Radar level gauges, with their non-contact measurement, high accuracy, and adaptability, have become the preferred technology for tank level monitoring. Using high-frequency microwave pulse or continuous wave technology, radar level gauges accurately measure levels by calculating the time difference between the electromagnetic wave’s transmission and its reflection back to the receiving antenna.

In large tank applications, their measurement accuracy can reach ±2mm, far exceeding that of traditional float-type or differential pressure level transmitters.

Radar Level Gauges

Radar Level Measurement

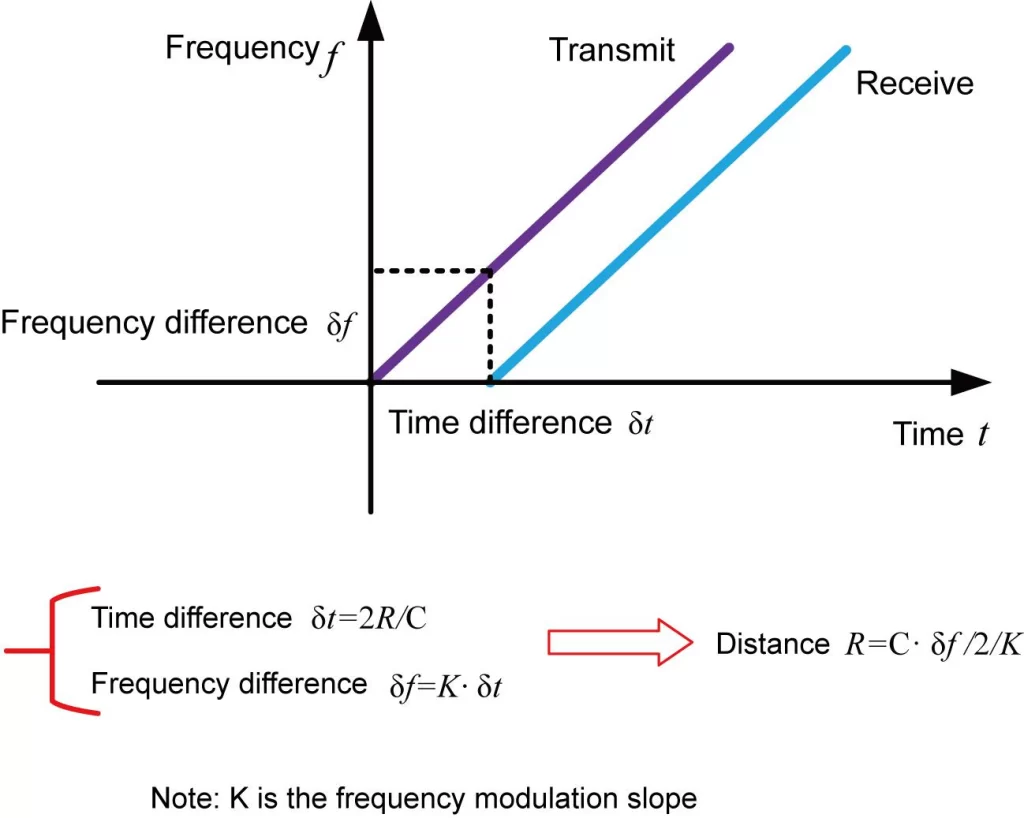

The general principle of the FM continuous wave radar level gauge is that the radar emits electromagnetic waves on the top of the tank, and these electromagnetic waves are received by the radar after being reflected by the medium. The frequency difference δf between the received signal and the transmitted signal is proportional to the distance R from the surface of the medium:

R=C (speed)*δf (frequency difference)/2/K (frequency modulation slope).

Since the speed of light C and the frequency modulation slope K are known, the frequency difference δf can be estimated. This provides the distance R from the radar installation location to the material surface. The material level can then be calculated by subtracting the distance from the radar to the material surface (called the head height) from the known total tank height.

Benefits

- Millimeter-wave radar, with a measurement accuracy of up to ±1mm, and a minimum blind area of 0.1m.

- The smaller antenna size satisfies the measurement of more working conditions.

- A variety of lens antennas, smaller launch angle, more concentrated energy, stronger echo signal, under the same industrial and mining conditions, compared to Other radar products, have higher reliability.

- With stronger penetrability, it can be used normally even if there is adhesion and condensation.

- The dynamic signal range is larger, and the measurement of low dielectric constant medium is more stable.

- A variety of measurement modes, the radar reaction time in the fast measurement mode is less than 1s.

Featured Applications of Radar Gauge for Level Measurement

In large crude oil storage tank applications, Radar Gauges achieve a measurement accuracy of ±2mm, far exceeding traditional float-type or differential pressure level gauges. Actual measurement data from a petrochemical company shows that on a 30-meter diameter tank, the long-term stability error of radar level gauges is less than 0.05%FS, providing a reliable data basis for custody transfer.

