What is a thermal gas mass flow meter? A thermal gas mass flow meter is an instrument that measures gas flow rate using the principle of thermal diffusion. It requires no temperature or pressure compensation, making it the preferred product for measuring the flow rate of dry gases. It is widely used in fields such as coal gas, natural gas, compressed air, and semiconductor process gases, effectively monitoring gas flow rate in pipelines.

| Diameter | DN15~DN6000mm |

| Accuracy | ±1% |

| Temp. range | -20~350℃ |

| Pressure | Medium pressure≤10MPa |

| Flow rate | 0.1-100m/s |

| Protection | IP67 (sensor part) |

Benefits:

- No need Temperature and pressure compensation; the measurement process is simple and accurate.

- Could measure mass flow or standard volume flow rate of gas.

- Range ratio 100:1, could measure gas flow from 100Nm/s to 0.1Nm/s, and be used for gas leak detection.

- Good vibration resistance, long service life. No moving parts or pressure detecting parts, accuracy will not be affected by vibration.

- Easy installation and maintenance.

- Adopt an overall digitizing circuit measurement to ensure high accuracy.

- The flow meter is with RS-485 communication, which could be part of the automation and integration of your facilities.

Specifications

| Medium | All gases (except acetylene) | |||||

| Pipe diameter | DN10-80 (Flange type) | DN50-6000 (Insert type) | ||||

| Flow rate | 0.1-100m/s | |||||

| Accuracy | ±1%~±2.5% | |||||

| Operating temp. | Sensor | Default type: -10~+200℃ High temp. type: -10~350℃ | ||||

| Transmitter | -20~+45℃ | |||||

| Operating pressure | Medium pressure≤10MPa | Medium pressure≤2.5MPa | ||||

| Power supply | Compact type | DC24V or AC220V≤18W | ||||

| Remote type | AC220V≤19W | |||||

| Response time | 1s | |||||

| Output | 4-20mA | Optical isolation, max. load 500Ω | ||||

| RS485 | Optical isolation | |||||

| HART | ||||||

| Alarm | Option(1-2 alarm、10A/220V/AC 5A/30V/DC) | |||||

| Pipe material | Carbon steel, stainless steel, plastic, etc. | |||||

| Display | Compact type: 4 lines LCD display | |||||

| Display content | Mass flow, standard volume flow, accumulated flow, time, accumulated time, medium temp., standard flow, etc. | |||||

| Ingress protection | IP67 (sensor part) | |||||

| Sensor material | Stainless steel | Stainless / carbon steel | ||||

Thermal Mass Flow Meter Working Principle

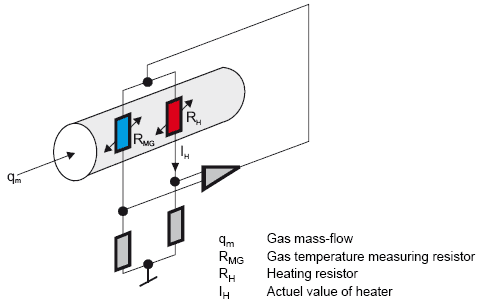

A thermal gas mass flowmeter is a meter that measures the mass flow of gas using the principle of heat conduction. The sensor of the thermal mass flowmeter consists of two reference thermal resistors (platinum RTD). One is the mass speed sensor T1, and the other is the temperature sensor T2 that measures the temperature change of the gas.

When these two RTDs are placed in the measured gas, the sensor T1 is heated to a constant temperature difference above the gas temperature, and the other sensor T2 is used to sense the temperature of the measured gas.

As the mass flow rate of the gas increases, the airflow takes away more heat, and the temperature of the sensor T1 decreases. To maintain a constant temperature difference between T1 and T2, the heating power of T1 must increase.

According to King’s law of thermal effects, there is a certain mathematical relationship between heating power P, temperature difference △ T (T1-T2) and mass flow Q.

P / △ T = K1 + K2 f (Q) K3

K1, K2, and K3 are constants related to the physical properties of the gas.

Read more about: Thermal Mass Flow Meter Technology

Featured Applications

Thermal gas mass flow meters are widely used in fields and industries where high accuracy and stability in gas flow measurement are required.

- Public Utilities

Biogas; coal gas; natural gas; liquefied petroleum gas (LPG); boiler preheating air.

- Oil and Gas Industry

Energy exchange; well filler gas recovery; fuel gas metering; gas quality analysis; leak detection; natural gas measurement; flare gas monitoring.

- Power Industry

Gas measurement during gas distribution in fuel systems; measurement of various gases in boilers and auxiliary systems; gas measurement in gas-fired furnaces; hydrogen measurement; measurement of primary and secondary air in power plant blast furnaces.

- Chemical Industry

Flue gas circulation monitoring; gas flow measurement in sampling systems; gas flow measurement in induced draft fans; ammonia measurement in fertilizer plants; measurement of various gas flow rates in battery factories.

- Metallurgical Industry

Gas measurement in steel plants; blast furnace gas measurement in ironmaking plants; coke oven gas measurement in coking plants; measurement and control of fuel gas (blast furnace gas, coking gas, natural gas, etc.) in steel rolling mills; control of hydrogen, oxygen, nitrogen, and other gases in heat treatment quenching furnaces, etc.

- Pulp and Paper Industry

Gas measurement in wastewater treatment systems; flue gas flow monitoring; boiler secondary/tertiary air recovery; boiler fuel gas and air supply measurement.

- Food and Pharmaceutical Industry

Fresh air introduction during processing operations; carbon dioxide treatment in breweries; hot air flow rate in bottle sterilizers; gas flow rate measurement during thermal oxidation; ventilation systems; boiler intake, exhaust gas, and process control.

