An ultrasonic liquid flow meter is a non-contact flow measurement instrument. It uses ultrasonic waves to measure the velocity of a given fluid or gas. It calculates the flow rate by detecting the difference in forward and reverse sound wave propagation. It has no pressure loss and is widely applicable. It is widely used in various fluid and gas applications. Currently, there are two types of ultrasonic flow meter technologies: Doppler and transit time.

In this article, we will mainly introduce and analyze the ultrasonic liquid flow meter used to measure liquids. Ultrasonic liquid flow meters include clamp-on, insertion, and in-line types. Ultrasonic liquid flow meters include portable ultrasonic liquid flow meters.

Understanding Ultrasonic Liquid Flow Meters

An ultrasonic liquid flow meter is a volumetric flow meter. It measures flow rate based on the effect of the flowing medium on the velocity of ultrasonic waves, or ultrasonic pulses. Core components include an ultrasonic transducer, a signal processing unit, and a display system.

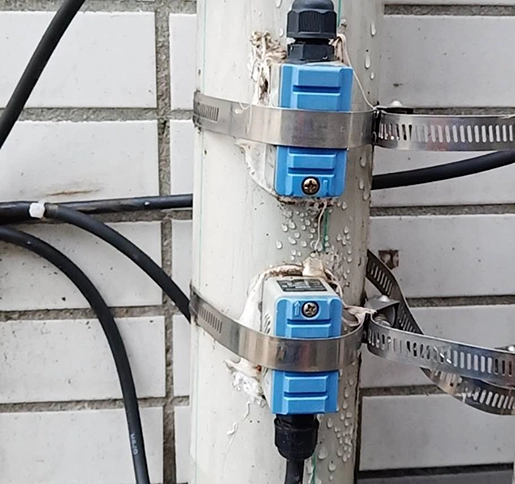

Ultrasonic liquid flow meters offer non-contact measurement. Clamp-on transducer ultrasonic flow meters do not require pipe cutting or flow interruption. Instead, they simply install the transducer outside the existing pipe. This is a unique advantage of ultrasonic flow meters among industrial flow meters. Therefore, this allows for mobile measurement.

Ultrasonic liquid flow meters measure flow without obstruction. They eliminate excess pressure loss and can measure non-conductive liquids. Moreover, they are suitable for large circular and rectangular pipes and are generally not limited by pipe diameter. They are a preferred option when actual flow verification is not possible.

Portable ultrasonic liquid flow meter

Portable ultrasonic liquid flow meters are used in water and gas applications across a wide range of industries. Clamp-on ultrasonic flow meters vary depending on the media type and application.

A portable clamp-on ultrasonic liquid flow meter is a non-contact flow measurement device that uses a clamp-on sensor. It measures flow by detecting the effect of fluid flow on the ultrasonic beam.

Clamp-on sensors utilize a non-invasive installation method. They clamp directly onto the outside of the pipeline without cutting or stopping the flow. Thus, they do not damage the pipeline structure. They are suitable for mobile monitoring of pipeline fluids in the petroleum, chemical, and nuclear power industries. Their portability makes them an excellent choice for measuring flow throughout pipeline infrastructure.

Features

- Powered by a rechargeable lithium battery. Offers 50 hours of continuous operation.

- Features non-contact measurement. Installation requires no pipe disruption or flow interruption.

- Measurement accuracy reaches 0.5-2% FS. High-temperature and zero-point stability are also provided.

- Adaptive signal gain adjustment.

- Easy operation. Simply enter the inner diameter to start flow measurement.

Technical Specifications

| Attributes | Related Parameters |

| Accuracy | Typically ±0.5% to ±3% (the time-of-flight method offers higher accuracy). |

| Applicable pipe diameters | DN15 to DN6000. |

| Repeatability | Better than 0.2%. |

| Straight pipe requirements | Typically ≥10D upstream and ≥5D downstream (multi-channel models can be reduced to 5D upstream and 2D downstream). |

| Temperature resistance | -50°C to 160°C |

| IP rating | IP68. |

| Installation methods | Clamp-on (non-invasive), insert-on, and pipe segment (for high-temperature or high-pressure applications). |

| Pipe materials | Steel, stainless steel, PVC, fiberglass, and other dense materials. |

How Do Ultrasonic Liquid Flow Meters Work?

Ultrasonic liquid flow meters operate based on the transit time method and the Doppler effect.

The transit time method calculates flow velocity by measuring the time difference Δt between the upstream and downstream waves of an ultrasonic wave.

The formula is v = c²Δt/(2Lcosθ).

c is the speed of sound. L is the length of the sound path. θ is the angle of incidence of the sound wave.

The flow rate Q is then calculated as Q = v×A (where A is the cross-sectional area of the pipe).

The transit time method has high accuracy, reaching ±0.5% to ±1%. It is suitable for clean liquids such as pure water and diesel.

The Doppler method uses the frequency shift (Δf) of ultrasonic waves reflected by suspended particles in the fluid to estimate flow velocity.

The formula is v = Δf⋅c/(2f₀cosθ) (where f₀ is the transmission frequency).

The Doppler method has an accuracy range of ±1% to ±5%. It is suitable for wastewater and liquids containing bubbles or particles.

Both Doppler effect and transit time ultrasonic liquid flow meters are available with clamp-on or insertion sensors. They are suitable for measuring large pipe diameters and difficult-to-reach fluids.

