Magnetostrictive Level Sensor adopts the principle of magnetostriction and is an intelligent multi-parameter liquid level meter specially developed for oil storage and transportation management and refining. Magnetostrictive Level Sensors can measure the temperature of multiple interfaces and storage liquids.

The liquid level sensor specially used for gas stations is the Magnetostrictive Level Sensor. If it is an underground oil tank, a Magnetostrictive Level Sensor is installed inside the oil storage tank. The oil level is directly displayed on the liquid level monitor. No manual measurement is required, and the oil quantity monitoring of multiple oil tanks can be realized remotely.

Technical Parameters

| Maximum allowable indication error: | ±0.5mm; |

| Repeatability: | ±0.2mm; |

| Ambient temperature: | -40℃~60℃; |

| environment humidity: | 0~98%; |

| Work pressure: | ≤1.6MPa; |

| The liquid level gauge is placed in a dangerous area, explosion-proof sign: | Ex ibIICT6Gb |

| Maximum transmission distance of liquid level gauge signal: | 300m; |

| Oil level measurement height range: | 5000mm; |

| Minimum measured water level height: | 12.7mm; |

| Oil tank tightness test: | Accuracy 0.38L/h |

| Monthly Leakage Testing: | Accuracy 0.76L/h |

| Communication mode | RS485 |

| Protection level | IP68 |

| How to measure oil temperature: | RTD 5-point oil temperature measurement; single-point oil tank temperature measurement. |

| Applicable media: | Gasoline, diesel, light oil, heavy oil, alcohol mixture, liquefied petroleum gas. |

| Intrinsically safe parameters: Power supply terminal to ground: Ui=12.6V, Ii=291mA, Pi=1.2W, Ci=8.09μF, Li=0; 485 signal to ground: Ui=7.14V, Ii=147mA, Pi=1.2W, Ci=0μF, Li=0 | |

How does a magnetostrictive level sensor work?

The core sensitive element (waveguide wire) of the magnetostrictive sensor is a rare earth super magnetostrictive material. It has the advantages of high strain value and strong electrical (magnetic)—–mechanical wave conversion ability. It can convert small magnetic field vector changes into mechanical waves.

The sensor consists of three parts: an electronic probe, a stainless steel rod (built-in rare earth supermagnetic stretchable wire) and a floating ball (built-in magnet).

When the electric pulse generated by the pulse generator in the electronic probe is transmitted along the waveguide wire in the steel pipe, the electric pulse is accompanied by a ring-shaped magnetic field perpendicular to the waveguide wire that is transmitted along the waveguide wire at the speed of light.

When the electric pulse ring magnetic field meets the float’s inherent magnetic field, the magnetic field vectors of the two are superimposed to form a spiral magnetic field. Instantaneous torque is generated and a mechanical torsion wave is formed on the waveguide wire and transmitted back to the electronic probe at a certain speed, causing induction pulses to be generated at both ends of the coil.

By measuring the time difference between the triggering electrical pulse and the induction pulse generated by the return of the torsion wave, the measured liquid level height can be calculated. The temperature sensor embedded in the measuring rod can measure the temperature of the medium.

Diesel-Fuel-Oil Level Monitoring System

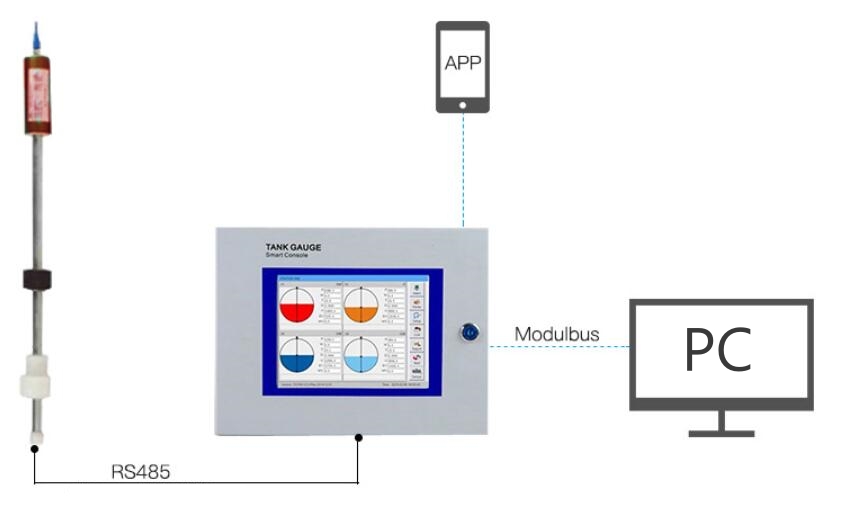

Liquid level monitoring can be achieved by configuring an intelligent liquid level monitor for one or more magnetostrictive level sensors. Here we take the oil level monitoring system of a gas station as an example to introduce it.

