Chlorine is an extremely reactive element and a strong oxidizing agent. The gas is greenish yellow in color. It is easy to compress and can be liquefied into a clear amber coloured liquid.

As a corrosive and aggressive gas, the flow measurement of chlorine is a difficult job. Aggressive chemical element bring an element of difficulty to find an appropriate instrumentation for an application.

Many flow meters are not offered in materials that can handle challenging media. Chlorine flow meters allow industries to measure and monitor the precise flow of chlorine gas or liquid, which is essential for various processes. In this guide, we will look into chlorine flow meters in detail.

Challenges of Chlorine Flow Measurement

- Corrosiveness

- Sensitivity to Pressure and Temperature

- High Toxicity

- Chemical properties

Types of Chlorine Flow Meters

Different flow meters are designed for measuring chlorine, depending on its phase (liquid or gas), pipeline configuration, and the specific requirements of the application. Let’s look at the main types:

1. Thermal mass flow meter

Thermal mass flow meter with PTFE painting probe or ceramic probe is suitable for most gas flow rate measurement, especially suitable for aggressive gas, such as Chlorine.

Features:

- Teflon painting probe for corrosive gas flow measurement;

- Ceramic probe for high temperature, also corrosive gas flow measurement;

- No external temperature and pressure compensation/correction to get standard volumetric flow;

- Electronic output 4-20mA/pulse for remote system integration;

- Insertion probe or in-line type thermal mass flow meter;

- Digital display to show instant flow or totalized flow;

- Flow units available: Instant flow units available such as SCFM, g/min,g/s, Kg/min, Kg/h, Nm3/h, Nm3/min, NL/h, NL/min;

- Total flow units available such as CFM,g, Kg, Nm3, NL;

- Can measure aggressive gas at low pressure;

- Option with temperature indication, also temperature indication or output;

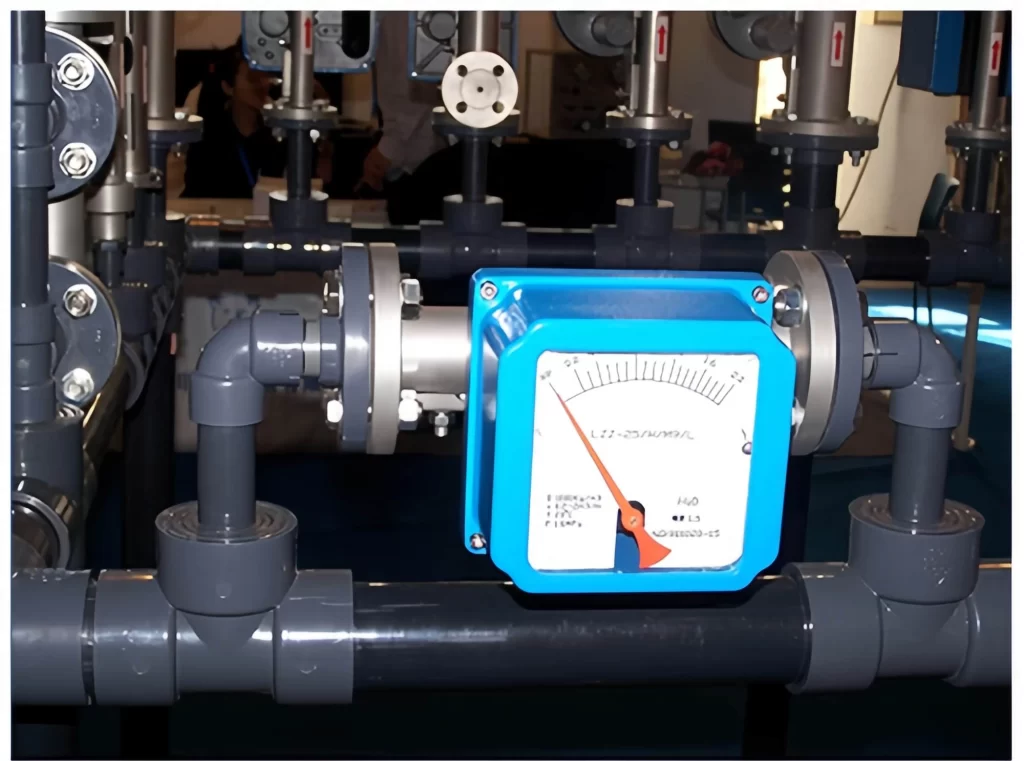

2. Rotameter (Variable Area Flow Meter)

A rotameter is a simple and cost-effective flow meter used for measuring the flow of gases and liquids, including chlorine. It consists of a tapered tube with a float inside that moves up or down based on the flow rate. The position of the float is read against a scale to determine the flow rate. Rotameters are best suited for small to medium flow rates of chlorine in liquid or gas form.

