An Annubar is a type of insertion flow meter founded on the averaging pitot principle. That’s why Annubar flow meter are sometimes referred to as Averaging pitots. It is used to measure the flow of liquid, gas or steam that flows through a pipe.

The name annubar has become synonymous with averaging pitot tubes despite other manufacturers selling their own version of Annubar Flow Meter. This blog will provide an overview of Annubar flow meter.

Introduction: Annubar Flow Measurement

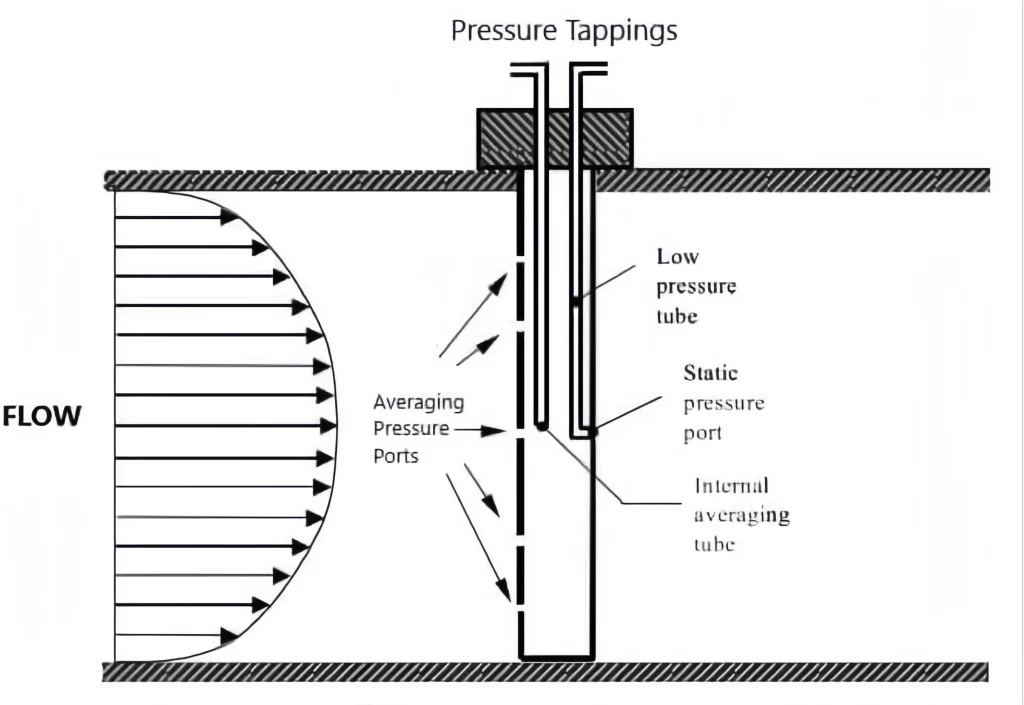

Annubar flow measurement is a discipline that apply s a multi-port averaging pitot tube to measure fluid flow in a pipe. It is a kind of differential pressure flow meter that calculates flow by measuring the difference in pressure between the static and impact pressure ports.

It is particularly favored in applications with large-diameter pipelines and where pressure loss needs to be minimized. The Annubar meter is used for measuring the flow of gases, liquids, and steam in industrial environments.

Evolution of Annubar Technology

The idea of pitot tubes dates back to the 18th century, developed by Henri Pitot. Over time, the original pitot tube design evolved into much advanced versions with better averaging and multi-port sensing capabilities.

The Annubar—a trade name coined by Emerson for their brand of averaging pitot tubes—became popular in the 1970s as industries looked for more cost-efficient alternatives to orifice plates and venturi tubes.

Annubar Flow Measurement’s Importance

- Flow Characteristics

- Installation Cost

- Low Pressure Loss

- Suitable for Large Diameter Lines

The forces exerted on a primary flow element can be large, especially in large diameter lines. Annubars are available in models that extend the entire diameter of the pipe for support at both ends. This makes them robust, yet economical for use in larger pipelines.

