The DP Density Meter is a field instrument for measuring the density of various liquids or liquid mixtures, directly applicable to industrial production processes. Utilizing the differential pressure principle, it calculates the liquid density and concentration based on the differential pressure across a specific vertical distance, automatically performing temperature compensation. It boasts high accuracy, reliability, and ease of installation and use.

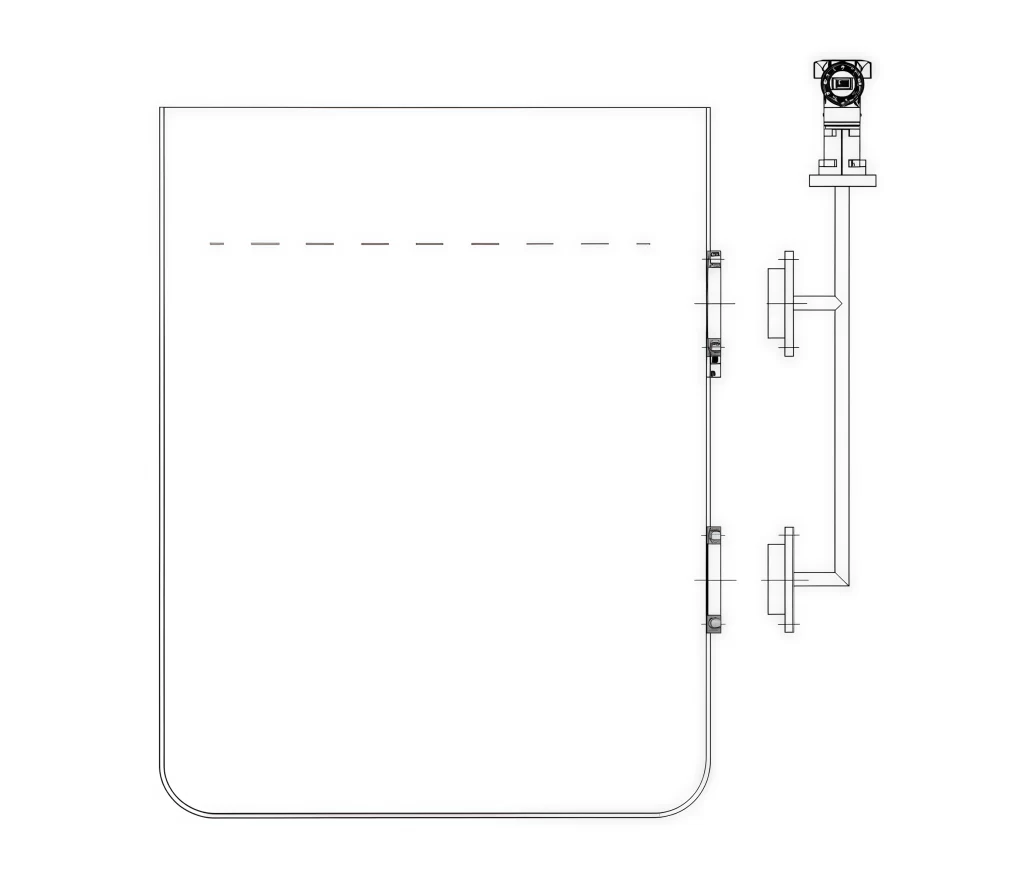

Widely used in industrial settings such as pipelines, open or closed storage tanks, it provides continuous, real-time online measurement of liquid density in pipelines or tanks.

Features

- Input 24V, output 4-20mA, two-wire HART communication protocol, compatible with PLC/DCS control systems.

- Generates corresponding 4-20mA signals based on concentration and density levels, enabling remote calibration and diagnostics via digital communication.

- Side-mounted differential pressure density meters are suitable for flowing or stationary liquids, ideal for tank and vessel installations.

- Features an integrated two-wire transmitter with no moving parts for simplified maintenance.

- Continuously measures liquid density and temperature online without process interruption, enabling direct use in production process control.

- Five-digit LCD display.

- Simultaneously displays temperature and density parameters, facilitating industry-standard density conversion.

- Multiple wetted material options available: 316L stainless steel, tantalum, Hastelloy, PTFE, Monel diaphragms.

- Robust design with outstanding overpressure protection, superior temperature stability, and fully welded seals.

- Suitable for measuring high-temperature, low-temperature, and high-viscosity media with impurities.

