring these distinctions, you’ll be better equipped to choose the right pressure range for your instrumentation, ensuring accurate and reliable results.

Gauge Pressure

Definition and explanation of gauge pressure

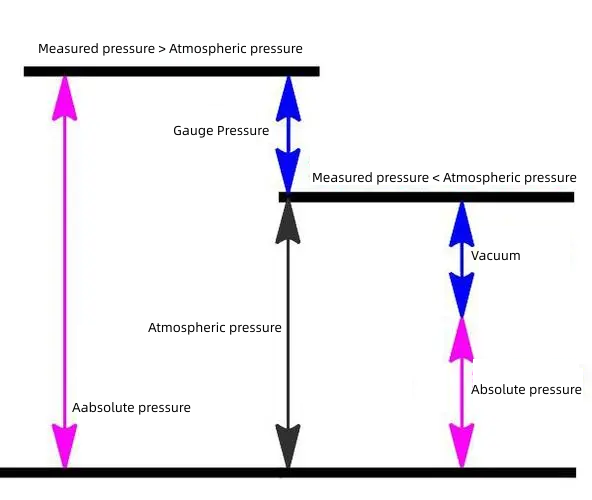

Gauge pressure is a commonly used pressure measurement that takes atmospheric pressure as its reference point. In other words, it represents the difference between the measured pressure and the local atmospheric pressure. This method of measurement allows us to focus on the pressure exerted by a specific system or process, excluding the influence of the surrounding atmosphere.

Gauge pressures can be positive or negative. Positive gauge pressures indicate that the measured pressure is higher than atmospheric pressure, while negative gauge pressures, also known as vacuum pressures, signify that the measured pressure is lower than atmospheric pressure.

Units of gauge pressure

Gauge pressure can be expressed in various units, depending on the application and preference. Some of the most common units used for gauge pressure include:

- Pascals (Pa): The SI unit for pressure, where one Pascal equals the pressure of one newton per square meter (1 Pa = 1 N/m²). This unit is widely used in scientific and engineering contexts.

- Pounds per square inch (psi): A widely used unit in the United States and the UK, particularly in the automotive and industrial sectors. One psi equals the pressure exerted by one pound-force per square inch of surface area (1 psi = 6894.757 Pa).

Other units for measuring gauge pressure include millimeters of mercury (mmHg), inches of water column (inH2O), and bars. When expressing gauge pressure, it’s important to indicate that the measurement is relative to atmospheric pressure. This can be done by adding a “g” to the unit abbreviation, such as psig for pounds per square inch gauge or barg for bars gauge.

absolute pressure

Definition and explanation of absolute pressure

Absolute pressure is a type of pressure measurement that uses vacuum, or a perfect absence of pressure, as its reference point. Unlike gauge pressure, which compares the measured pressure to atmospheric pressure, absolute pressure represents the true pressure value from absolute zero pressure.

The relationship between absolute pressure and gauge pressure can be expressed mathematically. To convert gauge pressure to absolute pressure, you simply add the local atmospheric pressure to the gauge pressure value:

Absolute Pressure = Gauge Pressure + Atmospheric Pressure

Conversely, to find gauge pressure from absolute pressure, subtract the local atmospheric pressure:

Gauge Pressure = Absolute Pressure – Atmospheric Pressure

Understanding the difference between these two types of pressure measurements is essential when selecting the appropriate pressure sensor for a specific application, as it ensures accurate and reliable results.

Units of absolute pressure

Absolute pressure can be expressed in various units, similar to gauge pressure. Some of the most common units used for absolute pressure include:

- Pascals (Pa): The SI unit for pressure, where one Pascal equals the pressure of one newton per square meter (1 Pa = 1 N/m²). Pascals are widely used in scientific and engineering contexts.

- Pounds per square inch absolute (psia): A common unit used in the United States and the UK, particularly in the automotive and industrial sectors. One psia equals the pressure exerted by one pound-force per square inch of surface area (1 psia = 6894.757 Pa), measured from an absolute vacuum.

Other units for measuring absolute pressure include atmospheres (atm), millimeters of mercury absolute (mmHg), and bars absolute. When expressing absolute pressure, it’s important to indicate that the measurement is relative to an absolute vacuum. This can be done by adding an “a” to the unit abbreviation, such as psia for pounds per square inch absolute or bara for bars absolute.