Rotameter is the most commonly used device for chlorine gas flow measurement. The metal tube Rotameter is a kind of variable area flow meter; it can be used to continuously measure the volume flow of liquid and gas in a closed pipeline.

Features:

- Simple design and easy to install;

- No power supply required (mechanical operation);

- Suitable for low to moderate chlorine flow rates;

- Variable Area flow meter has a solid structure and reliable measurement;

- It can be adapted to the measurement of various complex occasions. It is widely used in flow measurement and industrial process control;

- Rotameter has many material options, such as 304 stainless steel, 316 stainless steel, or PTFE lined material for corrosive liquid, such as chlorine;

- Rotameter can be a local flow indicator without any power supply; it can also be equipped with flow transmitters to have an analog 4-20mA output;

- It can even be used with the HART protocol for process control. This kind of digital rotameter with LCD display to show the flow of chlorine gas (Cl₂) instant flow and total flow;

Main limitations are:

- Accuracy can be affected by changes in temperature or pressure;

- Limited to smaller pipelines;

3. Electromagnetic Flow Meters (Mag flow meters)

Mag flow meters can be selected with PTFE lining or PFA lining for liquid chlorine flow measurement. The Teflon and PFA linings are very resistant to corrosion. The electrode materials can be selected from Hastelloy alloy, platinum rhodium, Tan, titanium, etc.

These metals can meet most corrosive properties. The flow meter housing can be selected from stainless steel 304 or 316 to accommodate flow measurements in corrosive environments.

Features:

- Suitable selection of mag flow sensor lining and electrode materials for aggressive liquid measurement;

- There is no obstruction in the measuring pipe, so there is no additional pressure loss;

- There are no moving parts in the measuring pipe, so the sensor has a very long life;

- Bi-directional measurement system for measuring forward flow and reverse flow;

Main limitations are:

- Requires electrical power to operate;

- More expensive than simpler flow meters;

Factors to Consider When Choosing a Chlorine Flow Meter

When selecting a chlorine flow meter, it’s important to consider the following factors:

1. Chlorine Form (Gas or Liquid).

2. Flow Range

Different flow meters have different ranges. If you need to measure very low or high chlorine flow rates, make sure to select a meter that can handle those extremes. Meters like rotameters are best suited for low to moderate flow rates, while electromagnetic meters are more suitable for high flow rates.

3. Pipe Size

The size of your pipe will influence the type of flow meter you need. Some meters, like rotameters, are best suited for smaller pipes, while others, like electromagnetic Flow meters, can be used for larger diameter pipes.

4. Accuracy and Precision

Depending on the application, accuracy may be critical. For example, in water treatment or chemical manufacturing, precise chlorine dosing is vital. In such cases, choosing a high-accuracy flow meter, such as an electromagnetic Flow meter, would be ideal.

5. Environmental Conditions

Chlorine is often used in harsh environments, and the flow meter must be capable of withstanding such conditions. This includes dealing with corrosive chlorine, extreme temperatures, and pressures. Always ensure that the material of construction for the flow meter is compatible with chlorine, such as selecting meters with stainless steel or special coatings for corrosion resistance.

6. Maintenance and Durability

Since chlorine can be a corrosive substance, the longevity of the flow meter is crucial. However, it’s important to consider the potential cost of replacement parts and overall system longevity when making a selection.

More Flow Measurement Solutions

- How To Calculate Pressure From Flow Rate And Vice Versa

- Non-Contact Flow Meters: An Advanced Approach To Fluid Measurement

- Relationship Between Pressure And Flow Rate: Key Insights

- High Accuracy Flow Meters: Technology, Applications, And Benefits

- Right Flow Meter For Molasses

- Mechnical & Digital Kerosene Flow Meters

- Understanding Asphalt And Bitumen Flow Meters

- Liquid Flow Controller-Flow Meter | For Process Liquids

- Extreme Temperature Flow Meters: Accurate Flow Measurement In Harsh Environments

Chlorine flow meters are indispensable tools for ensuring that chlorine is measured accurately and safely in a variety of applications. Whether in water treatment, chemical manufacturing, or sanitation, choosing the right flow meter for chlorine can enhance process efficiency, ensure safety, and reduce operational costs.

Finally, it’s important to partner with reputable flow meter manufacturers and suppliers who can provide high-quality, durable products suitable for chlorine applications. Sino-Inst is an excellent partner in the market with high quality, user-friendly flow measurement solutions. Please feel free to contact our sales engineers!

-1.jpg)