Beer brewing is an artistry that needs exactitude at each and every step of operation. By providing accurate readings, brewery flow meters help individual and professional brewers accomplish the desired balance of flavor and alcohol content in their beer, making them a staple in efficient brewing operations.

Every component of a beer brewing system that contacts consumable media requires sanitary solutions. Beer brewing processes such as mash transfer, wort boiling, and fermentation control require sanitary flow meters. Here comes the role of the food grade flow meter.

Food Grade Flow Meter definition

Food grade flow meter is an indispensable device used in the food and beverage industry that complies with food safety standards and regulations. It measures the flow rate of various liquids accurately. These meters ensure that production processes maintain the integrity of products while optimizing efficiency.

Fundamental features of food grade flow meters

- Corrosion Resistance

- Clean-in-Place (CIP) Compatibility

- Certifications: Food grade flow meters are often certified to meet international standards like NSF, 3A, or EHEDG, which certify their safety for food and beverage contact.

- Non-reactive

- Express clamp installation

Beer brewing flow meter’s requirements

Inline beer flow meters must possess certain qualities to function effectively in beer production. It ensures that one can make an informed decision when selecting a flow meter suited to their brewing operations.

Every flow meter component that contacts the media is made from materials that comply with food safety standards.

These components can endure sudden temperature changes and resist corrosion from cleaning agents like steam, alkaline water, and hydrogen peroxide.

In filling operations, the flow meter is required to react quickly and provide precise measurements.

It is designed to function in cold (approximately 2 °C) and damp conditions.

Kinds of food grade flow meters

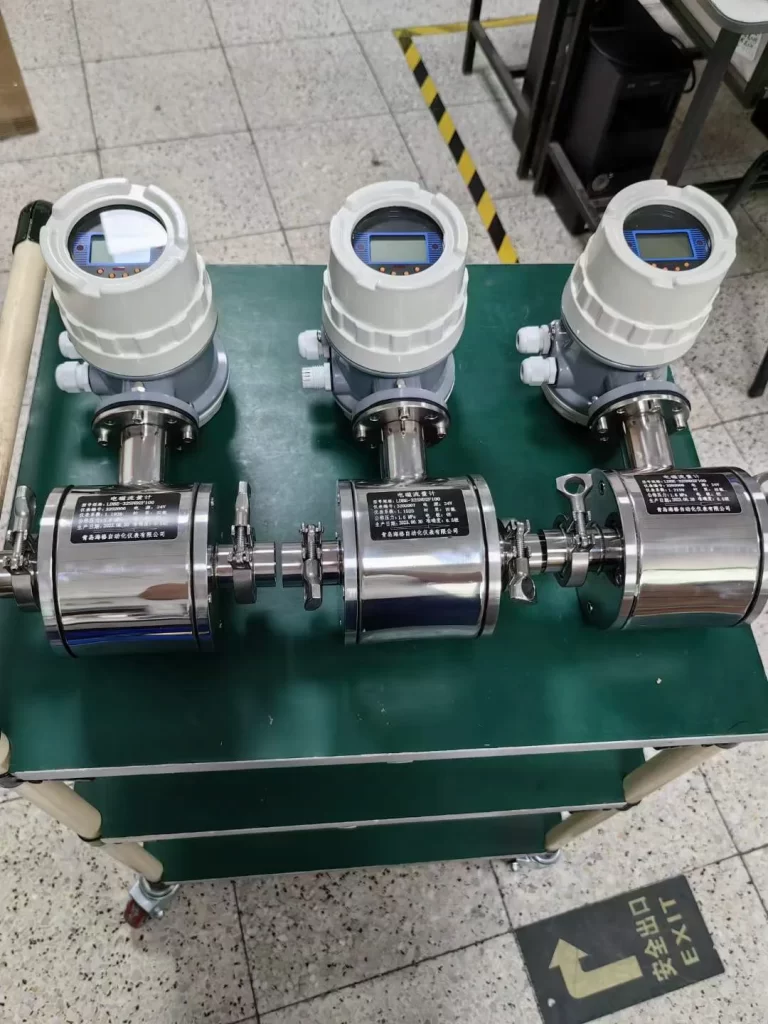

Magnetic Flow Meters

Electromagnetic flow meters, or mag meters, utilize Faraday’s Law of Electromagnetic Induction to determine the flow rate of electrically conductive liquids within a pipe. They are composed of a non-magnetic, insulated pipe, with electrodes and coils arranged to create a magnetic field.

These meters are well-suited for water-based solutions, such as wort, beer, and water used in brewing.

Benefits:

- Suitable for large-scale brewery operations.

