SI-3602 High temperature Oval Gear Flow Meter, categorized as positive displacement flow technology.

When liquid flows through this type of positive displacement flowmeter,

these magnets transmit a high resolution pulse output.

The output signal can be processed externally via a remote display controller or PLC or via a variety of output/display options.

Also, oval gear flow meter is particular suitable for measurement of fuel oil.

| Diameter | DN10~DN200 |

| Accuracy | Class 0.5 or 0.2 |

| Temp. range | +100℃-280℃ |

| Pressure | 1.0MPa、1.6MPa、2.5MPa、4.0MPa、6.4MPa |

| Medium | High viscosity liquid and All kinds of oil |

| Explosion-proof | iaⅡCT5,dⅡBT4 |

Features

Specifications

Order Guide

Applications

Reviews

Features

1. High measurement accuracy: 0.2 and 0.5;

2. The mechanism is simple, sturdy and reliable.

3. Particularly suitable for measuring medium with high viscosity

4. Easy to install. There is no need for straight pipe sections before and after the flowmeter, and there is no need to install straight pipe sections.

5, Cast iron oval gear flowmeter, widely used in various oil products and measurement of non-corrosive liquid medium for cast iron

6. Cast steel oval gear flow meter for measuring high pressure and low corrosive medium

7, Stainless steel oval gear flowmeter, widely used in corrosive liquid media, such as acid, alkali, salt

8. In order to prevent the gear of the flowmeter from being jammed by impurities, a filter must be installed upstream of the flowmeter.

9, Explosion-proof grade: ExiaIICT6

Specifications

| Model | SI-3602-TA | SI-3602-TE | SI-3602-TB | |||

| Category | cast iron high temp. | cast steel high temp. | stainless steel high temp. | |||

| Nominal pressure MPa | 1.0 1.6 | 2.5 4.0 6.4 | 1.0 1.6 | |||

| Medium viscosity | 2~200 mpa.s | |||||

| Medium temp. | +100℃-280℃ | |||||

| Flow rate range (m3/h) | SI-3602-TA | SI-3602-TE | SI-3602-TB | |||

| Nominal diameter | Class 0.5 | Class 0.2 | Class 0.5 | Class 0.2 | Class 0.5 | Class 0.2 |

