“RTD” stands for “resistance temperature detector.” It is a type of temperature sensor. And it uses the electrical resistance of metal to measure temperature. RTDs offer high accuracy and stability. But they are more expensive than other sensors, such as thermocouples. They are widely used in various industries, including automotive, aviation, and food processing.

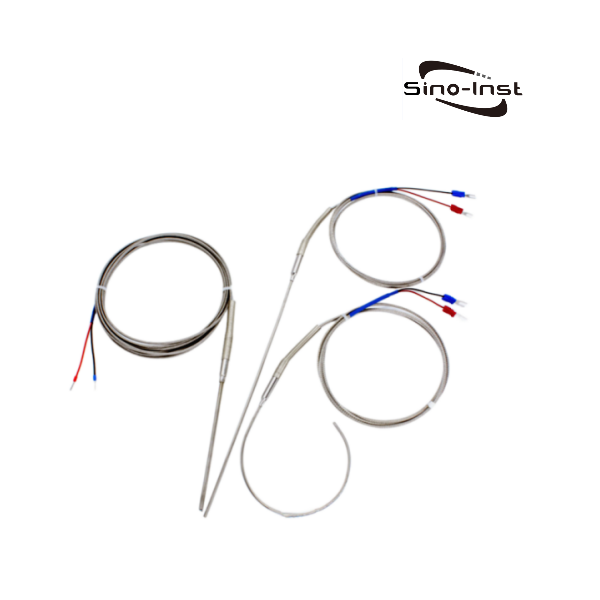

The sensing element of an RTD sensor is typically made of platinum, copper, or nickel. The temperature range is -196°C to 600°C. Some special designs can even reach 1000°C. At Sino-Inst, we primarily offer three-wire RTD PT100 temperature sensors. Our sensors can be customized. This includes temperature range, insertion depth, connection thread, and cable length.

What Is an RTD Temperature Sensor?

An RTD is a sensor whose resistance changes with temperature. The sensor’s resistance increases as the temperature rises. Most RTDs use platinum as the sensing element. Platinum offers high stability and a wide operating range.

An RTD is a passive device. It does not generate an output on its own. So, the external electronics are typically used to measure the sensor’s resistance. A small current can be applied to the sensor to generate a voltage. The typical measurement current is 1 mA or less, with a maximum of 5 mA.

What Does Rtd Stand for Temperature?

In temperature measurement, RTDs can accurately detect temperature. The measurement range of an RTD is -200°C to 850°C, but the specific range depends on the sensor’s construction and element type.

Platinum is a common and stable material for RTD elements. It also has a stable resistance-temperature relationship. Nickel and copper, on the other hand, have more limited measurement ranges, but are still practical.

Platinum (Pt) offers the widest measurement range and excellent stability. Its temperature range is -200°C to 850°C.

Nickel (Ni) is suitable for medium temperature ranges, with a temperature range of -80°C to 260°C.

Copper (Cu) provides a good medium temperature range, typically -200°C to 260°C.

How Does an RTD Temperature Sensor Work?

RTDs operate on the principle that the resistance of metal increases with temperature. An electric current is passed through a sensing element, typically made of platinum. As the temperature changes, the element’s resistance also changes. This change in resistance is measured and converted into a corresponding temperature reading.

Resistance-Temperature Relationship: Resistance has an approximately linear relationship with temperature.

The formula is as follows:

R(T)=R0[1+α(T−T0)]

Where (R0) represents the resistance at a reference temperature (usually 0°C). α represents the temperature coefficient (α for platinum is approximately 0.00385/°C).

RTD Sensor Wiring Configuration

There are three standard RTD connection methods: 2-wire, 3-wire, and 4-wire.

Is an RTD the Same as a Thermocouple?

No, RTDs and thermocouples are not the same. They are two different types of temperature sensors.

| Key Differences | RTDs | Thermocouples |

| Working Principle | RTDs are based on the fact that the resistance of metals changes with temperature. | When two dissimilar metals are exposed to a temperature gradient, they develop a voltage. |

| Construction | RTDs are passive devices. | Thermocouples consist of two dissimilar metal wires. |

| Power Supply | RTDs require external electronics to pass a small current to measure their resistance. | Thermocouples are self-powered. |

| Temperature Range | RTDs are generally suitable for medium temperature ranges. However, they offer high accuracy even at their extremes. | Thermocouples have a wider temperature range and are suitable for extreme conditions. |

| Accuracy and Response Time | RTDs offer high accuracy.Response time can be slow. | Thermocouples offer a fast response time.Accuracy is generally lower than that of RTDs. |

| Cost | High | Low |

The Uses and Benefits of RTDs

Uses and Applications

- Industrial processes. Used for temperature monitoring in chemical processing and food manufacturing.

- Pharmaceuticals and biotechnology.

- HVAC systems. Used for temperature monitoring and control in building automation systems.

- Power generation.

- Environmental monitoring.

- Laboratories.

Benefits

- High accuracy. Common platinum sensors have an accuracy of ±0.1°C to ±0.3°C.

- Wide temperature range.

- Linear output.

- Long-term stability.

How to Use an RTD Temperature Sensor?

Before using an RTD temperature sensor, you need to understand the following steps.

1. Understanding the Principle

RTDs operate on the principle that the resistance of metal changes with temperature.

2. Connecting the RTD

A two-wire connection is the simplest but least accurate configuration. For more accurate measurements, choose a three-wire or four-wire connection.

3. Measuring Resistance

Resistance can be measured using Ohm’s law (V=IR).

Resistance (R) can be calculated from the measured voltage (V) and the known excitation current (I).

4. Converting Resistance to Temperature

You will need to refer to the RTD’s specific lookup table to find the corresponding temperature.

How Do I Calibrate an RTD Temperature Sensor?

The steps for calibrating an RTD are as follows:

- Isolate the RTD from the process. This prevents process variables from affecting calibration.

- Place the reference probe and the RTD to be calibrated in the temperature source.

- Connect the leads to the readout using an appropriate 2-wire, 3-wire, or 4-wire connection.

- Adjust the temperature source to the specific test point and allow the system to stabilize.

- Record the reference standard and RTD readings at each test point.

- Compare the RTD’s output to the reference standard’s reading to determine the RTD’s error.

- Record the calibration results and calibration history for traceability and quality audits.

More Temperature Measurement Solutions

RTDs are one of the most popular temperature sensors. They measure temperature by exploiting the fact that the resistance of metal increases with temperature. They offer high accuracy, stability, and durability.

Sino-Inst primarily offers Pt100 RTD temperature sensors. They can be connected to transmitters using two-, three-, or four-wire systems. Three-wire connection is the most common wiring method for Pt100 temperature measurements.

Sino-Inst manufactures and offers thermocouples, RTDs, and other temperature sensors and transmitters in various sizes. We also support custom specifications. If you need to purchase a temperature sensor or have any technical questions, please feel free to contact us!

-1.jpg)