- Environmental Protection

Gas measurement during biogas utilization; chlorine gas measurement during chlorine treatment; gas measurement in aeration tanks during wastewater treatment; monitoring of SO2 and NOx emissions from chimney exhaust.

- Other Industries

Compressed air measurement in factories; pulverized coal combustion process pulverized gas/air ratio control; hot gas flow control from vertical grinding mills in the cement industry.

| Industry | Application Description | Typical Case Studies |

| Chemical Process Control | Monitor the feed flow rate of reaction feedstocks (such as hydrogen, oxygen, methane, and other gases) to ensure precise reaction ratios, preventing raw material waste or uncontrolled reactions. | At a petrochemical plant’s hydrocracking unit, thermal mass flow meters control hydrogen injection to ensure crude cracking efficiency while preventing safety risks from excessive hydrogen. |

| Natural Gas/Gas Metering | Used for flow measurement in natural gas extraction, transmission, and urban gas distribution networks, particularly suited for low-pressure, high-flow gas monitoring with accuracy up to ±1%. | In residential pressure regulating stations operated by urban gas companies, thermal mass flow meters measure household gas consumption, replacing traditional volumetric flow meters and reducing metering errors caused by pressure fluctuations. |

| Energy Recovery and Exhaust Gas Monitoring | Measures exhaust gas flow (e.g., flue gas, waste heat recovery gas) from boilers and incinerators to calculate thermal efficiency or pollutant emission concentrations (requires integration with component analysis). | At a waste incineration plant’s flue gas treatment system, thermal mass flow meters continuously monitor gas flow rates. Combined with sensors, they calculate total dioxin and NOx emissions to meet environmental standards. |

| Pharmaceutical Fermentation and Synthesis | Monitors sterile air and oxygen feed rates in fermentation tanks, which influence microbial growth rates and pharmaceutical yields (e.g., antibiotic and vaccine production). | In a vaccine manufacturer’s CHO cell fermentation tanks, sanitary-grade thermal flow meters regulate oxygen flow to maintain stable cell density and ensure vaccine potency compliance. |

| Food and Beverage Processing | Measure flow rates of food-grade gases (e.g., carbon dioxide for carbonated beverages, nitrogen for fruit/vegetable preservation) or liquids (e.g., syrups, fruit juices) to prevent contamination. | At a cola factory’s carbonation process, thermal mass flow meters precisely control CO₂ injection to guarantee consistent carbonation levels in every bottle. |

| Medical Gas Delivery | Monitor oxygen and nitrous oxide (N₂O) flow rates in hospital central oxygen supply systems and anesthetic gas delivery to ensure patient respiratory safety. | In the ICU of a tertiary hospital, thermal flow meters embedded in oxygen pipelines display real-time patient oxygen flow rates and trigger automatic alarms during abnormalities. |

Thermal Mass Flow Meters Types

Thermal mass flow meters are mainly classified into two types: thermally distributed and thermally diffused. They can also be further classified according to installation method and working principle.

Classification by Measurement Principle

- Thermally Distributed Mass Flow Meter: Utilizes the heat transfer caused by gas flow, measuring gas flow rate by changing the temperature distribution along the measured pipe. Suitable for measuring small flow rates in small-diameter pipes.

- Thermally Diffusion Mass Flow Meter: Based on thermodynamic principles, often called a King’s flow meter, suitable for measuring larger flow rates. It determines mass flow rate by measuring the heat exchange between the fluid and a heat source.

Classification by Installation Method

- Insertion Flow Meter: The measuring probe is inserted into the pipe containing the fluid to be measured. Suitable for flow measurement in large and medium-sized pipes.

- Pipe Section Flow Meter: The measuring probe is fixed within a section of standard pipe. Suitable for applications requiring connection to an actual fluid pipeline.

Order Guide

In addition to regular products, we support customization

| SI-3501 | Thermal mass flow meter |

| Sensor type | C Retrench pattern insert type |

| D Online pluggable type | |

| E Flange pipe type | |

| F Thread pipe type | |

| G Clamp on type | |

| Pipe diameter | C Round pipe: DN15~DN6000 |

| S Square pipe: 25*25mm~2000*2000mm | |

| Housing material | A SUS304 |

| B SUS316 | |

| C Other material | |

| Pressure | S 1.6MPa |

| M 2.5MPa | |

| T 4.0MPa | |

| Temp. | I 10~200℃ |

| II 10~400℃ | |

| Output | 1 4-20mA |

| 2 RS485 | |

| 3 PULSE | |

| 4 Relay contact | |

| 5 HART | |

| Power | DC 24VDC |

| AC 220VAC | |

| Display | J Integrated display |

| S Split display |

FAQ

More Flow Measurement Solutions

Thermal gas mass flow meters are used in process control. They require no temperature or pressure compensation and directly measure the mass flow rate of fluids.

Sino-Inst’s thermal gas mass flow meters have no moving parts, low pressure loss, wide rangeability, and high accuracy. They are currently widely used in petroleum, chemical, semiconductor, medical instrumentation, bioengineering, combustion gas control and distribution, environmental monitoring, precision instruments, scientific research, metrology, food, metallurgy, and aerospace industries.

If you need gas flow monitoring, please feel free to contact our sales engineers!

Thermal Mass Flow Meter - Best Price from the Manufacturer

Read more about: Thermal Mass Flow Meter Technology

Product SKU: Thermal Mass Flow Meter

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 590

Price Valid Until: 2099-09-09

Product In-Stock: InStock

5

-1.jpg)