- Fixed sensing diaphragm design, factory calibrated for easy field configuration.

- Easy to install and use—simply connect the density meter’s two probes to the liquid for immediate readings.

- Simplified maintenance with no routine cleaning required (except for high-viscosity media, which may require periodic or shutdown cleaning).

- Online density meter calibration requires no standard reference source, no laboratory calibration, and no process interruption.

- Intrinsically safe and explosion-proof models are available for hazardous locations.

Specifications

| Density Range: | 0~3g/cm² |

| Electrical Interface: | 1/2NPT or M20X1.5 |

| Accuracy: | 0.005g/cm² |

| Operating Temperature Range: | -50℃~+250℃ (different medium temperatures are available, divided into low temperature, normal temperature, and high temperature types) |

| Working Pressure: | 7.0MPa (other pressures can be customized) |

| Fluid Viscosity Range: | 0–20000cP |

| Built-in Temperature Sensor: | PT1000 |

| Wetted Materials: | 316L, Hastelloy C-276, Tantalum, Titanium, PTFE (Teflon) |

| Process Interface: | Various flange specifications (flange specifications and dimensions can be customized) |

| Filling fluid: | DC200 silicone oil (olive oil for hygienic type) |

| Power supply: | 12~36VDC |

| Operating Voltage: | 12~45VDC |

| Output Signal: | Dual-wire 4~20mA, superimposed Hart protocol digital signal, RS485 Modbus RTU |

| Display Type: | High-definition backlit LCD display |

| Output Accuracy (20°C): | ±0.5% or ±0.2%FS of reading |

| Output Repeatability (-40 ~+85°C): | ±0.1%FS |

| Housing: | Aluminum alloy |

| Protection Rating: | IP67 |

| Explosion-Proof Rating: | EXdⅡCT6 |

Density Measurement Principle Using Differential Pressure Transmitters

A differential pressure density meter is essentially a high-precision differential pressure transmitter. Its working principle is as follows: the pressure exerted by a liquid column of fixed height is directly proportional to the density of the liquid.

P = ρgh

Where:

- P— Pressure exerted by a liquid column of fixed height

- ρ— Density of the liquid

- g— Gravitational acceleration at the measuring location

- h— Height of the liquid column

Based on the pressure value measured by the pressure gauge, and given the gravity acceleration at the measuring location and the height of the liquid column, the density value of the measured liquid can be obtained.

Read more about:

- DP Transmitter for Flow Measurement

- Differential Pressure Level Transmitter: Understanding, Principles and Uses

- Industrial Differential Pressure Sensors

- Differential Pressure Transmitters – Guide and Selection

- DP Transmitters for Filter Differential Pressure Monitoring

DP Density Meters Applications

Side-mounted online density meters are widely used in industrial settings such as on-site pipelines, open or closed storage tanks, and can continuously and in real-time measure the density of liquids in pipelines or tanks.

- Sugar and Brewing Industries: Extracting juice, syrup, grape juice, lime juice density, alcohol content, molasses, hexane/ethanol interface, etc.;

- Dairy Industry: Condensed milk, lactose, cheese, dry cheese, lactic acid, etc.;

- Mining: Coal, potash, brine, phosphates, calcium compounds, limestone, copper, gold, etc.;

- Refining: Lubricants, aromatics, fuel oils, vegetable oils, etc.;

- Food Processing: Tomato juice, grape juice, lemon juice, ketchup, molasses, vegetable oils, fructose syrup, jellies, jams, etc.;

- Pulp and Paper Industry: Black liquor, green liquor, pulp washing, evaporators, caustic soda, etc.;

- Beverage Processing: Beer, soft drinks, fruit wines, instant coffee, malt, etc.;

- Chemical Industry: Caustic soda, acids, urea, detergents, polymer density, ethylene glycol, sodium chloride, sodium hydroxide, etc.;

- Petrochemicals: Natural gas, oil-gas-water separation, kerosene, lubricating oil, oil/water interface, etc.