Differences Between Gauge and Absolute Pressure

The main differences between gauge and absolute pressure can be categorized into five key areas:

| Category | Gauge Pressure | Absolute Pressure |

|---|---|---|

| Reference Points | Atmospheric pressure | Vacuum (absolute zero pressure) |

| Applications & Industries | Pneumatic systems, hydraulic systems, HVAC, pressure vessels | Vacuum systems, meteorology, thermodynamics |

| Units of Measurement | Pascals (Pa), pounds per square inch gauge (psig), etc. | Pascals (Pa), pounds per square inch absolute (psia), etc. |

| Instruments | Bourdon tube pressure gauges, diaphragm pressure gauges, manometers | Barometers, vacuum gauges, absolute pressure transducers |

| Effects of Altitude & Temperature | Affected by atmospheric pressure changes due to altitude and temperature | Less sensitive to environmental factors, as it measures relative to a vacuum |

Relationship Between Gauge and Absolute Pressure

The relationship between gauge and absolute pressure is essential to understand for various applications and industries.

Here are the key aspects of this relationship:

Mathematical relationship:

There is a simple conversion formula between gauge and absolute pressure.

To convert gauge pressure to absolute pressure, add the local atmospheric pressure to the gauge pressure value:

Absolute Pressure = Gauge Pressure + Atmospheric Pressure.

Conversely, to find gauge pressure from absolute pressure, subtract the local atmospheric pressure:

Gauge Pressure = Absolute Pressure – Atmospheric Pressure.

Interdependence in real-world applications:

In many practical scenarios, both gauge and absolute pressure measurements are necessary to provide a complete understanding of system performance.

For example, in refrigeration systems, gauge pressure is used to measure the pressure in cooling lines. While absolute pressure is essential for understanding the performance of vacuum pumps and compressors.

How do you convert gauge pressure to absolute pressure?

Based on the above, we already know the relationship between absolute pressure and gauge pressure. Now, we can convert between the two.

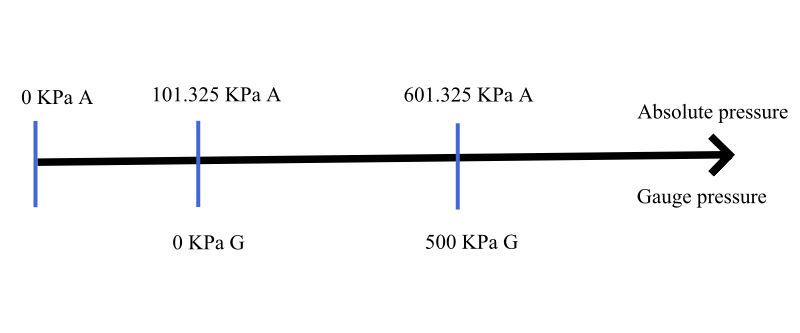

Referring to the figure below, if atmospheric pressure = 101.325 kPa and gauge pressure is 500 kPa, then:

Absolute pressure = 500 kPa + 101.325 kPa = 601.325 kPa

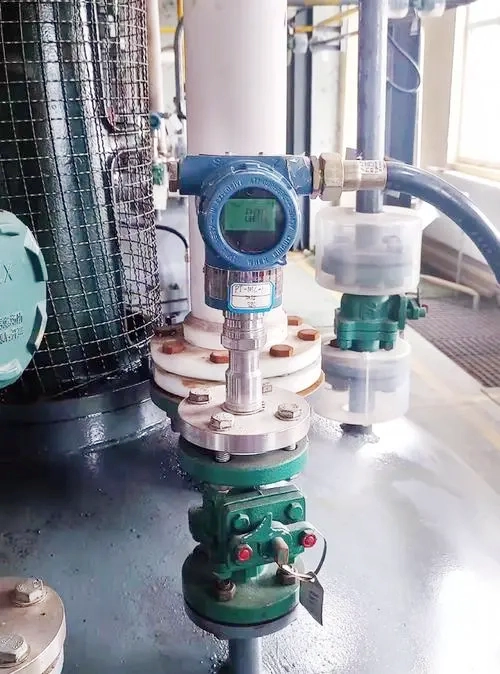

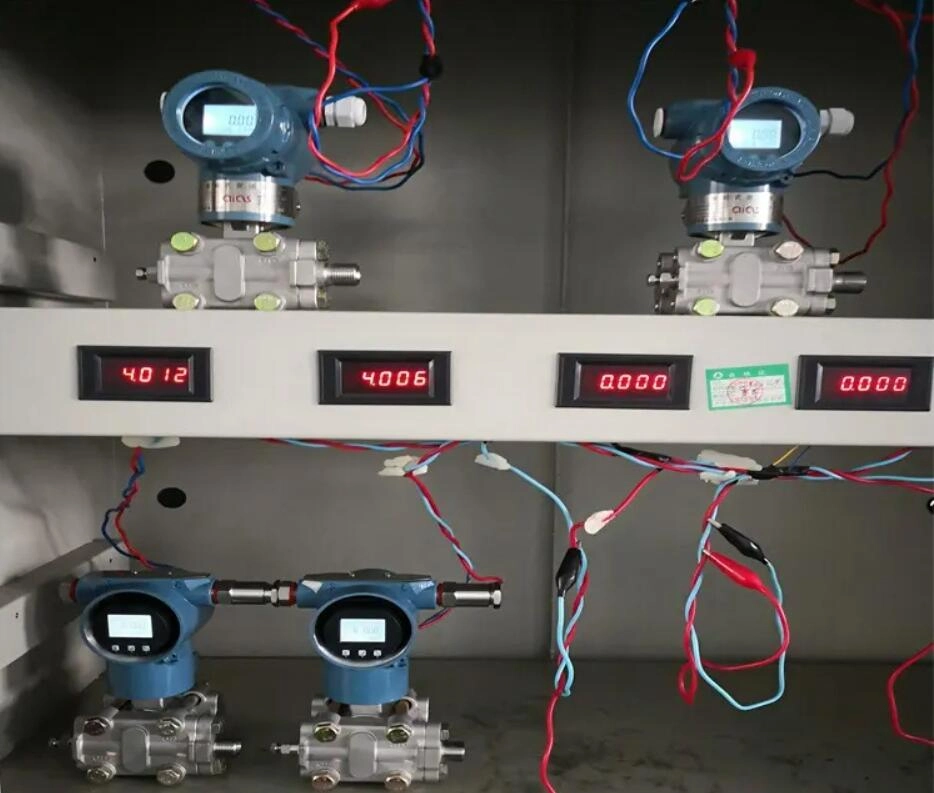

Featured AP and GP Pressure Transmitters

Both absolute and gauge pressures can be directly measured using a pressure transmitter. Of course, when ordering a pressure transmitter, be sure to specify the type of pressure you wish to measure.

When to Measure Absolute Pressure? When to Measure Gauge Pressure?

Choosing between gauge and absolute pressure measurements isn’t always simple, but some general guidelines can help.

If you need to measure or control a pressure affected by atmospheric pressure changes. Such as liquid levels in an open tank or the output pressure of an air compressor, a vented gauge pressure instrument is typically used. In these cases, the pressure reading must account for the atmospheric pressure component.

On the other hand, when measuring pressures unaffected by atmospheric changes. Like leak testing a completely sealed and rigid container, an absolute pressure sensor is more suitable. Using a gauge pressure sensor in this situation could lead to inaccurate readings. As changes in barometric pressure would affect the sensor’s output, even if the container’s pressure remains constant.

More Pressure Measurement Solutions

In conclusion, understanding the differences and relationships between gauge and absolute pressure is crucial for various applications and industries. Selecting the right pressure measurement type ensures accurate results and optimal system performance.

When it comes to pressure transmitters, Sino-Inst is a professional manufacturer with extensive experience. Our expertise can help you choose the ideal pressure transmitter for your specific needs.

To learn more about their products and how they can support your pressure measurement requirements, visit our Sino-Inst website and explore wide range of pressure sensors and instruments. Make the right choice for your projects and achieve accurate pressure measurements with confidence.

-1.jpg)