Functional Principle of Annubar Flow Meter

The Basic Formula:

Q=C⋅A⋅2⋅ΔP/ρQ = C \cdot A \cdot \sqrt{2 \cdot \Delta P / \rho}

Where:

QQ = Flow rate

CC = Discharge coefficient

AA = Cross-sectional area

ΔP\Delta P = Differential pressure (high – low)

ρ\rho = Fluid density

The Annubar probe is inserted into the pipe and spans the diameter. It measures the impact pressure (P1) on the upstream side and the static pressure (P2) on the downstream side. The difference P1−P2P1 – P2 gives the differential pressure used to calculate flow.

Ingredients of an Annubar Flow System

- Averaging Pitot Tube (Probe): Contains multiple ports for sensing pressure at different points.

- Differential Pressure Transmitter: Measures the differential pressure and converts it into an electrical signal.

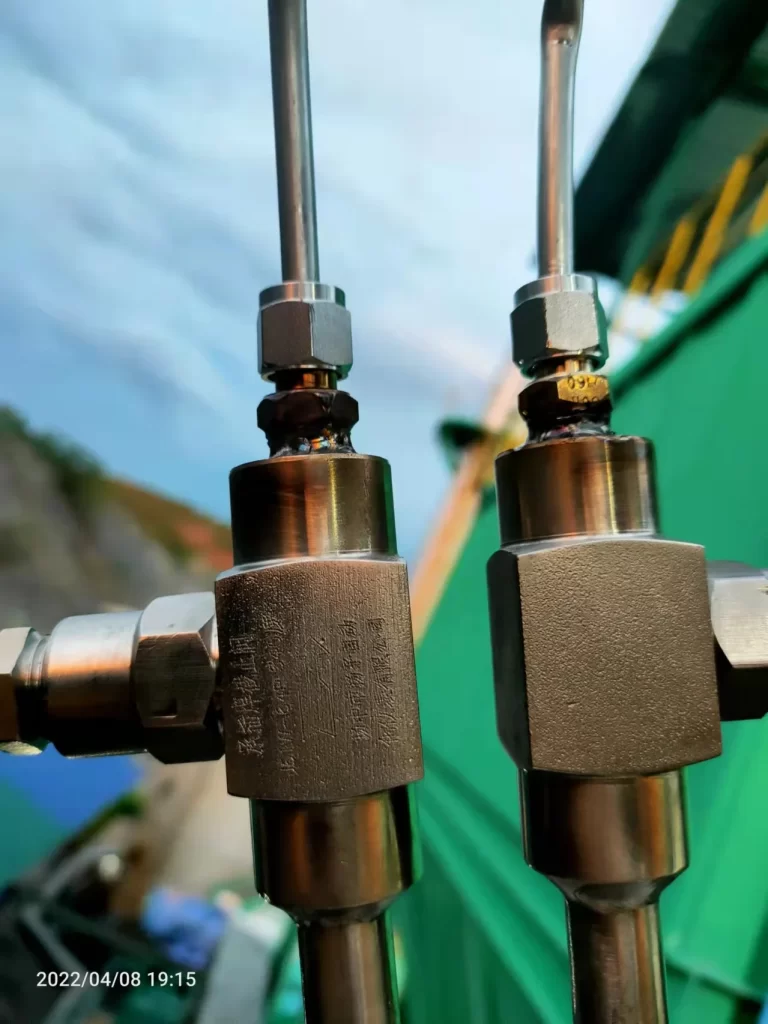

- Mounting Hardware: Flanges, couplings, or hot tap fittings.

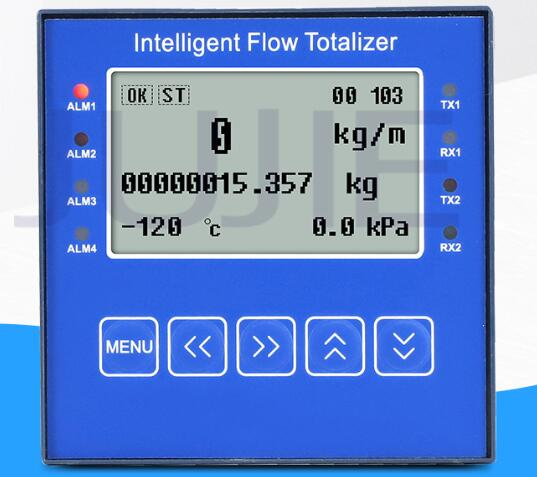

- Flow Computer (optional): Used to calculate mass or volumetric flow with compensation for pressure and temperature.