More density measurement instruments

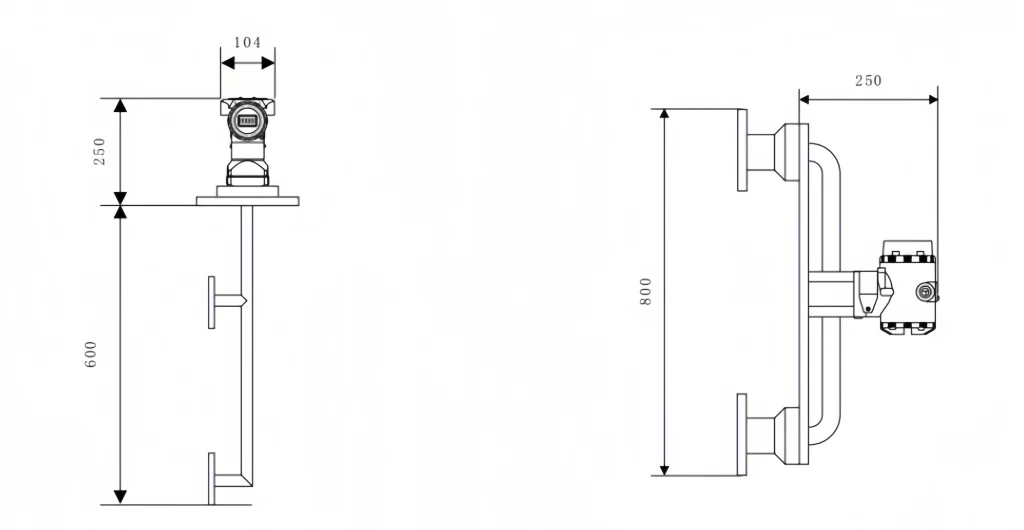

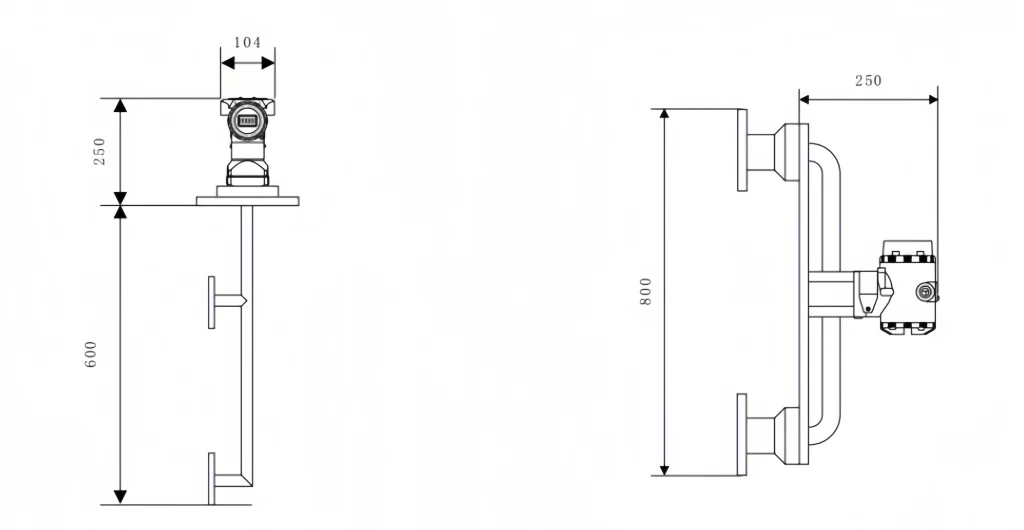

Differential pressure density meters are field instruments used to measure the density of various liquids or liquid mixtures, and can be directly applied to industrial production processes. The intelligent online density meter consists of a high-precision capacitive differential pressure sensor and a pair of pressure repeaters connected to it and inserted into the production process. A temperature sensor is located between the two pressure repeaters to compensate for temperature changes in the process liquid.

Sino-Inst’s differential pressure density meters continuously measure liquid density online, have no moving parts, are easy to install and use, and are simple to maintain. Equipped with a cleaning device, the probe can be cleaned periodically to ensure accuracy.

If you need density measurements, please feel free to contact us.

DP Density Meter-Tank Density Measurement Instrument

The DP Density Meter is a field instrument for measuring the density of various liquids or liquid mixtures, directly applicable to industrial production processes. Utilizing the differential pressure principle, it calculates the liquid density and concentration based on the differential pressure across a specific vertical distance, automatically performing temperature compensation. It boasts high accuracy, reliability, and ease of installation and use.

Product SKU: DP Density Meter-Tank Density Measurement Instrument

Product Brand: Sino-Inst

Product In-Stock: InStock

5

-1.jpg)