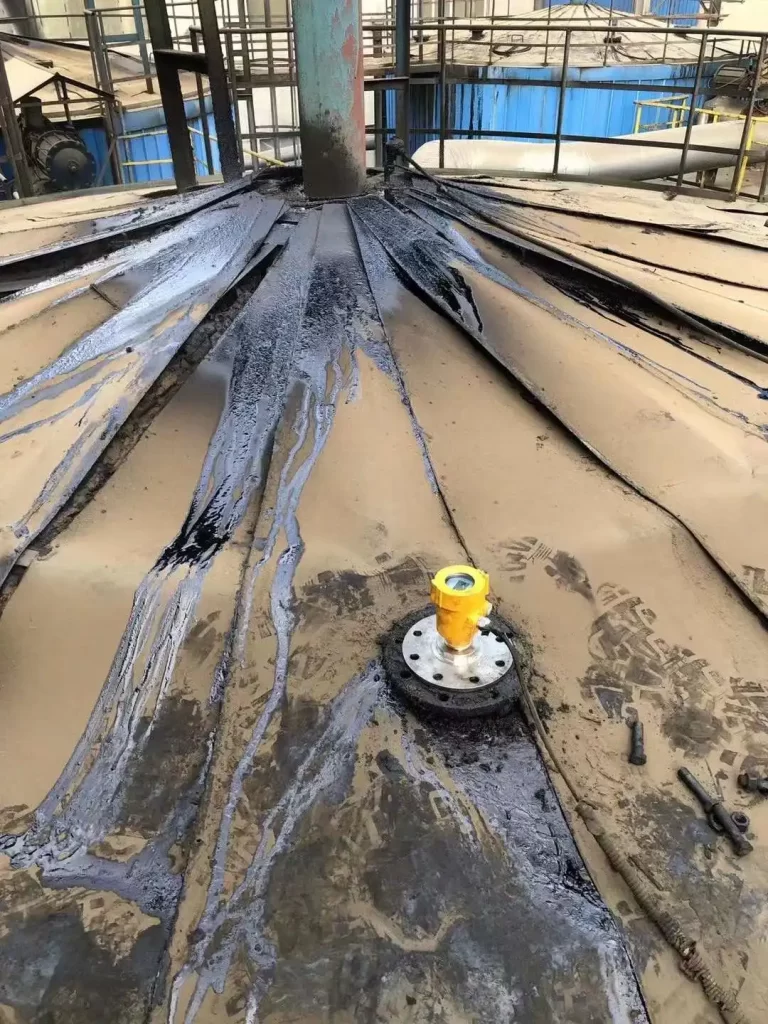

Radar level gauges demonstrate significant advantages in adaptability to complex operating conditions. Their non-contact measurement method completely eliminates the problem of probe contamination caused by viscous media such as asphalt and heavy oil. Operational records from a lubricating oil tank farm show that radar level gauges have operated continuously for 18 months without drift, even under conditions with a viscosity as high as 460 cSt.

Furthermore, 80GHz high-frequency radar products effectively suppress interference echoes from agitator vortices and tank internal structures, ensuring measurement reliability in dynamic environments such as chemical reactors.

Breakthroughs in safety performance are the core competitive advantage of radar level gauges. The fully enclosed electronic design ensures perfect compliance with explosion-proof certification requirements, making them irreplaceable for use in tanks storing flammable and explosive media such as gasoline and methanol. An HSE report from a multinational oil depot shows that the implementation of radar level gauges reduced VOC emissions from tank farms by 83%.

The intelligent integration of radar level gauges makes them a key node in digital tank farms. Using communication protocols like HART, measurement data can be directly connected to the DCS system, enabling dynamic inventory monitoring with the Tank Management System (TMS). In a commercial storage project, a network of 48 radar level gauges has streamlined the previously four-hour manual measurement process to real-time automated data collection, improving inventory efficiency by over 90%.

Radar level gauges demonstrate excellent corrosion resistance in acid tank environments. Key components utilize PFA linings and a protective structure of 316L stainless steel combined with PTFE or PFA, effectively resisting highly corrosive media such as sulfuric acid and hydrofluoric acid. Compared to traditional level gauges, this highly corrosion-resistant material combination significantly extends service life, reduces maintenance frequency, and minimizes downtime costs.

Furthermore, radar level gauges are capable of operating in extremely high-temperature conditions, reaching up to +400°C. This ensures stable measurement accuracy even under the drastic temperature fluctuations found in alkylation or pickling tanks.

More Level Measurement Solutions

Sino-Inst specializes in instruments for level, flow, pressure, temperature, density, water analysis, and environmental monitoring. Our radar level measurement system, specifically designed for tank farms, offers unique features. Our radar level gauges serve over 150 different applications, including crude oil, refined oil, chemical raw materials, and grain and oil filling systems.

If you require tank level or material level measurement, please feel free to contact us.

-1.jpg)