- Temperature and pressure compensation: For general gas measurement, we can install temperature sensors and pressure sensors, and perform compensation calculations through flow meter integrators.

Key Advantages of Annubar Flow Meters

- Small size of annubar flow meter makes it suitable for insertion in small openings. So suitable for large pipelines flow rate measurement.

- Simple structures, easy installation, little maintenance needed.

- Low pressure loss.

- It can be used to determine the flow rate and velocity of the fluids in different several points.

- The annubar flow meter has high accuracy because there is minimal obstruction.

- The internal structure of the annubar flow element provides a very high precision.

- The annubar flow meter is resistant to corrosion and can be used in high-temperature areas

- The accuracy of the annubar flow element is unaffected by the forces of wear and tear.

- The flow meter is also easy to install and comes in a variety of designs.

- Wide range of applications. It can be used to measure gas,steam and liquid

Limitations and Challenges of Annubar Flow Meters

- Lower Accuracy than Coriolis or ultrasonic meters, especially in low-flow or transitional flow conditions.

- Sensitivity to Flow Profile Disturbances.

- Installation Sensitivity – Requires a specific number of straight pipe lengths upstream and downstream to ensure accurate measurement.

- Not Ideal for Dirty Fluids.

Applications of Annubar Flow Meters

The annubar flowmeter can be used in various applications such as measuring the flow rate of oil flowing in a pipeline, in airplanes, and industrial applications.

An annubar flowmeter is also used in scientific research where the flow rate of the fluids needs to be measured. The flowmeter can also be used in determining the flow rate of fluids being emitted into the environment. For instance, an annubar flow element can be used to monitor the emission of gases from chimneys.

Annubar flow meters are also important in agricultural and industrial production. They are used to determine the quantity of the inputs being used or as a control system to automate the process.

The annubar flow meter can also be used in the mining industry to determine the flow of compressed air, blast furnace gas, and other liquids.

It is widely used in electronic power, petroleum, water treatment, chemical industry, environment protection and so on.

Installation Best Practices

- Straight Pipe Requirements

Typically 10–20 diameters upstream and 5 diameters downstream of straight pipe are recommended. - Proper Orientation

- Hot Tap Installation

- Seal and Gasket Considerations

- Positioning

Avoid elbows, valves, or pumps near the probe to reduce flow disturbances. - Wiring

It is necessary to complete the wiring of the differential pressure transmitter, temperature sensor, and pressure sensor to the flow totalizer. - Parameter Setting

Generally, it is necessary to set the calculation parameters in the flow meter totalizer according to the actual measurement parameters.

More DP Flow Meters and Flow Measurement Solutions

- Rotameters: Excellent Choice for Flow Measurement in Various Gases

- Flow Meter Selection Guide: Starting from Measurement Conditions

- 4 Types of Manifolds for Pressure Transmitters

- Industrial Water Pressure Measurement and Monitoring

- Choose Digital Water Pressure Switch for Better Control

- What Is Temperature Compensation in a Pressure Transmitter?

- Case Study – Mass Flow Meter For Slurry

- LNG and CNG Flow Measurement

- Thermal Dispersion Flow Meters, Flow Switches & Controllers

As industries continue to prioritize energy efficiency and real-time monitoring, the role of cost-effective flow meters like Annubar will only become more noticeable.

If you’re planning to implement or upgrade your flow measurement system, consider how an Annubar can fit into your process. Always consult with full-fledged artifact specialists to tailor the setup to your exact needs.

Sino-Inst’s flow meters service is mostly for industrial applications. Our sales team is always ready for customers in finding best flow measurement solutions.

-1.jpg)