Ultrasonic Liquid Flow Meter for Water

Both Doppler ultrasonic flow meters and transit-time ultrasonic flow meters can be used to measure water flow. However, their application scenarios differ.

Doppler ultrasonic flow meters are based on the Doppler effect. They are suitable for measuring liquids containing solid particles or bubbles. However, they are not suitable for measuring pure water.

Transit-time ultrasonic flow meters calculate flow velocity by measuring the difference in sound wave propagation time between upstream and downstream. They are suitable for pure water or water with small amounts of impurities.

However, the water velocity is relatively low (typically <5 m/s). The pipe diameter is relatively small (typically <1 m). Furthermore, the water level and flow velocity do not fluctuate significantly.

They use a clamp-on sensor, eliminating the need to cut off the pipe or stop the flow. They can measure liquids containing suspended particles or bubbles. Such as drinking water, river water, and seawater.

Ultrasonic Flow Meter for Diesel

Diesel fuel is widely used. It fuels large, heavy machinery such as haul trucks, excavators, and loaders. Non-intrusive ultrasonic flow meters easily measure diesel flow without interrupting the diesel supply. Using ultrasonic flow meters enables more efficient fuel distribution systems.

Ultrasonic flow meters are compact and lightweight. They support time difference measurement with an accuracy of ±1%. They offer automatic data storage, multiple communication protocols (MODBUS/HART, etc.), and heat metering. These portable ultrasonic flow meters support clamp-on installation and can reach peak flow rates of 32 mm/s.

Doppler ultrasonic flow meters can also be used to monitor the flow of fuels such as diesel. They utilize the Doppler effect and support clamp-on measurement of liquids.

Applications

Industrial pipeline monitoring. Ultrasonic liquid flow meters are suitable for use in the petroleum, chemical, and environmental protection industries. They can be used to measure liquid flow in metal or plastic pipes.

Environmental monitoring. Ultrasonic liquid flow meters can also be used to monitor flow in open channels or natural waterways. Such as drinking water, river water, and industrial wastewater. They support non-contact installation to avoid sensor wear and offer an accuracy of ±1%.

Water and wastewater measurement. Ultrasonic liquid flow meters measure wastewater flow in wastewater treatment plants. They are used to monitor and control water quality, flow, and the operation of water supply systems.

Complex environment. Supports flow measurement of high temperature (160°C), low temperature (-40°C), and corrosive liquids. Suitable for chemical production, geological exploration, and other scenarios.

Advantages of Ultrasonic Liquid Flow Meter

- Non-contact measurement and no pressure loss

Ultrasonic liquid flow meters achieve non-invasive measurement using an external sensor. This eliminates the need to cut pipes or come into contact with the fluid. Moreover, this eliminates pressure loss caused by mechanical components.

- High Accuracy and Wide Turndown Ratio

Ultrasonic liquid flow meters offer measurement accuracy within ±1% and a wide turndown ratio (e.g., 30:1). They can accommodate a wide range of flow rates, from low to high.

- Multi-fluid adaptability

Ultrasonic liquid flow meters can measure clean, pure liquids and gases. They can also measure liquids with small amounts of impurities, and even non-conductive liquids such as oil.

- Wide measuring range.

Ultrasonic liquid flow meters have a wide measuring range, covering pipe diameters from 6 mm to 6 meters.

- Not affected by the media

The volume flow measured by the ultrasonic liquid flow meter is not affected by the thermophysical parameters of the measured fluid. Such as temperature, pressure, viscosity, and density.

What factors should be considered when installing an ultrasonic liquid flow meter?

1. Pipeline Conditions

You should select a pipe section that is filled with fluid. Such as a vertically upward flow section or a horizontal section. Avoid installing at the highest or lowest points in the pipeline.

A straight pipe section of 10 times the pipe diameter is required upstream. A straight pipe section of 5 times the pipe diameter is required downstream. This can reduce eddy current interference.

2. Installation Location

Ultrasonic liquid flow meters should be installed away from pumps, valves, high-voltage electrical equipment. Mechanical vibration or electromagnetic interference should be avoided to prevent measurement interference.

3. Environmental Requirements

The pipe temperature should be within the sensor’s operating range (-30°C to 160°C). And the pressure should not exceed the device’s tolerance limit.

4. Signal Transmission

Before installation, polish the pipe surface and apply the coupling agent to ensure close contact between the sensor and the pipe wall.

5. Parameter Settings

After installation, you must regularly maintain the sensor. Check that the pipeline parameters are consistent with the device settings.

Read More about: Quick Guide: Clamp on Ultrasonic Flow Meter Installation

More Liquid Flow Measurement Solutions

Ultrasonic liquid flow meters continue to be the preferred measurement tool due to their accuracy, reliability, and wide range. The advantage of portable ultrasonic liquid flow meters lies in their non-invasive design. This means there’s no need to cut pipes or stop the flow during installation.

Ultrasonic liquid flow meters offer many advantages. Such as high measurement accuracy, wide measuring range, and sensitive sensing. They provide intuitive readings, are easy to operate, and are not susceptible to damage. They are widely used and suitable for pipes of various sizes and materials. Especially for measuring flow rates in large diameters.

Sino-Inst offers a wide variety of ultrasonic flow meters, including clamp-on and Doppler ultrasonic flow meters. If you need an ultrasonic liquid flow meter and portable ultrasonic liquid flow meter, please feel free to contact one of our sales engineers!

-1.jpg)