The intelligent liquid level management system of gas stations is an intelligent system that measures the liquid level, capacity and other data in oil tanks and storage tanks, and manages the daily import, sales and storage of gas stations.

The gas station intelligent liquid level management system consists of intelligent magnetostrictive probes, intelligent monitors, explosion-proof data display screens and liquid level measurement system software.

The probe uses magnetostrictive technology and can measure the oil level, water level and real-time temperature in the oil tank;

The intelligent monitor automatically collects and processes probe data, and uses scientific calculation methods to provide gas stations with a complete management plan for the purchase, sale and storage of oil products.

System Features:

- Automatically measure the oil level, interface, density and temperature parameters of the oil tank and automatically calculate the tank storage capacity;

- Able to generate import, sales, inventory and alarm reports, which can be queried and printed;

- Able to set high and low alarms, high water level alarms, high temperature alarms, etc.;

- Able to monitor multiple oil tanks in real time at the same time;

- 8-inch color touch screen, color graphics and text display;

- Equipped with 2 relay output interfaces, which can be connected to outdoor explosion-proof sound and light alarms;

- Equipped with RS485 output interface, which can control the oil spill prevention device and intelligent output module;

- Can open communication protocols and provide data support for third-party software;

- Supports remote monitoring and realizes real-time query of data from remote computers or mobile phone clients through the Internet;

- It has a density measurement interface that can be connected to an external density sensor to measure oil density in real time;

- When refueling is stopped, it has an oil theft alarm function;

- Equipped with alarm and video surveillance linkage display functions;

- Double-layer oil tanks and pipeline leak detection sensors can be connected externally;

- Connect the data collector to read the tanker data to generate or correct the tank filling table.

- With equipment fault self-diagnosis function;

magnetostrictive level sensor installation

1. The probe is installed on the upper part of the flange, and the red part is about 30 cm higher than the flange.

2. Add a 3.5cm observation port on the flange for observation.

3. The probe is installed entirely under the flange.

Applications

- Magnetostrictive Level Sensor can be used as gas station level gauge, underground tank level gauge, oil level gauge, diesel engine unit level gauge, etc.

- It can also be used for oil-water interfaces and other interfaces.

- Liquid level monitoring in production processes such as petroleum, chemical industry, metallurgy, electric power, light industry, food, etc.

- Optional anti-corrosion material for level measurement of corrosive chemical liquids.

More Industrial Level Transmitters and Measurement Solutions

Magnetostrictive Level Sensor is designed using advanced magnetostrictive technology and digital electronic technology, and uses digital communication to accurately measure oil level, water level, density and multi-point temperature in the oil tank. Magnetostrictive Level Sensor has outstanding advantages such as high measurement parameter accuracy, complete data, strong anti-interference ability, strong environmental adaptability, reliable data, and scientific and advanced algorithms.

The Magnetostrictive Level Sensor produced by our Sino-Inst supports the customization of various parameters, including: range, material, temperature, pressure, signal output, etc. With the best price! After equipped with an intelligent liquid level monitor, it is widely used in oil, diesel and other storage tank liquid level monitoring in various industries. If you need to purchase Magnetostrictive Level Sensor, or have related technical questions, please feel free to contact our sales engineers!

Magnetostrictive Level Sensor for Diesel-Fuel-Oil Level Monitor

Magnetostrictive Level Sensor for Diesel-Fuel-Oil Level Monitoring. Equipped with intelligent level monitor, suitable for (gas station) gasoline, diesel, alcohol, methanol, and chemical liquids.

Product SKU: Magnetostrictive Level Sensor for Diesel-Fuel-Oil Level Monitoring

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 690

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)