| 10 | 0.08~0.4 | 0.1~0.4 | 0.08~0.4 | 0.1~0.4 | 0.1~0.4 | 0.1~0.4 |

| 15 | 0.27~1.35 | 0.35~1.35 | 0.27~1.35 | 0.35~1.35 | 0.35~1.35 | 0.35~1.35 |

| 20 | 0.54~2.7 | 0.68~2.7 | 0.54~2.7 | 0.68~2.7 | 0.68~2.7 | 0.68~2.7 |

| 25 | 1.08~5.4 | 1.35~5.4 | 1.08~5.4 | 1.35~5.4 | 1.35~5.4 | 1.35~5.4 |

| 40 | 2.7~13.5 | 3.5~13.5 | 2.7~13.5 | 3.5~13.5 | 3.5~13.5 | 3.5~13.5 |

| 50 | 4.4~21.6 | 5.4~21.6 | 4.4~21.6 | 5.4~21.6 | 5.4~21.6 | 5.4~21.6 |

| LA50 | 4.4~21.6 | 5.4~21.6 | 4.4~21.6 | 5.4~21.6 | / | / |

| 65 | 9.2~46 | 11.5~46 | 9.2~46 | 11.5~46 | 11.5~46 | 11.5~46 |

| LA65 | 6.8~34 | 8.8~34 | 6.8~34 | 8.8~34 | / | / |

| 80 | 10.8~54 | 13.5~54 | 10.8~54 | 13.5~54 | 13.5~54 | 13.5~54 |

| LA80 | 8.8~44 | 11~44 | 8.8~44 | 11~44 | / | / |

| 100 | 18~90 | 22~90 | 18~90 | 22~90 | 22~90 | 22~90 |

| 150 | 34~170 | 42~170 | 34~170 | 42~170 | 42~170 | 42~170 |

| 200 | 60~300 | 75~300 | 60~300 | 75~300 | 75~300 | 75~300 |

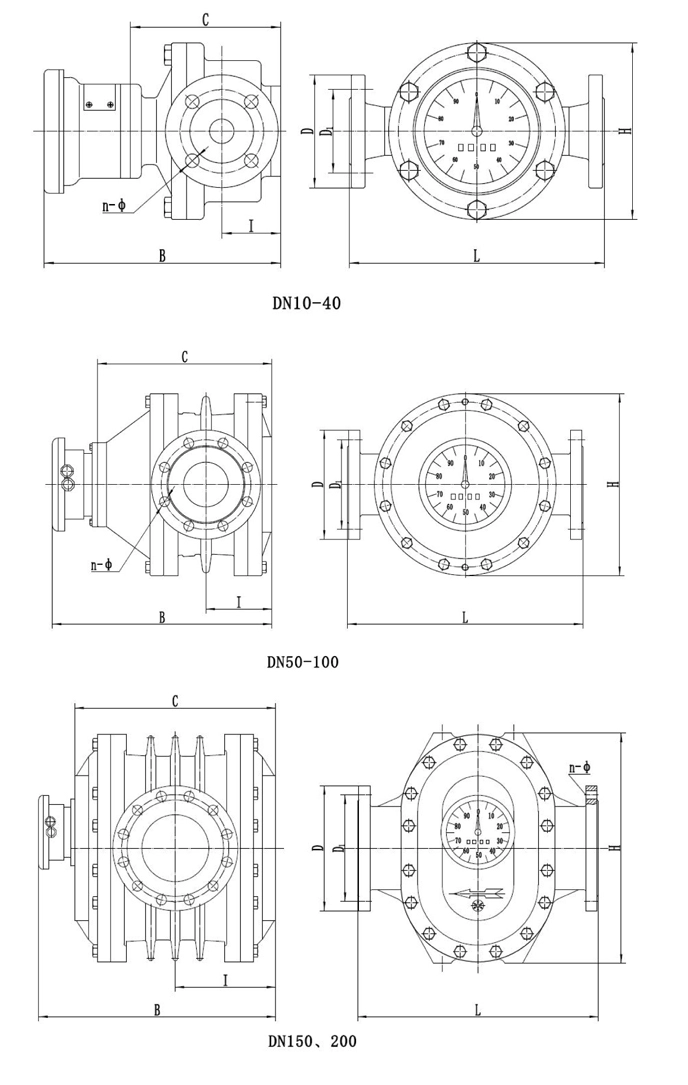

Dimensions

Order Guide

In addition to regular products, we support customization

| SI-3602 | Description | |||||||||

| Housing material | TA | Cast iron | ||||||||

| TE | Cast steel | |||||||||

| TB | Stainless steel | |||||||||

| Diameter | DNX | DN10~DN200(mm) | ||||||||

| Working Pressure | 1 | 1.0MPa | ||||||||

| 2 | 1.6MPa | |||||||||

| 3 | 2.5MPa | |||||||||

| 4 | 4.0MPa | |||||||||

| 6 | 6.4MPa | |||||||||

| Accuracy | A | 0.2 | ||||||||

| B | 0.5 | |||||||||

| Connection | 1 | Flange | ||||||||

| 2 | Thread | |||||||||

| Output | L0 | Pulse | ||||||||

| L1 | 4-20mA | |||||||||

| Communication | R | RS485 | ||||||||

| N | / | |||||||||

| Display | 1 | Pointer | ||||||||

| 2 | LCD | |||||||||

| Explosion-proof | H | iaⅡCT5 | ||||||||

| G | dⅡBT4 | |||||||||

Applications

Industrial gear flow meters are designed for a variety of chemical applications.

Suitable for viscous, non abrasive, clean liquids like:

Water solutions

Petroleum

Petroleum

Oil

Chemicals

Grease

Grease

Fuels

Ink

Pastes

Pastes

- Chemical Production: caustic soda, potassium hydroxide, acetic acid, demineralized water

- Food Industry: sugar solutions, syrups, oils, sauces, beverages, honey, molasses, milk products, juices, chocolate, alcohol, ethanol and coatings

- Pharmaceutical Industry: alcohols, syrups, glycerines and coatings

- Cosmetics Industry: shampoos, gels, perfumes and creams

- Oil and Gas Industry: fuels, lubricants and petro-derivatives

- Water and Wastewater Industry: chemicals, fluoride and acids

- Pulp and Paper Industries: wax finishes, perfumes, dyes and acids in the pulp and paper industries

- Printing: solvents and inks

- Automotive: transmission fluid, glycol, low viscosity climatization liquids and hydraulic oil

- Textiles: dyes, bleach and chemicals

- Petroleum Industry: oils, gasoline, biodiesel, additives and kerosene

- Paint: solvent and latex based paints

- Shipbuilding: lubricating oil, fuels ,marine oil

- Mining Industry: oils, fuels, lubricants

- Metal Industry: heating oil, fuels, oils

- Glue Industry: acrylic water based glue, solvents, cleaning agents

Reviews

Jul 14, 2019 at 11:08 pm

William

Your oval gear flowmeter provides a very simple installation. Just right for our working conditions.

-1.jpg)