- Hygienic and easy to clean, making them ideal for use in food and beverage applications.

Limitations:

- Only works with conductive liquids, limiting their use in some applications.

- More complex to install and calibrate than simpler flow meters.

Coriolis Flow Meters

Coriolis flow meters are well thought out one of the most accurate types of flow meters available. They measure mass flow directly by detecting the force exerted by the fluid as it flows through a vibrating tube.

This technology is ideal for applications in breweries, as it can measure both liquid flow and density, which is particularly useful for determining alcohol content in beer.

Benefits:

- Extremely accurate, even with high viscosity liquids.

- Measures mass flow, which is beneficial for applications like alcohol content measurement.

- No moving parts, reducing maintenance and downtime.

- Provides real-time data that helps monitor the fermentation process.

Limitations:

- More expensive than other types of flow meters.

- Can be sensitive to changes in temperature and pressure.

Positive Displacement Flow Meters

Positive displacement (PD) flow meters are ideal for low-flow and high-accuracy applications. They work by trapping a specific volume of liquid in a chamber and counting the number of times the chamber fills and empties. This makes them particularly useful for precise measurement of ingredients or small batch brewing.

Benefits:

- Extremely accurate at low flow rates.

- Suitable for viscous liquids and accurate measurement of small quantities.

- Provides a direct measurement of volume.

- Can be a purely mechanical flow meter.

Limitations:

- Moving parts can lead to wear and tear.

- May require more frequent maintenance.

Turbine Flow Meters

Turbine flow meters operate by using a rotor that spins in proportion to the flow rate of the fluid passing through it. The movement of the rotor is sensed electronically, and the data is then converted into a flow rate measurement. Despite having moving parts that contact the fluid, turbine flow meters do not have significant pressure drops.

These meters are ideal for measuring large quantities of beer, wort, and water, and they offer good accuracy and repeatability.

Benefits:

- Accurate and reliable at high flow rates.

- Good for continuous flow applications.

- Relatively low cost compared to Coriolis or mag meters.

Limitations:

- Moving parts can lead to wear, requiring maintenance.

- Not suitable for highly viscous or slurry-like liquids.

Sanitary Metal Rotor Flow Meter

Sanitary metal tube rotor flowmeter can be widely used in gas and liquid flow measurement. There are many measurement forms for users to choose from. According to the output form, there are local indication types, remote transmission output types, and control alarm types.

Benefits:

- Low requirements for front and rear straight pipe sections

- The pointer indicates the instantaneous flow, and the LCD double-row display shows the flow and cumulative total (optional)

- All-metal structure, suitable for high temperature, high pressure and highly corrosive media

- Alarms can be set (with alarm type)

Limitations:

- Not suitable for viscosity fluids

- Sensitive to mechanical vibration of pipelines, not suitable for strong vibration places.

Choosing the Right Flow Meter for Your Brewery

When selecting a beer flow meter or brewery flow meter, there are several factors to consider to ensure that you choose the right technology for your application:

- Accuracy and Precision

- Viscosity of the Liquid

- Cleaning and Hygiene Requirements

- Flow Range

- Maintenance and Durability

- Pressure

- Temperature

- Power and signal output

More Flow Measurement Solutions

- An Extensive Guide On Magnetic Inductive Flow Meters

- Flow Measurement For Powders And Granular Materials: Solid Flow Meter

- Rotameter vs Flow Meter

- Metal Tube Rotameter: Working Principle and Applications

- Rotameters: Excellent Choice for Flow Measurement in Various Gases

- High Accuracy Flow Meters: A Key To Precision In Flow Measurement

- Guide for High Pressure Flow Meters – Industrial Liquid & Gas Measurement

- Solution For Low Flow And Low Volume Applications: Low Flow Meter In Detail

- BTU Meter Optimizes Energy Efficiency of Hot and Cold Water Systems

- Turbine Water Flow Meter: A Versatile And Reliable Choice For Water Flow Measurement

- Pulse Output Flow Meters for Better Water Flow Measurement

- Ultrasonic Clamp On Flow Meter – For Easier Water Flow Measurement

The right flow meter is an essential tool for any brewery, whether you’re producing craft beer in small batches or operating a large-scale brewery.

By choosing a food grade flow meter, brewery flow meter, or beer flow meter tailored to your specific needs, you can keep tight control over your brewing process and produce extraordinary beer with every batch.

Sino-Inst is a trusted destination for various food grade flow meters, mainly consisting of magnetic and turbine flow meters. If you need to purchase Food Grade Flow Meters or have related technical questions, please feel free to contact us!

-1.jpg)